Soapmaking is an art form AND a science. It requires precise measuring of properly selected ingredients to initiate the saponification process. Temperature and time are also important in the chemical reaction between sodium hydroxide lye, water and oils. Because of its precise nature, mistakes are bound to happen. I have experienced plenty of soapy mess ups and still learn new tricks of the trade when soaping. Soapy mistakes happen to us all! Luckily, there methods to prevent and fix these blunders.

Below are some of the most common soapy mistakes, and ways to fix them. Many of these fixes include rebatching the soap, which involves melting the soap with a small amount of additional liquid. To see this process in action, check out this Soap Queen TV video. Also, check out the Tips & Tricks section of the blog to see a wide variety of in-depth posts about these soapy problems.

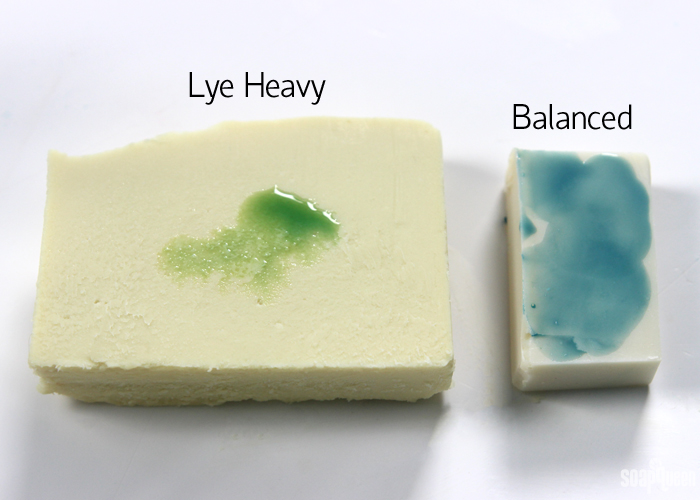

Lye Heavy Soap

When soap is made with too much lye, it is called “lye-heavy.” This means there is extra, free floating lye that was not made into soap during the saponification process. Lye heavy soap can be irritating when applied to the skin and should not be used or sold. Lye heavy soap is often crumbly or dry feeling. If you are worried about your soap being lye heavy, check out this blog post to test the pH using strips, cabbage or even your tongue.

The soap on the left is lye heavy; the pH was tested using the red cabbage method shown in this post.

The soap on the left is lye heavy; the pH was tested using the red cabbage method shown in this post.

How to Fix it:

Once soap has gone through the saponification process, it cannot be reversed. But don’t throw your lye-heavy soap away! Lye heavy soap can be made into laundry soap. Clothes are not delicate and sensitive like our skin, and are not affected by the extra lye in the soap. In fact, soap with little to no superfat is recommended for use in the laundry. Click here to learn about how to turn your lye-heavy soap into usable laundry soap.

Soft Soap

For most recipes, soap needs to stay in the mold for 2-3 days. If after 7-14 days the soap is still soft, it is unlikely to harden. Soft, squishy soap can be caused by several factors. One reason may be that not enough lye was used in the recipe. If the soap does not contain enough lye, the oils will not saponify. Another reason for soft soap is there was not enough hard oils or butters (such as coconut oil, palm oil or cocoa butter). Soap made with only soft oils can take an extremely long time to unmold (such as castile soap). Too much water in a recipe can also result in a soft bar of soap.

Adding sodium lactate to lye water helps soap harder faster. The soap on the right does not contain sodium lactate, while the soap on the left does.

Adding sodium lactate to lye water helps soap harder faster. The soap on the right does not contain sodium lactate, while the soap on the left does.

How to Fix it: To speed up the unmolding process for an extremely soft recipe use sodium lactate in the lye water at a rate of 1 tsp. per pound of oils. Click here to learn more about sodium lactate. If the soap has stayed in the mold for 2+ weeks and is still extremely soft, it will most likely not harden. At this point the soap can be used as is although it will not last very long and the lather may be lacking. If too much water was used, rebatching the soap may help cook out the extra liquid.

If you’ve already made your soap and it’s not coming out of the mold, pop the mold in the freezer for 24 hours and then try to gently release the soap. Some soap can take weeks to unmold depending on a variety of factors so you may just have to wait it out too.

Cracking Tops/ Overheating

Soaping with high temperatures (140 °F and above) cause the top of the soap to crack. Heat causes the soap to expand, so much so that a crack can occur (shown below). This is much more likely to happen when the soap recipe contains a high amount of hard oils and butters, such as cocoa butter, shea butter and mango butter. Soap containing additional sugars (such milk) are also more likely to crack, as shown in the coconut milk soap below.

How to Fix it: When the top of the soap cracks, it may be possible to slice off the cracked section of soap. This will depend on the shape of the bars and design. You can alsso spray freshly-cracked-yet-cooled soap with rubbing alcohol, cover the crack with plastic wrap and gently rub the crack out. This minimizes the cracked look and helps adhere the two sides back together. Another option is to rebatch the soap. The extra moisture from the rebatch process may help create a smoother bar. Using cool soaping temperatures prevents cracking, especially when making milk soap. Placing the soap into the fridge or freezer can also help avoid cracks.

Incorrect Fragrance Oil Amount

An incorrect amount of fragrance oil leads to an over-fragranced or under-fragranced bar of soap. If an extremely large amount of fragrance oil is used, the soap could irritate more sensitive skins. Depending on the skin safety of the fragrance oil, you may have to turn the soap into laundry soap. Or, you might just have an over-fragranced bar. This will vary based on each fragrance and its specific usage rate guidelines. Luckily, soap that contains an incorrect amount of fragrance oil is often fine to use! Some people prefer highly fragranced soap, and other prefer fragrance-free products.

How to Fix it: The only way to add more fragrance oil to already made soap is to rebatch. If the soap if underfragranced, add more fragrance oil once the soap has reached the texture of mashed potatoes during the rebatch process. If the soap has been overfragranced, this is a great time to use any soap scraps or rebatch soap you may have on hand. Adding non-fragranced or lightly fragranced soap while rebatching will help the scent become more mild in the final product. To ensure accurate fragrance oil usage, the Bramble Berry Fragrance Oil Calculator makes the process easy! Check out this blog post for step by step instructions on how to use the fragrance calculator.

Too Much Colorant

If too much colorant is used in soap, the soap may lather color. A little colorant goes a long way, especially when using black colorants such as black oxide and Brick Red Oxide. Soap that contains too much colorant is safe to use on the body, but could potentially stain wash cloths. In the Black, White and Gold All Over Cold Process tutorial (shown below), the black oxide gives the soap a slight grey lather. It’s totally harmless, but may be undesirable.

How to Fix it: If the soap has been made, the only way to ‘fix’ this is to chop up the soap into confetti or chunks and embed the over-colored soap into other batches of soap like in this confetti soap tutorial. Typically, a diluted colorant will help prevent over adding too much color. For cold process, add 1 teaspoon of oxide to 1 tablespoon of a carrier oil like Sweet Almond or Olive Oil and mix well using a mini mixer. Begin adding the color into your soap 1/2 teaspoon at a time until your desired color is reached. Adding the color in small increments will help avoid using too much colorant. For more information about coloring your soap (including information about melt and pour), check out this Talk it Out Tuesday: Colorants post.

Ricing/Seizing

Ricing and seizing are usually caused by fragrance oils. Ricing occurs when an ingredient in the fragrance oil binds with some of the harder oil components in the recipe to form little hard rice-shaped lumps (shown on the left). Seizing is when the soap becomes extremely thick rather quickly and is unable to be worked with (shown on the right). Check out the Soap Behaving Badly blog post for more information on ricing, seizing, acceleration and separation.

Ricing is shown on the left, seizing is demonstrated on the right.

Ricing is shown on the left, seizing is demonstrated on the right.

How to Fix it: To avoid ricing and seizing, make sure your fragrance oils have been tested for cold process soap (good news, all Bramble Berry Fragrance Oils are thoroughly tested in soap!) Fragrance oils not meant for cold process soap are the most common reason ricing and seizing occurs. If you experience ricing, the lumps can often by stick blended out of the batter. When doing so, be aware that further stick blending may result in an extremely thick trace. Seizing is a trickier problem to fix. Once the soap has seized, there is no way to return it to a fluid texture. Just glop that soap in the mold and be prepared for an extremely hot gel phase; seizing and hot soap go hand in hand. If the soap is fresh (less than 24 hours old) the Hot Process Hero technique is great way to salvage your batch.

