One of the questions we get asked all the time is, “Can I put cold process soap in your plastic molds?” The answer is yes, absolutely! However, the unmolding process is a little different compared to cold process in wood molds and silicone molds. The plastic molds are airtight. While your cold process soap is in the mold, no air is touching the soap inside. That means the soap has to stay in the mold longer. Never fear! There are several tricks to getting your soap out of the mold with all the beautiful details intact.

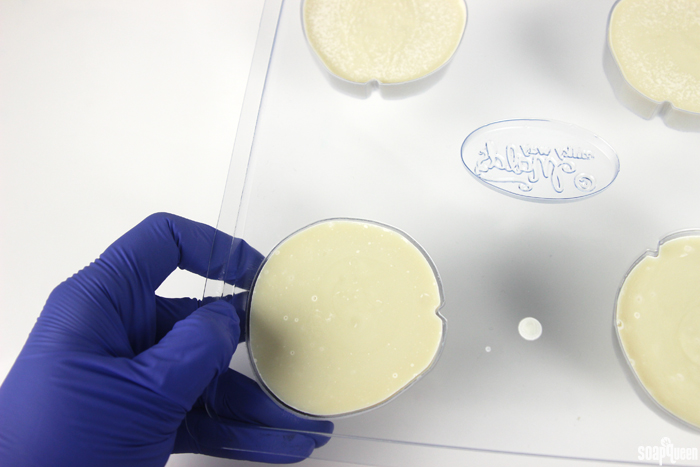

First and foremost, patience is key. While soap in silicone or wood molds is ready to unmold as early as 3-4 days, cold process soap in plastic molds can take up to 2 weeks. If your soap is still soft when you try to unmold it, it can leave drag marks or holes. Some of the details may be left in the mold as well. So, if your soap doesn’t want to come out of the mold, let it sit for another day or two.

The recipe you use plays a huge role in determining how long the soap needs to stay in the plastic mold. Soap with a lot soft oils – oils that are liquid at room temperature – takes longer to harden. Soap with mostly soft oils, like olive oil and sweet almond oil, can take even longer than 2 weeks to unmold. Also, some of the details may not be as clear. Recipes with a lot of hard oils – oils that are solid at room temperature – will pop out of the molds faster. Hard oils include coconut oil, palm oil, cocoa butter and shea butter. Read more about hard and soft oils in the Formulating Cold Process Recipes post.

Sodium lactate is incredibly helpful when unmolding cold process soap from plastic molds. Sodium lactate is the sodium salt of lactic acid. Adding 1 tsp. of sodium lactate per pound of oils to your cooled lye water speeds up the unmolding process. It also produces harder, longer-lasting bars of soap. I use it every time I make cold process soap in plastic molds. To learn more, click through the Sunday Night Spotlight: Sodium Lactate.

You’ve made a recipe with mostly hard oils. It’s been in the mold for at least a week, and it has sodium lactate. What now? To unmold, pull on the sides of the mold. This breaks the airlock. Then, flip the soap mold over and press gently on the back of the cavities with your thumb or the heel of your hand. If the soap doesn’t want to come out, pop it in the freezer for about 10-15 minutes. Don’t leave it in there too long, or the plastic can crack. If the soap still isn’t budging, let it sit in the mold another couple of days. Remember, patience is key!