Glycerin Dew (aka: Sweating)

This problem is unique to melt and pour soap. Glycerin is a natural humectant, and is added to melt and pour soap during the manufacturing process. When melt and pour soap is left in the open, glycerin draws moisture from the air and onto the soap. The result is the appearance of moisture, tears, sweating or dew drops on the melt and pour.

How to Fix it: To prevent glycerin dew, allow melt and pour to cool and harden in the mold completely. Once removed, wrap the soap in plastic wrap immediately. This prevents the soap with coming in contact with the moisture in the air. If you live in a humid climate, a dehumidifier can be helpful.. For more tips on preventing glycerin dew, check out this blog post.

Air Bubbles

When stick blending, air bubbles can get caught within the soap batter. Air bubbles do not effect the quality of the soap, but it is an aesthetic issue. Soap containing air bubbles will have small lumps or bumps within the soap, as shown below. Read more about air bubbles in this blog post.

How to Fix it: Unfortunately there is no way to get rid of air bubbles once the soap has been made, other than rebatching or using the hot process hero technique. Luckily, air bubbles are easy to avoid. Pour the lye water over the head of the stick blender to eliminate splashes that can occur. When inserting the stick blender into the oils, “burp” the stick blender by tapping the blender on the bottom of your container. Continue to burp the stick blender each time it is inserted into the soap batter (shown above). Once the soap has been poured into the mold, tap the mold firmly on the counter to release more bubbles that may be in the batter.

Glycerin Rivers

Glycerin rivers can occur when glycerin within cold process soap gets too hot and congeals. This causes the glycerin to form “rivers” or ribbons of glycerin within the soap. Glycerin rivers are slightly transparent and clear. Glycerin rivers are more likely to occur in soap containing oxides, particularly Titanium Dioxide. To learn more about glycerin rivers and how to avoid them, check out this blog post.

Glycerin rivers are all throughout this soap, which was made with titanium dioxide and high temperatures.

Glycerin rivers are all throughout this soap, which was made with titanium dioxide and high temperatures.

How to Fix it: The good news is that glycerin rivers are only cosmetic, and do not effect the quality of soap. To avoid glycerin rivers, decrease your soaping temperatures and/or also decrease the water amount in your soap. Placing the soap into the fridge or freezer to prevent gel phase also prevents glycerin rivers.

Crumbly Soap

Soap with a dry, crumbly texture could be caused by too much lye in your recipe. If your soap has a crumbly texture, ensure it is not lye heavy. If the pH is safe to use, the crumbly texture could also be caused by soaping with cool temperatures. Soaping cool (100 °F or below) can increase the chance of soda ash. Soda ash normally occurs on the top of the soap. If soda ash is deep within the bar, it can cause a crumbly texture. Another cause of crumbly soap is the separation of stearic acids within oils, especially palm oil.

How to Fix it: Soaping around 120°F or above will help decrease the chances of deep soda ash within your bar. To avoid the seperation of stearic fatty acids, be sure to melt down the complete container of palm oil before adding it to your soap. Like all oils, palm oil is made up of various fatty acids. These fatty acids melt and different temperatures. When a portion of palm oil is melted, it may not contain all the necessary fatty acids that your soap requires. The heat resistant plastic bags make melting your palm oil easy; check out this blog post for tips on how to boil the bags as well.

Soda Ash

Soda ash is caused by teensy amounts of unsaponified lye coming in contact with carbon dioxide in the air. While harmless, soda ash causes a layer of white on the top of the soap. Soda ash is an aesthetic issue that is most commonly caused by temperature. To read more about what causes soda ash and remove it, check out this blog post.

How to Fix it: Luckily, soda ash is easy to remove. Steaming the top of the soap is an extremely effective way of removing soda ash. In addition, you can use cold water to simply “wash” the soda ash off (click here to learn how). To prevent soda ash, increase the temperature of your lye and oils to 120°F-140°F. Forcing soap into gel phase is a great way to prevent soda ash! Doing a slight water discount in your recipe, and spraying the top of newly made soap with 99% isopropyl alcohol every 15-20 minutes for the first hour also prevents soda ash.

DOS (Dreaded Orange Spots)

Dreaded orange spots, aka: DOS, is usually caused by rancid oils or butters in your soap. DOS usually appears a few weeks or months after the soap is made. DOS looks exactly like it sounds…orange or rust colored spots on your soap. These spots can appear in one area of the soap, or all over. Soap with DOS my also develop an unpleasant odor.

Dreaded orange spots can appear all over the soap, as shown above.

Dreaded orange spots can appear all over the soap, as shown above.

How to Fix it: Soap with DOS is not unsafe to use, but may look or smell unpleasant. To avoid DOS, be sure to use fresh oils and butters. If you are curious about the shelf life of common soapmaking oils, check out this blog post. Place your oils and butters into the freezer to extend the shelf life. Soap with high superfat of 5% or more is more likely to develop DOS, as is soap in a high humidity climate. Click here to learn more about how to prevent DOS.

Is there a soapy mess up that you’d like more clarification on? I would be happy to write up a blog post about it! Check out the blog posts below for more information about soapy mess

ups and how to prevent them:

Formulating Cold Process Soap Recipes

Dealing with Dreaded Orange Spots

The River Runs Deep: An Explanation of Glycerin Rivers

Soap Behaving Badly

All Olive Oils Are Not Created Equal

Explaining and Preventing Soda Ash

“Why Did my Soap Turn Brown?”

Hot Process Hero

Augh! What’s That All Over My Soap? (Glycerin Dew)

If at First You Don’t Succeed, Soap Soap Again!

Hi

I’m a newbie to soap making and just made my first batch a couple of weeks ago. I only cut the soap today as it stayed too soft for about 5 days, and after that I was away. The soap is still quite soft and when i cut it pieces crumbked off and it also stuck to the knife a lot. The lieces are soft enough for me to stick them back into the main bar though. I tried the ph lick test and it felt fine. It also foamed well when I cleaned my hands afterwards. The soap is more powdery on top than on the bottom. I only got a small amount if trace after about 15min of mixing with the blender. I’m not sure what I’ve done wrong?

I used

1000g olive oil

200g coconut oil

160g lye

390g water

Help?

Thanks

Because your recipe contains a lot of olive oil, it will be softer and take longer to cut! That is normal. Did you use a stick blender to combine it? Also, I’m thinking the crumbly texture may be due to soda ash: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/explaining-and-preventing-soda-ash/

-Kelsey with Bramble Berry

Hi, if ricing occurs in soap and we didn’t blend it out to smooth it, is the soap still safe to use?

As long as there are no lumps that soap should be safe to use! You can pH test it just to be extra careful. Learn how to pH test here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

-Kelsey with Bramble Berry

Hello.I made some homemade cocoa butter body balm using organic bees wax pellets,1/4 cup of Calendula infused oil,1/4 avocado oil and the half cup of cocoa butter that was a solid form when I bought a small jar from a brand company.And I use Lavender organic essential oil of 20 drops instead of 30.I did let everything melt in a glass small Pyrex dish in water that I let boil first. I did stir time to time to help everything melt especially the bee wax pellets. Then I added the 20 drops of the Lavender oil stirred it in and then let it get cooled and get solid. I notice today at the bottom of the underside looking at the bottom of the glass small dish was water! I was thinking,how water get in if I didn’t use water? The balm was hard though and when I was applying it on my skin I held the bowl open toward my little electric heater to get it to soften then apply to my skin.Of course it will form to become hard again.The top on the dish is rubber. I thought maybe somehow condensation of moisture developed when I was heating it up and the moisture was at the bottom of it .I see only when I look at the underside of the dish.I then decided to crack it up to break up the balm in chunks to see more.Then I saw white covering it too.Is it MOLD? If it is I cannot use it and have to through it out.Why the moisture developed in my cocoa butter body balm ? Help!

Hmm, I’m not quite sure why that happened! Is your lavender all oil, or does it have any alcohol or water in it? Did you add any extra ingredients like honey or glycerin? Let me know and I’ll help you out. 🙂

-Kelsey with Bramble Berry

Lavender Absolute

Unlike all of the other lavenders, Lavender Absolute is not steam distilled. It is carefully alcohol exracted to highlight the rare and alluring compound called coumarin which gives the Absolute a sweet, grassy aroma with nutty undertones. This rich, verdant oil is FOR PERFUME USE ONLY. Can be used singly or in a blend. Try it mixed with Vetiver, Neroli, Cocoa Perfume, Vanilla, or Sandalwood.

Constituent Profice:44.7% Linalyl Acetate, 28% linalook, 8.1% coumarin, 1.2% Camphor, 0% Limonene, 0% Geraniol, 0% 1,8-Cineol. I purchase my oils from Herbiary store in the city where I live. They specialize in herbs,essential organic certified oils,etc. I did not use honey or glycerin.I have an allergy to Shea butter,that is similar to latex and some reason coconut oil I was itching very badly last week. Coconut oil has an high fat percentage and almond,jojoba oil being a wax I cannot use that either.Caster oil, and vitamin e as well. I only use the cocoa butter that I bought in a plastic jar and used avocado oil from a company named Now,and I used infused Cendulia oil that was in a amber color glass bottle from and herb store that sell mostly soaps, and items for the body that people want that is organic.

I notice the description says the absolute is for perfume use only, so I’m wondering if that may be it! The absolute may be separating because it’s not meant for use in balms. I would recommend making the balm without the absolute to see how that works. If the balm doesn’t separate, it is likely the absolute causing the trouble. You may want to try a skin-safe essential oil intended for balms. 🙂

Essential oils: https://www.brambleberry.com/Essential-Oils-C157.aspx

-Kelsey with Bramble Berry

Pls am Fresh Ebipado from Bayelsa state-Nigeria, a beginner. If I may ask, i was thinking that soaps are to be harden or strong within 2-3 days before packaging and sale. Is there no other ways of making a soap to be strong within 2 or 3 days?. (2) is it how all the soaps in stores left to dry and strong for a month or two, before marketing? Pls reply me via: [email protected]

Cold process soap hardens in about 3-5 days, then needs to cure for 4-6 weeks. That gives you the best results. If you’d like soap that’s ready to use in just a day, I would recommend melt and pour soap! Learn more about it here: http://www.soapqueen.com/bath-and-body-tutorials/melt-and-pour-soap/free-beginners-guide-to-soapmaking-melt-and-pour/

-Kelsey with Bramble Berry

Hello!

I made a batch of CP soap 3 days ago that I believe separated because it got too hot. I had put it in my warmed (and turned off) oven to make sure it gelled. The top got a little bit of an alien brain look so I took it out of the oven. When I went to check it the next day, I noticed there was a bit of oiliness around the sides of the soap, between the soap and the mold. I asked on a facebook group and they said because my recipe used a lot of soft oils, the oil might reabsorb in time. Today I looked at it again, and realized that there are puddles of oil just below the surface of the loaf. I’m thinking about trying to rebatch it. First though I’m wondering if, 1) is there any chance the pools of oil will still reabsorb? and 2) if I do rebatch, should I add more essential oil to the soap? I used Lemon and Litsea Cubeba and I’m afraid there won’t be any smell left after cooking the soap. Thanks! 🙂

When the soap gets too warm, it can get that oiliness. It usually reabsorbs within a couple days at cool room temperature. If it’s still pretty fresh, you may give it another day or two! If not, you can try rebatching it: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/soap-queen-tv-presents-how-to-make-rebatch-soap-2/

You can add more scent if you like. However, you don’t want to go over the strong recommendation on the Fragrance Calculator, otherwise it can irritate the skin: https://www.brambleberry.com/Pages/Fragrance-Calculator.aspx

-Kelsey with Bramble Berry

Hello,

First of all thank you so much for always sharing great information and posting amazing articles.

After months of procrastinating and making M&P soap instead, I finally tried making my first CP soap just 3 days ago. I know I should have avoided any additives at first but I lacked the will power and added ground oatmeal, honey, and FO at medium trace. I was just seconds into mixing the FO gently with spatula, then viola! I had mashed potatoes! Quickly I plopped everything into the mold and placed in the freezer to skip gel phase (was this the right thing to do, for honey?). Placed the soap there for 7 hours, removed from freezer and left it in room temperature (approx 28 degrees C) for 12 hours, then attempted to cut. Sadly, it was so crumbly that it kept breaking apart while cutting. I managed to cut most of it into bars though. Would you say this was because of the FO or simply the amount of lye might have been off? Or shouldn’t I have added the salt as there are high amount of hard oils already? Below is the recipe percentage:

Pure Olive – 32% (230g)

EVOO – 8% (50g)

Palm – 35% (245g)

Virgin Coconut – 15% (105g)

Unrefined Shea Butter – 10% (70g)

(total of 700g oil)

(I ran the recipe on BB lye calculater but as 40% OO.. I ran short on pure OO so I substituted the rest with EVOO that I had on hand)

Lye 92.41g

Distilled water 231g

1 tsp salt in lye water

1.5oz Milk & Cherry Blossom and Tea FO (I mixed the two..)

(less than) 1 tbsp raw honey

2 tbsp ground oatmeal

Soaped at approx 48C for both lye water and oil mix. slick blended and pulsed until medium trace. divided the batter into two. added oatmeal in one and honey on the other. batter was still at medium trace at this point. Poured half of FO on each, mixed a little, then poof! They started getting REALLY thick. I was able to pour the honey one somehow as the bottom layer although extremely thick, but when I got to the oatmeal one it was really thick like a mashed potato. I plopped everything anyway.

Now I’m curing them and hoping for the best. I read on one of your articles that we should wait a few days before zap test so I haven’t done the test yet.. Do you think the soap will be at least usable? or the crumbling a symptom of lye heavy soap and I should just try to make it into a laundry soap? I’m really heart broken.

Thank you so much for reading and hoping for your insight.

Oh and it’s 8% superfat!

I’m thinking it may be soda ash from the salt water. Soda ash forms when unsaponified lye reacts with naturally occurring carbon dioxide in the air. It doesn’t affect the final bar, but it can form ash on the top and make it crumbly. Salt can as well, which is what I think happened. Do you have a picture of the soap you could message to us on Facebook? That way I could take a look and confirm!

Bramble Berry Facebook: https://www.facebook.com/BrambleBerry/

Also, with honey you do want to pop it in the freezer to keep it from getting too hot. Learn more about working with honey here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/adding-honey-to-cold-process-soap-tips-tricks-recipe/

-Kelsey with Bramble Berry

Hi Kelsey,

Thank you so much for your response! Absolutely. I will send the photos now.

Thank you!

Donna

Could you touch base on why my pencil line soaps are falling apart where the pencil line is?its happened twice now and I can’t seem to figure it out and I’m getting quite frustrated

Absolutely. That typically happens when there is too much mica between the layers. It causes them to break apart. It helps to sprinkle a very small amount and then blow to evenly distribute the product. That will help you get a nice line and prevent the layers from separating. It also helps to not get too much color in one area. This tool really helps with that: https://www.brambleberry.com/Powder-Duster-P5427.aspx

Learn more about mica lines in this video: https://www.youtube.com/watch?v=m8ReVwhBCDU&t=438s

-Kelsey with Bramble Berry

I made soap for the first time. When I used them for the first time they left my skin a bit dry. I did the lye test and they are balanced. I wonder if it was my oil mixture. I used 30% coconut. 40% Olive. 6% castor. 2%jojoba. 2% rosehip. 10%cocoa. 10%Shea. 5%super fat. What can I do to make them feel more moisturizing?

Coconut oil is very cleansing. So much so that at a higher percentage, it can feel a bit drying. I would recommend dropping the coconut oil to around 15-20% and increasing the olive oil. That will make the bars more moisturizing on the skin. 🙂

Learn more about formulating cold process recipes here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/formulating-cold-process-recipes/

-Kelsey with Bramble Berry

Hi,

I am not sure why my cured soaps starts dripping oil after a few months. Before that, they were harden and ok to use.

Is that dreaded orange spot or sweating?

How could I save them?

Thanks.