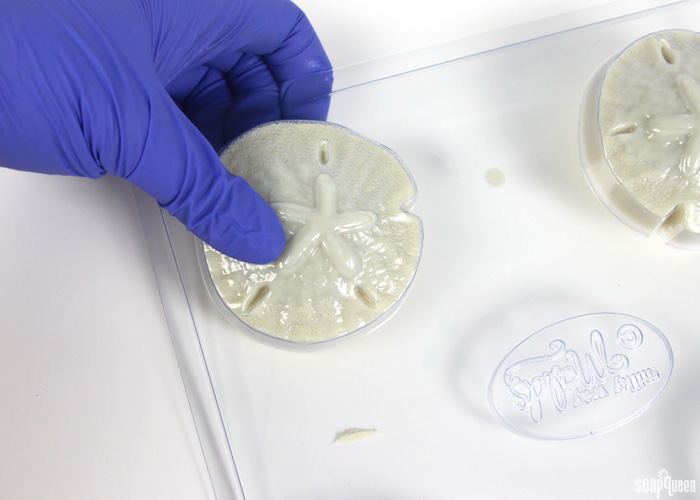

To demonstrate how different recipes perform, two cold process recipes were made in the Sand Dollar Mold. One of the recipes consisted of 70% soft oils, and the other recipe consisted of 70% hard oils. We then tested the same two recipes, but the second time we added 1/4 tsp. of sodium lactate to the lye water.

Soft Oils Recipe

.5 oz. Coconut Oil (15%)

2.5 oz. Olive Oil (70%)

.5 oz. Palm Oil (15%)

.5 oz. Sodium Hydroxide Lye

1.2 oz. distilled water

Optional: 1/4 tsp. Sodium Lactate

Hard Oils Recipe

1 oz. Coconut Oil (30%)

1 oz. Olive Oil (30%)

1.4 oz. Palm Oil (40%)

.5 oz. Sodium Hydroxide Lye

1.2 oz. distilled water

Optional: 1/4 tsp. Sodium Lactate

Soft Oil Recipe

When unmolding the soap made with sodium lactate (shown on the left), they actually fell out of the mold! The soap is nice and firm, and all the details stayed on the soap. The soap on the right, without sodium lactate, didn’t fare as well. As you can see, several of the details are missing from the soap. There are also drag marks and holes.

Hard Oil Recipe

Again, the soap made with sodium lactate (shown on the left) fell out of the mold. It is firm and beautifully detailed. While the soap without sodium lactate did a little better than the recipe with mostly soft oils, there are still holes. One of the soaps is also missing a part of the sand dollar.

Experiment Results

The main takeaway from this experiment is sodium lactate is your friend when it comes to making soap in the plastic molds. With sodium lactate, both the hard and soft recipes came out of the mold easily after one week. The soft oil recipe without sodium lactate performed the worst – the most soap stuck to the mold and the design was extremely damaged. Soap made with hard oils and no sodium lactate did a little better, but the design was still damaged. If you choose not to use sodium lactate and want to use a plastic mold, be prepared to wait more than one week to successfully unmold your soap.

If you don’t have sodium lactate, you can use a salt water solution to harden your soap. To make the solution, mix 1 teaspoon of regular table salt into 1 ounce (by weight) of warm distilled water. Stir until the salt is fully dissolved. We recommend 1 teaspoon of salt in 1 ounce of water per pound of soap. Make sure to discount the salt water solution from your liquid amount. Then, add the solution at trace. The salt water solution was used in the Palm Free Vertical Twist Tutorial with great results.

We don’t recommend using any of our clear plastic molds for hot process soap. They can only withstand temperatures up to 145° F. Hotter temperatures can morph the plastic. The heavy duty molds can withstand temperatures up to 165° F, but may warp in the oven. The heavy duty molds work for rebatch, as seen in the How to Make Rebatch Soap video on Soap Queen TV. Because the molds are heat sensitive, we do not recommend gelling cold process soap in them. Instead, you can let your soap dry at room temperature.

Don’t feel like waiting? Melt and pour soap is a great option! It is ready to unmold a couple hours in the mold, or up to 12 hours. Check out these melt and pour recipes made with plastic molds:

Top row, left to right: Mermaid Shell Melt and Pour, Movember Mustache Melt and Pour

Bottom row, left to right: Painting Soap with Mica Powder on Soap Queen TV, Rainbow Unicorn Melt and Pour

Do you use plastic molds for cold process soap? Do you have any tips for unmolding? I’d love to hear them!

Put them in the freezer for an hour, they pop right out.

The freezer can definitely help! Don’t leave the mold in there too long otherwise the mold can crack. It does help the soap slide out easily though. 🙂

-Kelsey with Bramble Berry

Hi,

I am new to soaping and have only made a few batches. I have goats and I have used the recipes for goats milk. I did notice that my soap in the plastic molds I got from Brambleberry did not come out clear in details. I thought maybe that was how it is suppose to be since I am new and I was disappointed as my bees really didn’t stand out. I bought Sodium Lactate when I bought my supplies but have not figured out how to use it. Most information is about regular soap not milk. Can you please help me with this as I am ready to make more and I really want the details to shine!

Thanks for sharing your knowledge! I have learned so much from your blogs and videos! I think soaping could become very addicting!

oh and when I see recipes for coconut milk is that usually the coconut milk in a can from say Trader Joe’s or is it the rectangular box coconut milk?

Ok one more thing- do you have a tutorial on how to use the soap calculator lye calculator or whatever it is called. For some reason it intimidated me and seems complicated and I think it is important for me to learn how to use it!

thanks!

Kris

Hi Kris!

You can use sodium lactate with milk soap as well! We recommend adding 1 teaspoon of sodium lactate per pound of oils to your cooled lye milk. Also, because milk adds extra fat to your soap, it may need a few more days to unmold. I would recommend adding sodium lactate and waiting a full week before trying to unmold. If you find it’s still soft after then, give it another couple days and try again. 🙂

You can use whatever coconut milk you find! We’ve found the coconut oil in the box works well because it’s a bit thinner.

Also, we do have a post on how to use the Lye Calculator! Find that here: https://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/using-the-bramble-berry-lye-calculator-2/

We have updated our website since then so the calculator looks a bit different. However, it still works the same! 🙂

-Kelsey with Bramble Berry

Hello (:

If you’re using silicone molds, is it okay to pop your CP soap in the freezer for a few hours before removing it from the mold? Do the cold temperatures in any way negatively affect the soap?

Also, can you use frozen juice cans as soap molds? The cardboard ones. Like: http://i5.walmartimages.com/dfw/dce07b8c-c89f/k2-_4577da00-b60c-49ec-8b71-eb2ac617cb3f.v1.jpg

Thank you (:

Hi Daniel!

You can definitely pop your soap into the freezer! There are some recipes where we recommend that. For instance, if the soap is made with milk, we recommend putting it in the freezer for 5-24 hours. That way the milk won’t get too hot and scorch, which can cause discoloration and an unpleasant smell. Read more about working with milk in soap here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-add-lye-to-milk-for-cold-process-soap/

After the soap comes out of the freezer, we recommend letting it sit at room temperature for 3-5 days before unmolding. Putting the soap in the freezer slows down the saponification process slightly, but the soap complete that process as it sits at room temperature.

Whether you freeze your soap or force gel phase is definitely personal preference. This post has great tips on when to insulate and when to cool the soap: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/when-to-insulate-handmade-soap/

As for the frozen juice cans, we don’t recommend using those. They may use aluminum, which reacts with the lye to create toxic fumes. You can use a variety of other recycled molds though! We’ve used cardboard boxes, milk cartons, plastic food containers, etc. Read more about using recycled molds here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/back-to-basics-how-to-choose-a-soap-mold/

-Kelsey with Bramble Berry

If you leave the soap in the freezer for 5-24 hours wont it be frozen solid? Why wouldn’t you be able to unmold it right away? Will it… Turn into mush or something when it starts to thaw?

And for the cans couldn’t I cut circles out of freezer paper and set them at the bottom? I could mist the bottom with some type of oil so a tight seal is created between the freezer paper and the aluminum… But there’s still a chance the soap would leak along the edges. I looked at your silicone pillar mold, but in a tutorial in which you use it you get a line down the soap where the two halves connect. Any way to avoid that?