Hmm, I’m not sure why that’s happening! Are the bars developing orange discoloration or an unpleasant smell? How are you storing the soap? Does your recipe have any salt? Let me know and we’ll get this figured out. 🙂

-Kelsey with Bramble Berry

I have made 5 batches of soap they have ALL turned out to badly. In other words they all turned out to soft to take out of the mold. I did use beeswax the first time i made soap so i had to heat up the oils a lot hotter than i would have had to if i hadn’t used beeswax. But in my latest batches I didn’t use beeswax and the same thing happened. every time i add the lye it ether immediately gets so thick I cant use the stick blender or it take FOREVER to trace and instead of tracing it separates there’s always this weird grainy stuff on the top and melted oils underneath after what seems like eternity its will start to thicken up but its like mashed potatoes except is smooth and instead of cooling down is heating up with out me doing anything to it except stirring! I then transition to a wooden spoon and after continuing to stir it turns shiny and more fluffy which is usually when i put it in the mold because it looks like extremely thick patrolium jelly so i assumed it was ready. I have researched this but i cant find anybody who has had this problem. I have tried different recipes i have done hot process but when i try cold process it never traces it just immediately gets to thick to work with. I have researched on how to re-batch but I’m not sure whats wrong with my soap. I did read that if your soap is soft you ether didn’t add enough lye or you didn’t add enough water. I REALLY REALLY REALLY need some help so if you have any tips or advice i am all ears.

I am sorry about that Savannah! My first guess is it may be temperature related or it may be the lye. What is in your recipe? What kind of lye are you using, and how old is it? What temperatures are you using? Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry

Hello! I’m a newbie at soap making but have attempted serval times to make cold process soap and only got one batch of soap that can be used. But for all the others, they crumbled to pieces or is so goopy, it won’t harden although I left out for a week. I’ve waisted so much ingredients already so would like to rebatch. Can I combine the two when rebatching? Please help!!

I’m sorry about that! Can you tell me more about your recipe, including the oils, water and lye used? What temperatures are you soaping at? How long are you stick blending for, and how are you storing the soap? I can help you troubleshoot and find options for your batches now. 🙂

-Kelsey with Bramble Berry

Hello there! I made some CP soap a few days ago. I cut it after 48 hrs and it was very delicate! It was harder than I expected and began crumbling as soon as I pressed down with my knife! It’s sunflower, olive and coconut oil soap. No EO just 5 oz of oats. The SAP isn’t very strong now as it’s been almost a week since I made it. Is it possible that I simply over traced it?

There can be several factors that cause crumbliness, including a lot of hard oils or overheating. How much coconut oil did you use? Also, how hot did you soap, and where did you store the soap?

I would also recommend pH testing it, as the soap can be lye heavy. Learn how to pH test soap here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

-Kelsey with Bramble Berry

Hi dear, I have made about 15 batches of cold process soap of different recipes. I use sodium lactate, titanium dioxide and essential oil. Almost of my batches have good smell at first 4-6 weeks of curing. But then they have a light to strong amonia scent when bathing. I dont know why and feel confuse now. The only batch that still has good scent is not added sodium lactate and titanium dioxide. Please help me out of this.

Hmm, that’s strange! Titanium dioxide and sodium lactate have very subtle smells, so I don’t think they’re causing that smell. What essential oil are you using, and what oils in your recipe? Also, how old are your oils? It may be something else causing that smell! Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry

Hi dear,

The fisrt one recipe is your crisp cotton swirl cold process. The second recipe i used is your perfect palm free for intricate design but i had sunflower oil instead of chia oil/hempseed oil. Ofcourse i have run it through lye calculation. The third one recipe is your beautiful swirl but i used sweet almond instead of hazelnut oil. I buy sunflower oil, pomace olive oil, canola oil from supermarket and they are all in usage time. The others i have just bought from local cosmetic suppliers. My first batch that doesnt have amonia smell uses these oil too. I dont put any milk or any thing like that in my batch. My scale is a good new one. I hardly point out what problem i am facing now.

Because that smell is happening in multiple batches, I’m wondering if it’s the oils. Some oils from the supermarket can sit on the shelf for awhile before being picked up. That means they may be rancid. Do you notice any odd smell from the oils themselves? Or do you see any orange spots on your bars? Thanks for answering my questions!

-Kelsey with Bramble Berry

I have noticed no strange from the oils and butters. My bars are still nice without orange spots. I may now change to another brands and suppliers. Hope it will solve itself. Tks very much for your help.

You’re welcome! You may also try the bars using a different water source (like a public bathroom). It could be natural minerals in the water mixing with the bars and creating that scent. Let me know if the different oils help!

-Kelsey with Bramble Berry

I have made several batches of cold process goat milk soap and all of it is testing lye heavy when I use the cabbage method. I ran my recipe through the lye calculator and used the measurements given. It’s so frustrating trying to figure out where I went wrong. The soap has cured between 1-3 weeks so far. I used castor oil 5%, coconut 30%, olive oil 35%, palm 30%, lye 4 oz, milk 9.24. I could see one batch being heavy but all my batches. Any help would be appreciated!

I’m sorry about that Charity! To be extra careful, I would recommend pH testing the soap using strips. That can sometimes be a bit more accurate than the cabbage juice. Learn more about pH testing soap here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

If you’re finding the soap is 11 pH or higher, it could be your scale. If your scale is off you may be adding more lye by accident. I would recommend calibrating the scale (you can usually find instructions for that in the packet that comes with the scale. Let me know if you think that could be it!

-Kelsey with Bramble Berry

Hi there,

I made a batch of soap in a silicone mold using 100% coconut oil. I wanted a pure white soap so I placed it in the freezer for about 4 hours because I did not want it to go through a gel phase.

This morning I removed it from the mold without any issue but it was still a little soft. I cut through it and while the outside was fine the inside had gone through a gel phase and it was crumbly, but not hard. I thought that by putting it in the freezer I would avoid gel phase and don’t know why it is crumbly.

I used coconut oil at 20% superfat. Tussah silk, Kaolin clay mixed with my essential oils; lavender, rosemary, lemongrass and peppermint. The lye and oils were around 115 degrees when I mixed and it took quiet a while to trace. I tried to mix it to a thick trace as I wanted to decorate the top with a sppon and have a chunky texture. However, I did notice that when I poured my trace liquid into the mold that there were some lumps. I dont really understand what the lumps were. When I poured the lye into the oils I poured it through a sifter just to make sure there was no undissolved lye present.

I love the feel of pure coconut oil soap, it is so creamy and need some pointers as to where I went wrong as I want to make it again.

Would so much appreciate some help.

Hi Birgit!

Hmm, the lumps could be several things! How did you incorporate the clay? It can sometimes cause clumping. Also, how long did you stick blend the soap for? Let me know and I’ll help you troubleshoot. 🙂

Also, the soap may just need a bit longer in the freezer next time! I would recommend leaving it in overnight to help prevent that gel phase!

-Kelsey with Bramble Berry

Hi Kelsey,

I premixed the clay with the essential oils and it seemed well incorporated when I added it at trace. I can’t quiet tell how long I stick blended for but it was most probably twice what I usually do for my other soaps with a combination of oils. Is it possible to overmix? How long does it usually take for coconut oil to trace?

I’m assuming there is no harm done by leaving the soap in the freezer overnight?

I’m still perplexed as to why the soap crumbled. I’ve read about crumbling soap possibly being lye heavy, but when it’s hard, mine was soft. I washed with the soap and it seemed fine. In fact, I love this soap, its so creamy and soft on my hands. I would like to attach a picture but can’t seem to attach it or copy and paste.

Looking forward to resolving my soap dilemma. Thanks so much for your time Kelsey!

I tested the ph of the soap with distilled water and ph strips, 9, which seems close to what it should be?

That pH level is exactly where it’s supposed to be! Handmade soap has a pH of 9-10. Because the bars are balanced, I’m wondering if it just needs a bit more time to harden. If it’s soft and falling apart, a few more days can make it firm up. How much clay did you add? Thanks for answering my questions Birgit! 🙂

-Kelsey with Bramble Berry

1/2 tsp Kaolin clay for 16oz oils. Some soapers swear by it and use it to prolong essential oils??? Any tips on this?

That amount should be just fine! Just to confirm, you waited about 24 hours before cutting the soap? I talked to one of the soapy experts here and it may be that the soap was cut too late. With 100% coconut oil recipe, it is ready to cut in just a couple hours. After that time it can become brittle and more hard to cut. Let me know!

-Kelsey with Bramble Berry

I made the soap at around 3pm and unmolded it at 9am the following morning. The soap was soft and crumbly, not hard and crumbly. It certainly was not hard to slice.

I used a ratio of 2:1 water to lye. Could this have been a factor?

It seems hard to figure out what caused this. What are your suggestions moving forward? I’m determined to make this soap again.

Thank you!

I am sorry, I’m still a bit stumped! One last question (hopefully) – did you notice your lye getting as hot as usual when you mixed it with water? Was it clumping together in the bottle? How old is it?

-Kelsey with Bramble Berry

No problem Kelsey, I appreciate you trying to figure this out for me 🙂

When I add my lye to the water it usually begins at around 200 degrees and then drops somewhat to the mid hundreds then takes a little longer to get below 100.

No, the lye was not clumping together in the bottle. Crafters Choice Lye flakes that I purchased from Bull Apothecary with a coupon. I used the lye about a week ago on another bar of soap with no problem.

My only other solution is to make a sample batch again and diligently record everything I do so that I could maybe pinpoint the issue if there is a problem.

Thank you so much for your help in trying to resolve my soap dilemma!

You’re welcome Birgit, I’m sorry we weren’t quite able to figure it out! If you pinpoint the problem, let us know. I’m curious now! 🙂

-Amanda with Bramble Berry

Is it possible to hot process soap after the fact if the scent didnt turn out the way you wanted? how do you correct fragrance issues after the fact?

You can rebatch the soap to add more fragrance if you like! That involves grating the soap and heating it on the stove. When it’s the texture of mashed potatoes, you can add your fragrance. 🙂

See how to rebatch soap in this recipe: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/soap-queen-tv-presents-how-to-make-rebatch-soap-2/

You can use the Fragrance Calculator to find out how much to use in your recipe: https://www.brambleberry.com/Pages/Fragrance-Calculator.aspx

-Kelsey with Bramble Berry

I just finished a batch of CP soap and have relised I have left out 8% Avocado oil. Will it be any good.

Hi Leonie!

With the 8% oil missing, the soap may be lye heavy. I would recommend waiting 5 days and then pH testing the soap. It should be around 9-10 pH. If it’s higher than that (11-14), the soap can be irritating to the skin. The good news is lye heavy recipes make great laundry soap! 🙂

Learn how to pH test the bars and how to make laundry soap here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

-Kelsey with Bramble Berry

Hello! Recently, I made a couple of batches of CP soap and noticed after washing my hands with them, there is a thin, sticky, oily layer on the soap. Once the soap dries thoroughly, it is fine but it takes longer than normal for the outside layer to harden back up. If someone were to wash their hands right after me, the bar of soap would feel super sticky and slimy and gross! I ended up using the soaps in the shower for myself because they have plenty of time to dry in between uses. But would you know the cause? I used different fragrance oils in the different batches. One used cocoa powder. The ingredients included olive oil, canola oil, coconut oil and Shea butter. I typically soap around 120 degrees. I’m stumped! Thanks for your help!

Hi Angela!

How long are you letting the soap cure? The reason I ask is because when soap cures for 4-6 weeks, it does last a bit longer in the shower and there is less soap residue. Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry

Hi Kelsey, I am curing it for 4-6 weeks So I am not sure why these bars came out like this. The lather is great though… In fact my mom and I are enjoying them but I cannot sell them bc I feel that they are too sticky in between uses if not dried out. It’s almost like they have a shiny, oily, sticky covering on them after use and takes longer to dry out in between uses.

That cure time is exactly what we recommend! What percentage of oils are you using? Soap with a high amount of soft oils will be softer overall and can have a bit more residue. 🙂

-Kelsey with Bramble Berry

Thanks, Kelsey, for your help!the percentages I used were 50% olive, 36% canola, 7% coconut & 7% Shea butter. Maybe I should increase my coconut oil and Shea?… Thanks again!

My other batch was 30% olive, 30% canola, 20% coconut oil & 20% grapeseed oil. 😊 That one was sticky too.

Thanks so much for that recipe! If the soap has a high amount of soft oils, it can feel quite soft or leave some oils on the skin. Those oils are nice and moisturizing! If you prefer a harder bar, I would recommend increasing the hard oils. You can add up to 33% coconut oil and 15% shea butter. You can also decrease your superfat level to around 3%. That helps prevent the “sticky” feeling. 🙂

Read more about formulating cold process recipes here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/formulating-cold-process-recipes/

This post has more information on superfat as well: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/superfatting-soap-an-explanation-2/

Using a draining soap dish can help as well. It keeps the bar dry in between uses!

-Kelsey with Bramble Berry

Great. Thank you! It is moisturizing that is for sure! I guess it’s normal for some soaps to dry longer in between uses depending on the recipe. Thanks again!!

You’re welcome Angela! 🙂

I made a batch of soap that was 500g coconut oil and 500g beeswax, both of which are solids at room temperature. When we went to add them to the lye mixture they both cooled too quickly and became like cake batter (so hard to tell if they saponified and reached trace). We put them in the moulds anyway and when I took them out this morning they had some liquid droplets in them which splashed into my cut and hurt A LOT. My partner wants to melt them down again and add olive oil and try and reach trace. Would this work?

Hi Sarah!

I think you may have gotten false trace! When cooler lye water mixes in with hard oils and waxes, it can start to solidify it before it’s fully emulsified. Because of that, the soap can separate and have pockets of lye water and oils.

I would recommend using the Hot Process Hero method. That uses heat to emulsify the soap: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/hot-process-hero-2/

For the next batch, higher temperatures will help! When working with beeswax, we recommend having the lye water and oils at 170F. Beeswax has a higher melting point so it needs warmer temperatures to ensure it stays melted the whole time. Read more about working with beeswax here: https://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/beeswax-spoon-plop/

It can also help to add soft oils to the batch! Soft oils are oils that are liquid at room temperature. They add moisturizing properties to the recipe, and also help your batch trace more slowly. Olive oil and sweet almond oil are a few options. 🙂

Read more about common soapmaking oils and how much to use in this post: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/free-beginners-guide-to-soapmaking-common-soapmaking-oils/

-Kelsey with Bramble Berry

Well did I ever mess things up. Made 2 different batches of soap. On both batches left out 9.9 oz of olive oil. First batch crumbled second is doing ok,,,,,, however I know it is lye heavy. Can I do a rebatch on it to get the oil in it?

Hi Carolyn!

Oh darn, I’m sorry about that! I have left out oils in my batch before as well. Once I left out palm oil, which was 30% of my recipe. The soap was definitely lye heavy.

Because the recipe has already saponified, rebatching isn’t an option. The oil won’t turn into soap and will likely pool on top of the soap. Then, the soap itself will still be lye heavy and can irritate or burn the skin.

You can use lye heavy recipe as laundry soap though! I’ll include some recipes below. 🙂

Three DIY Laundry Soap Recipes: http://www.soapqueen.com/bath-and-body-tutorials/home-crafts/three-diy-laundry-soap-recipes/

Natural Laundry Soap: https://www.soapqueen.com/bath-and-body-tutorials/home-crafts/natural-laundry-soap-natural-dryer-sheet-recipe/

-Kelsey with Bramble Berry

Hi, I’m a new soaper from the Caribbean and I think that our greatest challenge here is the climate. I soap at room temperature which is about 28 degrees Celcius (average humidity is 80) and Cocount oil is liquid and sold in small necked bottles here. I do however get my fragrances online and I am an avid reader of this blog (fantastic work btw).

My problem has been, glycerin sweat. Last night I made a soap that was Coconut Oil, 76 deg 5 oz, Olive oil, 6 oz, Shea butter, 2 oz, Sunflower oil, 3 oz. I put 2 tablespoons of French green clay and scented with peppermint oil. Today the soap was covered in dew and not quite ready to unmold. CP soaps that I have made in the past have dewed after cure and I’m wondering if its purely a climate problem and that I should wrap my soaps in plastic wrap or if I should reformulate my soap with more hard oils.

Hi Melissa!