Thank you (:

Popping the soap in the freezer will make it harder, but it’s not fully saponified yet. That means as it sits at room temperature it can soften again. If it’s unmolded, it may not hold its shape. After the freezer, we recommend letting it sit at room temperature for 5-24 hours to make sure it sets up fully!

I really wouldn’t recommend using any container with aluminum. Even if the aluminum is wrapped, if the soap comes in contact with it by accident it can create those dangerous fumes. There are lots of other recycled containers you can use though! For a circular shape, you can use PVC pipe. We did that in the Neon Embed Cold Process Soap video: https://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/neon-embed-cold-process-soap-video-tbt/

For the Silicone Column Mold, there may be a bit of soap that leaks out of the side. It is easy to remove though! You can use a butter knife or this handy dandy clean up tool: https://www.brambleberry.com/Clean-Up-Tool-P4758.aspx

See how to use that mold in the Faux Funnel Pour Video: https://www.youtube.com/watch?v=68lEcuuYYEc

-Kelsey with Bramble Berry

Silicone Column Mold: https://www.brambleberry.com/Silicone-Column-Mold-P5619.aspx

Thank you so much for all your help Kelsey! I really appreciate it (:

You’re welcome! Happy to help. 🙂

-Kelsey with Bramble Berry

This might have been said already but wiping or spraying the molds with mineral oil is a total game changer. I haven’t used the small plastic molds but I always had issues with silicone molds for the same reason (no air). I wipe out my silicone molds with mineral oil, concentrating on corners. I also find it helps to add 1 teaspoon salt PPO to the water before adding the lye and use .5% stearic acid mixed into the oils. Soap is ready to unmold and cut in less than 24 hours.

Thanks so much for the great tips Mokhe! Mineral oil or cyclomethicone can definitely help the soap slide out easily. Hardening with salt and stearic acid helps too! 🙂

-Kelsey with Bramble Berry

Cyclomethicone: https://www.brambleberry.com/Cyclomethicone-P4560.aspx

Stearic acid: https://www.brambleberry.com/Stearic-Acid-by-weight-P4210.aspx

This seems so complicated. I am not ready for all that even though I want to try it next time, I have a question. I have used bought soap and used for melting my ordinary cooking pot. Is that ok to use the pot for cooking again? I read you are not suppose to use your stuff that is used for cooking.. What can I do to make it right. What kind of wash do I have to do to decontaminate it .

Hi Blanca!

There are a few extra steps to take with cold process soap in plastic molds, but it will help that soap unmold smoothly! If you like, you can also use silicone molds. They are nice and flexible, so the soap unmolds easily. Read more about choosing a soap mold here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/back-to-basics-how-to-choose-a-soap-mold/

As for your soaping equipment, we recommend keeping that separate from utensils used for food. Even with a really thorough washing, fragrance oil or bits of soap can get into micro cracks and chips in the pot. That means you can accidentally ingest them next time you make food. To be on the safe side, we recommend having a different set of pots and utensils for soap and for food. 🙂

-Kelsey with Bramble Berry

If sodium lactate can be added to lye water solution, why can’t sodium chloride solution be added to lye water? why did you suggest to add the latter at Trace?

Hi there!

We’ve had the best luck adding sodium lactate in the lye water. We’ve found it mixes in easily and doesn’t accelerate trace. However, the salt water solution can accelerate slightly. That’s why we suggest adding it at trace – it gives you a bit more time to work. 🙂

-Kelsey with Bramble Berry

Hello 🙂

I was wondering if the aluminium candle tins can be used as a mold for CP soap? I know the aluminium and lye dont like each other, but im not sure if raw soap is ok? I would like to make shaving soap, and pour it into the candle tin and leave it like that. Without taking the soap out at all. And if it is possible would the curing time be longer since the soap has no air?

Thank you 🙂

Hi Natasa!

We definitely don’t recommend using aluminum as a soap mold. Aluminum reacts with the lye in the soap and creates toxic fumes. Definitely avoid all aluminum when it comes to soapmaking!