Thanks so much for all the recipe information! It’s really helpful. 🙂

I’m thinking the sweating may be due to the hot and humid environment. I checked some online soapmaking forums and people in similar climates were having the same sort of sweating. To be extra sure, I would recommend pH testing the soap. The sweating can also sometimes come from separation. If the soap is separating, there may be lye heavy spots. Find out how to pH test soap here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/test-ph-red-cabbage/

If the soap is around 9-10, it is likely due to the humid climate rather than separation. There are several things you can do to help keep the soap dry though! A dehumidifier can absorb excess moisture and prevent that sweating! You can also put rice or silica packets near the soap for the same reason.

Then, after a 4-6 week cure, I would recommend wrapping the soap tightly in plastic wrap. That helps protect it from humidity and should help keep it dry. 🙂

Learn more about storing your soap here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-store-handmade-bath-products/

-Kelsey with Bramble Berry

Thanks so much for the advice!. I am going to check the pH of 2 different batches of soap immediately using the cabbage method AND pH strips, but no separation has been apparent.

The use of rice until I can get my mitts on a dehumidifier is a fantastic idea.

You guys are really amazing.

You’re welcome Melissa! 🙂

-Kelsey with Bramble Berry

I made a batch of cold processed soap that didn’t turn out as planned.

ie: air bubbles, over scented “a bit” and not happy with the color.

Can I grate it and use it as confetti is a new cold processed batch ?

I’d like to make a sandalwood batch and have the rose scented confetti through out the new batch. Is this possible or will the gelling process destroy the grated part?

Hi Fabienne!

You can definitely use the soap as confetti in a new batch! That is a great way to use leftover soap or soap that didn’t turn out like you planned. It works really well and the shreds hold up nicely in the new batch. 🙂

We did something similar in the Couture Confetti Cold Process Soap: https://www.soapqueen.com/bath-and-body-tutorials/couture-confetti-cold-process-soap/

Get more ideas for using leftover soap scraps in this post: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/use-leftover-soap-scraps/

-Kelsey with Bramble Berry

is it possible to save coconut oil that was mixed with something other than lye?

was told what I was buying was for Lye, but it wasn’t. when it cooled in the crockpot it separated from each other.

Can I melt the Coconut oil and strain out any of the debris? or is the oil completely ruined?

Hi Jennifer!

Do you know what the mixture was? My worry is that it may not be skin safe, or that it may be diluted lye. I would recommend pH testing the soap. You can see how to do that here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/test-ph-red-cabbage/

Even with a pH of 9-10 or lower, the coconut oil may not be safe or effective to use in another recipe. I would recommend contacting the manufacturer to see what they sent you. If it’s dangerous or caustic at all, you may need to toss the coconut oil.

-Kelsey with Bramble Berry

On one of the prettiest soaps I’ve ever made with an awesome drop swirl I ran into something I’ve never seen before. I noticed about a week or two after I cut the soap that it had little dried white somewhat crunchy specs on it. It honestly looks almost like lie that has been undissolved but when I looked online as to how to find out if said you put a speck on a paper towel and get it wet and if it did not turn brown then it wasn’t lie. I did the test it did not turn brown, but I can’t figure out what it is and if the soaps would be safe to sell. Has anyone ever ran into this and can you shed any light?

Hi Jessica!

I’m wondering if it may be soda ash! It can have an ashy, flaky appearance. Soda ash forms when unsaponified lye reacts with naturally occurring carbon dioxide in the air. The good news is it’s purely aesthetic and doesn’t affect the final bars. Even better news is that you can get rid of it! You can steam it off, or wipe it off with an old nylon.

Learn more about soda ash and how to prevent it here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/explaining-and-preventing-soda-ash/

-Kelsey with Bramble Berry

Hello, I just made my second batch of soap ever (formulated my own recipe with 60% hard oils etc) with coconut oil, olive oil, palm oil, cocoa butter, unrefined shea butter and castor oil. They seem to be hardening nicely in less than 24 hours, but at the bottom and on the sides of most of the molds I can see blotchy darker areas. On the orange colored soap it is darker orange, and on the black soap, it is darker black in irregular blotchy patches. I did make the mistake of adding a bit of fragrance (only 20 drops for a 50 oz batch) after reaching a medium trace (last time I wasn’t sure I reached trace, so I overcompensated this time). Is there an email I can use to send a photo? I just want to know what this is, and whether it is safe to use. It’s too blotchy to assume it is a patch of gelled soap. Thank you!

Hi Mei-Ling!

Hmm, it kind of sounds like the soap is going through gel phase! I’d love to see a picture to confirm though. Can you post that on our Facebook page? You can put it on the wall, or in a private message. 🙂

Bramble Berry Facebook: https://www.facebook.com/BrambleBerry/

If you don’t have a Facebook account, let me know and I can give you my email!

-Kelsey with Bramble Berry

Hii…

I am new into soap making.. I tried making some soaps using melt and pour technique. But I’m not satisfy with the final output… I’m facing so much of a problem of soap hardening… As soon as I’m removing my soap flakes from a microwave, it immediately gets hardened… So 1/3rd portion of my soap gets wasted… What shall I do for it??

Waiting for your reply… Thank you so much in advance!!

Hi Suvarna!

I’m sorry about that! I’m wondering if the melt and pour may be burnt. If melt and pour soap gets too hot, it can burn. That makes it gloppy, or form a skin, or harden really quickly. You can read more about burnt melt and pour here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-avoid-burnt-melt-pour/

To prevent the soap from burning, we recommend heating it on very short bursts – as short as 5 seconds. Then, stir well in between each burst. It also helps to adjust your microwave settings to low so it heats gently. 🙂

-Kelsey with Bramble Berry

I make cold process soap and I put it in the refrigerator for 12 hours. When I unmold my soap it gets a little oily on the bottom. I test the ph and it is good. Why is it oily and what can I do. My recipe is the lots of lather.

Thanks

Kathy

Hi Kathy!

Hmm, I’m wondering if it’s just a bit of condensation. When the soap moves from the cold refrigerator to room temperature, it can form beads of moisture. It’s similar to what happens when you take a cold drink out of the fridge! That moisture should evaporate as the soap cures. Do you notice it lasting longer than a couple of days? Thanks Kathy. 🙂

-Kelsey with Bramble Berry

Hello, need some help figuring out why my soap is soft at the bottom. I superfatted @5%. The oils were canola, rice bran, palm kernel grapeseed and green tea butter. Additives were colloidal oatmeal and bentonite clay. Batch was separated and activated charcoal and lavender, rosemary and tea tree essential oils added to one, the other had orange peel powder and tea tree essential to added. Both were poured into the 12 cavity silicone mold and insulated. It is now day 3 since the soap was made and while the top of the soap is hard and set, when trying to unfold I am seeing where at the bottom it sticking to the mold. I have placed it overnight in the fridge in an effort for it to harden but the result is the same. What can I do in order for the bottom is the soap to be as hard and set as the top?

Thanks

Hi Ariane!

That’s actually a normal process! When the soap is poured into the mold, everything but the top is cut off from the air. Because of that, the soap on the bottom will be a bit more soft than the top at first. The top is exposed to air right away, giving it time to harden. That is especially the case with recipes with more soft oils.

As your soap cures, the bottom of the soap will start to firm up! After 4-6 weeks, the entire bar should be firm to the touch. 🙂

To help the soap harden and unmold faster, you can add 1 tsp. of sodium lactate per pound of oils to your cooled lye water. Read more about sodium lactate here: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-sodium-lactate/

You can also water discount your soap! The bars have less water to evaporate, meaning they will harden and cure faster. Read more about how to water discount here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/water-discounting-cold-process-soap-how-why/

-Kelsey with Bramble Berry

Thanks very much for responding.

You’re welcome! 🙂

the strangest thing keeps happening to my soaps when I use titanium dioxide. When I cut the soap small white streaks appear on some of the bars I cut. It looks like dried T.D, but I’m not sure how to prevent this. I also am having a horrible time with T.D- my soaps never come out white. How much should I be using per pound of soap?

Hi Lisa!

That can definitely happen with titanium dioxide! Because it is a larger particle, it can leave little clumps of color in the soap. To prevent that, we like to micronize it. To micronize the colorant, simply use a coffee grinder to blend it and break up any clumps of color and prevent streaks of white from showing in the final soap. We like to use a coffee grinder that has a removable, stainless steel mixing area for easy cleaning.