Also, we recommend removing the soap from the mold so it can cure. Curing creates a harder, milder bar that lasts longer in the shower. 🙂 Read more in the How to Store Handmade Bath Products post: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-store-handmade-bath-products/

-Kelsey with Bramble Berry

Hi! I wish I had read about molds before pouring my soap into an aluminum mold. My bad. Luckily, I was still able to rescue my soap and transfer to a silicone one. My question is, can I still use this soap after curing? Or would it have created toxic stuff due to the reaction of lye with the metal that it should no longer be used? Thanks in advance!

Hi Amanda!

I’m not entirely sure if that soap is OK to use. The toxic fumes are created when aluminum reacts with fresh lye. Because your recipe no longer has fresh lye in it, it should technically be fine to use. However, I’d hate for any other reactions to happen, especially on your skin. To be 100% safe, I would recommend not using that batch.

-Kelsey with Bramble Berry

Totally agree on safety. Thank you!

You’re welcome!

I work in grams , so if I made a 1000 gram batch of soap how much sodium lactate could I add into the lye as I am not sure. I have a beautiful teddy bear mold and have only tried two attempts to get the soap out of the mold and lost a leg and arm of the teddy . If sodium lactate can make the soap release from the mold I will be so happy to get a full teddy from the mold. Thanks

Kind regards

Deborah

Hi Deborah!

You can use the sodium lactate at .5-4% of your recipe. That should help those teddy bears unmold easily and with all the details intact. 🙂

Sodium lactate: https://www.brambleberry.com/Sodium-Lactate-P5127.aspx

-Kelsey with Bramble Berry

Hi, could you please do a post or video on removing CP soap from your 18-bar silicone mold and dividers? How long does it usually take?

I just unmolded soap that was in there for 3 days, but it was still a bit soft. Thanks.

Hi Martina!

Thanks so much for your suggestion! That’s a great idea. 🙂

It can take up to a week before the soap is ready to unmold from the wood molds, especially if you’re using the silicone liner. The silicone liner creates an airtight seal around the soap. That keeps air from getting in and drying the soap out.

Adding 1 tsp. of sodium lactate per pound of oils to your cooled lye water helps the soap release from the mold more quickly. Read more in the Sunday Night Spotlight: Sodium Lactate: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-sodium-lactate/

Adding more hard oils, like palm and coconut, can help that soap release faster as well. 🙂

-Kelsey with Bramble Berry

Birchwood molds: https://www.brambleberry.com/Search.aspx?k=birchwood+mold

I always melt about 1 tsp. of beeswax per pound of oils with my CP recipes going into plastic mols. I use the little pastilles so they’re easy to measure in tiny amounts. I find that once the oils are melted (yes, you have to go a bit hotter than usual to get the wax melted), it can cool quite a bit without the wax solidifying. I have no issues with acceleration, and pretty much soap at normal temperatures. This has made a world of difference for me. I also use sodium lactate, but I still had trouble with unmolding. A touch of wax plus sodium lactate works like a dream. Since it’s such a tiny amount of wax, I don’t include it in the lye calculations. It’s just a little bonus.

Another thing to try if you have lotion-making supplies on hand. Mist the inside of the molds with cyclomethicone. It does not saponify, and it is inert and doesn’t react with anything. Once your soap unmolds, it simply evaporates. It doesn’t impact the soap’s appearance at all. It is the same stuff used in room sprays. It carries the scent, and then simply evaporates.

Hi Leanne!

Those are amazing tips, thank you so much for sharing! Cyclomethicone is a great way to help soap pop out of the mold easily. Mineral oil works well too. 🙂

Cyclomethicone: https://www.brambleberry.com/Cyclomethicone-P4560.aspx

-Kelsey with Bramble Berry

Thanks for this! My attempts at doing CP in these molds look gummy and a lot like your pictures so I gave it up and only used them for melt and pour. I am going to have to get some Sodium Lactate and try again 🙂

Hi Margaret!

You’re welcome! I had some issues with these molds too! Sodium lactate makes such a huge difference though. I can’t wait to make more cold process in plastic molds. 🙂

-Kelsey with Bramble Berry

Wow I JUST emailed BrambleBerry about this very thing two days ago! A blog post about it was way more than expected. Thank you! 🙂

I’m wondering if anyone sees a difference in detail when using these plastic molds between CP soap and MP soap? Do you feel like the MP soap has sharper detail or do you feel that you could get the same results with CP soap? I’m not willing to wait weeks and weeks for CP soap to harden if it’s not going to give me good detail. But if it does, then I’d say it’s worth it because I don’t like MP soap.

Hi Chelsea!

You’re welcome! So glad you like the post. 🙂

As long as your cold process soap is fully hardened and ready to unmold, those details will be nice and sharp. However, this does take a bit of waiting, typically at least a week.

Melt and pour unmolds a lot faster from the molds, and the details are sharp as well. It’s definitely personal preference if you choose melt and pour or cold process. Either way, the details look awesome. 🙂

-Kelsey with Bramble Berry

I guess an advanced soaper could probably add beeswax to their recipe and that would help!

Hi Kristie!

Absolutely! Beeswax is a great way to harden your cold process soap. It also gives the soap a little bit of shine. 🙂

Busy Beeswax Soap Tutorial: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/beeswax-spoon-plop/

-Kelsey with Bramble Berry

Interesting… the photos of the soaps with sodium lactate look whiter than those without… does sodium lactate make soap whiter?

I was wondering the same thing. I didn’t realize Sodium Lactate whitens soap.

Hi Catherine and Martina!

We noticed that too when they were unmolded! It looks like the soap is a bit whiter. Up close, it also looks like they may have a bit of soda ash because they weren’t insulated and cooled quickly.

Explaining and Preventing Soda Ash: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/explaining-and-preventing-soda-ash/

It’s hard to say for sure if soda ash will make your soap whiter. It depends on a number of factors, including your recipe, fragrance, etc. However, in this case, it looks like it did help whiten the soap up slightly! 🙂

-Kelsey with Bramble Berry

Thanks for the post. Looks like we have both been busy with these fantastic moulds.

https://soapinthecity.wordpress.com/2015/04/07/success-with-your-milky-way-moulds-part-1/

That’s awesome! Great minds. 🙂

-Kelsey with Bramble Berry

Susi, thanks for posting the link to your blog. I read a couple of posts and I love it! Very informative!! I’ll keep reading! 🙂

Find out some more about success with Milky Way moulds here at my blog posts created last week. Thanks Marie.

Hi Susi!

You’re welcome! Also, I can’t wait to read through your blog post. It looks very helpful and in depth. 🙂

-Kelsey with Bramble Berry

Hi

I have a few questions.

Would the salt solution change the soap PH level?

Salt attracts water. Does it in any way affects the soap?

Tq

Hi Nik!

The sodium lactate or salt solution doesn’t change the pH of the soap! Adding it helps the soap unmold faster. It also creates a harder, longer-lasting bar of soap. Besides that, it doesn’t change the properties of the soap at all. We absolutely love using sodium lactate in all our recipes! 🙂

-Kelsey with Bramble Berry

Sunday Night Spotlight: Sodium Lactate: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-sodium-lactate/

Dear Soapqueen,

Thanks for this post. I have tried to make a soap in your 3D molds more than once, with both hard and soft recipes but always ended up with a damaged soap. None of the advice from my local shopkeeper was helpfull. Once I even had to cut out the soap with a knife after waiting a month, of course the mold was destroyed in the process.

I recently purchased sodium lactate but did not dare to try it in my remaining molds yet. I also want to try the salt water solution.

With kind regards,

Annemieke

Hi Annemieke!

I think the sodium lactate