As for how much titanium dioxide is needed in soap, it depends a bit on your batter! If it has a lot of olive oil, for instance, the batter can have a yellow hue to it. We recommend using whiter oils like coconut, palm and canola oil. Then, you can mix 1 teaspoon of titanium dioxide to 1 tablespoon of a lightweight oil, like sweet almond oil. If you’re making a larger batch, you may need to mix 2 teaspoons of the colorant into 2 tablespoons of oil, or 3 teaspoons into 3 tablespoons. Then, add the dispersed colorant 1 teaspoon at a time until you get a nice white color.

Learn more about getting vibrant colors in soap here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-get-vibrant-colors-in-soap/

And learn more about titanium dioxide here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/sunday-night-spotlight-titanium-dioxide/

-Kelsey with Bramble Berry

Hi guys, i am new to soap making but interested at this point in liquid soaps of different kinds. I made some Castile (with glycerin) 2 month’s back and it has been great – used a little coconut 72 so it had some mild sudsing. Came out good, not perfectly clear etc but has been a great first start for me. I did not know about the zap test or about being lye heavy although this one seems good doing the zap test. However, i just made a 100% virgin coconut liquid soap and i think i mucked up the lye amount because the initial recipe called for 50% fractionated and i used 100% Virgin. It seems i was about 20 grams too high on the KOH over 450grams of Virgin Coconut. So with this i have cooked it longer and the translucent stage came about after about 3 1/2 hours with some liquid deposits which i was sure if it was water or what. Didn’t feel like water. Needless to say, i saved the soap paste, cooled it and did a zap test which shows up an tiny tiny zap if anything. When i use it diluted i find it is milky in water so the recipe kind of failed in that area. However, it cleans and suds well with a strong clean smell. I wanted it for dishwashing liquid and laundry detergent. Can i use it this way? And do i need to use some citric acid for this when i dilute the paste which i see people talk about – i can’t quite work out what i should be doing with this batch or whether i should toss it. I don’t mind it being a white liquid soap, if it can be used.

PS, love this site! I have a lot to learn 🙂

Dean

Hi Dean!

Oh darn, I’m sorry about that! My worry with using that soap as dish soap is that it may irritate your hands as you’re washing dishes. To be on the safe side, I wouldn’t recommend it for dish soap.

You may be able to use it as laundry detergent though! We often use lye heavy cold process soap as laundry soap, so liquid soap should be similar. I would recommend testing a small amount on your clothing to see what you think. 🙂

Also, Amanda with Lovin’ Soap has an awesome blog post that talks about how to neutralize liquid soap using citric acid. I think that will be helpful! You can find that post here: http://www.lovinsoap.com/2010/09/liquid-soap-neutralizing-and-superfating/

-Kelsey with Bramble Berry

Thanks Kelsey, it is all learning! Appreciate you taking time to reply to me and thanks for the advice and link 🙂

Dean

You’re welcome Dean! Happy to help. 🙂

-Kelsey with Bramble Berry

Hello

You’re tutorials was very helpful for me thank you very much 🙂

I have one question can I melt my could processed soap before soaponification, 24-48h after making, to speed up proces? Thank you again

Hi Bojana!

You can use a hot process method to speed up the saponification! Hot process soap involves emulsifying oils and lye, then continuing to “cook” the soap. That helps it saponify more quickly. Learn how to make hot process soap in this video: http://www.soapqueen.com/bath-and-body-tutorials/lavender-lemongrass-hot-process-soap-on-soap-queen-tv/

This blog post has some great information on hot processing soap as well: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/hot-process-series-crock-pot-camo/

-Kelsey with Bramble Berry

HELP! I have a big mess on my hands. I have only made about five small batches and each one has been its own learning event. But this last one is really a mess. First I used a whole bag of quick mix to try a bigger batch of soap. It was a beautiful yellow at trace. I added one ounce of Cranberry Chutney and one ounce of Dark Chocolate fragrence. Within 30 minutes it was at GEL phase all the way through and had turned a dark cardboard brown. It had two shallow cracks on top. I kept it covered but with less insulation. 18 hours later still very dark colored and translucent. Will let it set for a few days. But what happened? The color is bad and I never expected that much heat. I followed the lye calculator. I think the fragrances likely caused the color. But why so fast on gel? I loved the beautiful yellow and the lovely texture so am really sad I ruined that!

Hi Sherry!

Your soap is turning brown because of fragrance discoloration. The Dark Rich Chocolate Fragrance Oil has 15.9% vanilla content. Fragrances that contain vanilla will discolor your soap various shades of brown. You can read more about fragrance discoloration in this post: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/why-did-my-soap-turn-brown/

The good news is the soap is still totally fine to use! It will be a lovely warm brown color, and will smell really great.

For your next batch, if you want to keep the soap a nice yellow color, you can use a non-discoloring fragrance. You can find our clear and vanilla-free fragrances here: https://www.brambleberry.com/Clear-Vanilla-Free-C491.aspx

Each description on Bramble Berry will say if the scent discolors, so make sure to check those out. 🙂

As for why the soap gelled, it sounds like it got a bit hot! If you soaped at higher temperatures and your house is on the warmer side, it may go through gel phase, even without insulation. If you notice your soap is really hot, you can leave it at room temperature uncovered, or even pop it in the fridge or freezer to keep it cool.

Learn about what factors affect gel phase, and when to insulate your soap in this post: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/when-to-insulate-handmade-soap/

-Kelsey with Bramble Berry

Dark Rich Chocolate Fragrance Oil: https://www.brambleberry.com/Dark-Rich-Chocolate-Fragrance-Oil-P3881.aspx

Cranberry Chutney Fragrance Oil: https://www.brambleberry.com/Cranberry-Chutney-Fragrance-Oil-P5430.aspx

I just made a few soaps and when I unmolded them they were oily. The recipe has been one I’ve been using for a least a year now.

I made two soaps with fragrance oil, one with essential oil and a oatmeal soap. Oatmeal soap came out just fine. The fragrance and eo soaps are oily. What could make it change up like that? I’m always careful to formulate the correct amounts. Please note that the weather has been crazy lately but like I said the Oatmeal one did not have the oily residue and is drying up. The orange essential soap is beginning to dry. Is there a quicker way to dry these bars? Who it be a good idea to just place them in the oven and let them sit?

Any help would be appreciated.

Thank you!

Hi Alicia!

Hmm, that’s strange! I wonder if those bars are separating. That can happen if the mixture isn’t mixed fully, or gets really really hot.

Can you tell me a bit more about your recipe, including ingredients, the temperatures you soaped at, how long you stick blended for and how you stored the soap? That way I can help you troubleshoot, and what to do with the soap now. 🙂

-Kelsey with Bramble Berry

I recently made two different batches of soap using the lye calculator on thesage.com. I used 5% lye and they both crumbled when I cut them. I’m not sure what I am doing wrong. Could the knife be affecting it?

Hi Misty!

Oh no, I’m sorry about that! Several factors can cause crumbly soap, including sodium lactate. If a bit too much is used, it can make that soap crumbly. Also, if the soap got really hot, it can also crumble. We recently made a soap with honey that got so hot it crumbled when we cut it. You can see that soap here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/adding-honey-to-cold-process-soap-tips-tricks-recipe/

Can you tell me a bit more about your recipe, including ingredients, temperature, and any additives? Let me know and we’ll get this figured out. 🙂

-Kelsey with Bramble Berry

I made a cold process with a recipe I use all the time. It was very strange that during blending, it never got to trace. I poured it anyway. 24 hours later, the top is covered in a good amount of oil and the center appears to still be soft. What do I do?

Did it ever harden all the way through? I made soap yesterday and the same thing happened. I stuck a toothpick in it and the center seems to be hardening but the top layer is still very liquid.

Hi Kelly and Sarah!

I must have missed this comment. I am so sorry for the long wait!

Soaps with a lot of soft oils can take awhile to thicken and get to trace. However, as long as there are no streaks of oil, the batter should be emulsified.

Also, most soaps stay in the mold for at least 3-5 days before they’re ready to unmold. I would recommend letting that soap sit at least 5 days, then checking again. By that time, it should firm up nicely. 🙂

To help your soap unmold faster, you can add 1 teaspoon of sodium lactate per pound of oils to your cooled lye water. Read more about sodium lactate here: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-sodium-lactate/

-Kelsey with Bramble Berry

Hi,

I was making a 2lb batch of soap and and tried to use sodium lactate to harden bars of soap. I added to lye water solution and when oil and lye were to 110 I mixed and batter siezed terribly. I retried with different fragrance with same results. This is my standard recipe so I think it is sodium lactate 60%. I used 2 tsp. What am I doing wrong??? I have a whole pound of this stuff and im wasting fragrance oils and oils 🙁

Hi Lizette!

Oh no, I’m sorry about that! Typically, sodium lactate shouldn’t cause that batch to seize. It soaps beautifully!

Do you know if there is an additive in the sodium lactate you’re using? For instance, if it has alcohol, that could be what’s happening. Alcohol tends to seize batches up fairly quick. Can you tell me a bit more about your recipe as well? Let me know and we’ll get this figured out. 🙂

-Kelsey with Bramble Berry

Hello!

I have just made some goat’s milk melt and pour soaps with English rose fragrance oil, and I used 1 drop of red food colouring (I use it all the time as colourant) I also put a rose bud on top. They look great now, but something weird happened when I was about to pour it. It turned very thick, as thick as thick trace in cold process. I microwaved it again but that just made it form a thick skin on top. I just removed the skin and managed to glop it into the mould.

Any ideas about what happened? I know I didn’t burn it because I was using 10 second bursts.

-Cadence

Hi Cadence!

Hmm, it sounds like it’s behaving like burnt melt and pour soap, even though you were using very short bursts! Burnt melt and pour hardens up very quickly and forms a skin on top. You can see an example of that here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-avoid-burnt-melt-pour/

It may help to microwave on even shorter bursts, like 5 seconds, or to reduce your microwave setting to low. You can also add up to 5% glycerin or distilled water to help rehydrate the soap.

🙂

Liquid glycerin: https://www.brambleberry.com/Glycerin-Liquid-P5965.aspx

-Kelsey with Bramble Berry

I made a soap with essential oils and no colorants, however, while cutting it just crumbled. What else I could with this soap? Use it for laundry soap or reuse in another soap? Thanks.

Hi Yolande!

You can definitely use that for laundry soap if you like! Learn how to make that here: http://www.soapqueen.com/bath-and-body-tutorials/home-crafts/three-diy-laundry-soap-recipes/

I’m wondering why that soap crumbled on you! Would you mind telling me about your recipe? Also, how long did it sit in the mold before you cut it? Did you use any sodium lactate? Let me know and we’ll get this figured out. 🙂

-Kelsey with Bramble Berry

I’ve had problems before with glycerin rivers and cracking and that was when I was soaping around 115 degrees. Last night I was sure to soap around 75/80 degrees especially since I was using titanium dioxide. I was so excited for this batch so I took a peek this morning and was extremely disappointed that there is STILL cracking on the top. I’m not sure it is fixable since I sprinkled mica on the top.. I’m terrified to unmold and because I don’t want to find glycerin rivers!

Hi Chelsea!

Oh no, I’m sorry to hear that! To help prevent glycerin rivers, you can pop your soap in the freezer after it’s in the mold. That will prevent it from getting too hot.

It also helps to water discount that soap by 10% or so. 🙂

-Kelsey with Bramble Berry

Hello!

My soap has been getting hard bubbles that look like tiny beads all over it. They are only visible on the areas where I cut my soap but it makes them look and feel rough. Do you know what could cause them?

Thank you! 🙂

Hi Valeria!

I’m wondering if those are air bubbles! They can sometimes look like little white beads in your soap.

It can also be the palm oil or butters in your recipe. If they aren’t fully melted, they can start to harden before they’re fully saponified, leaving little bits in your soap. Can you tell me a bit more about your recipe, and how hot you’re soaping? Thanks!

-Kelsey with Bramble Berry

Today I ran into a problem that might be specific to hot process – my soap was too cool by the time I was putting it in the mold. I waited as long as I could to avoid losing my orange valencia EO (my soap was about 160 degrees F when I started to add color/EOs), and I even used a saltwater mix acting as sodium lactate (I think it really did help), but my end product has a lumpy, uneven surface indicative of partial cooling as it was going in the mold. Lesson learned – low flashpoint EOs should be saved for CP – but what are my options for my lumpy, ugly mini-loaf of orange anise? Half of it will fall apart if not handled carefully.

If I rebatch, won’t I lose that orange scent I wanted in the first place?

Hi Katenik!

Oh no! I’ve definitely had that happen to me – hot process does harden more quickly than cold process soap.

You can definitely rebatch the soap if you like. Because Orange Valencia Essential Oil has a low flashpoint, some of that scent may fade during the rebatching process. You may like our 10X Orange Essential Oil. It has a higher flashpoint and is super concentrated, so it lasts well in cold and hot process soap.

10x Orange Essential Oil: https://www.brambleberry.com/10x-Orange-Essential-Oil-P4441.aspx

You can use our Fragrance Calculator to find out how much to add. Because your batch already has essential oil in it, we recommend not adding too much extra essential oil. That can cause potential skin irritation.

Fragrance Calculator: https://www.brambleberry.com/Pages/Fragrance-Calculator.aspx

-Kelsey with Bramble Berry

I find that using 99% alcohol vs. the 92% makes a big difference in reducing or eliminating soda ash. I insulate and gel practically everything, and the key is to avoid contact with the air. I use plastic wrap over my mold after spraying then cover it up, and spray 99% alcohol a few times during the first 2 hours. I might still get a small amount of soda ash here and there on some occasions but overall I never see it anymore, even when using recipes or fragrances that I know cause it more than others. Fortunately, I have never experienced DOS or air bubbles in my soap.

Hi Michael!

We have found that as well! We use 99% isopropyl alcohol all the time in the Soap Lab.

Sunday Night Spotlight: 99% Isopropyl Alcohol: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-99-isopropyl-alcohol/

Also, thanks so much for your awesome tips! It sounds like you’ve found a great way to prevent pesky soda ash. 🙂

-Kelsey with Bramble Berry

Glycerin Dew (aka: Sweating) This problem is unique to melt and pour soap.

I am not sure I agree with the above. I have been meaning to mail for a while and ask why my CP soap sweats. I live in a fairly humid part of South Africa and wondered if this was the reason? If not could it be the recipe and hence the creation of glycerine when the acids and alkali combine?

Hi Odette!

Sweating in cold process soap can occur as well! The usual culprits are salt, fragrance oils or extreme temperature changes. For instance, if the oils and lye water are fairly hot and then the soap is put into the refrigerator. When it comes out of the fridge, it can start to sweat. That sweat should start to disappear in a couple of days at room temperature.

If you tell me a bit more about your recipe I’d be happy to help you troubleshoot! 🙂

-Kelsey with Bramble Berry

Dear Soapqueen,

I am experimenting with gel phase lately. I pour the soup in the mold and put it in the oven for an even warming. I have tried putting the oven on different temperatures (65-80 degrees Celsius). My soap does not seem to be boiling, but I have many tiny airbubbles in the soap after cooling down. Is this normal or am I doing something wrong? The soap from the same batch that has not been in the oven does not have any bubbles (and did not go through gel phase).

With kind regards,

Annemieke

Hi Annemieke!

It sounds like the soap may have air bubbles that are floating to the surface in the oven and popping. Before putting your soap in the oven, give it several good taps on your counter. That should help pop those air bubbles before your soap goes in the oven.

It also helps to pour your lye water down the shaft of your stick blender, and to burp your stick blender before turning it on. 🙂

-Kelsey with Bramble Berry

What causes soap warts? LOL! Seriously, I don’t know what else to call the little bumps that sometimes pollute cut CP bars. I’ve been wondering if it’s something to do with colorants because some seem to behave worse than others. I’ll cut a loaf of soap and each bar is nice and smooth, but a day or two later, swirls develop ridged outlines where different colors meet up with one another, or one color within the bar suddenly looks like it has acne while the rest is smooth. It doesn’t happen often, but it’s maddening when it does, particularly because I can’t nail down the cause.

Hi Jennifer!

I’d love to help you out! Can you tell me a bit more about your recipe, including the colorants you’re using?

Also, are the bumps white? Or, are they the same color as your soap? How big are they?

Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry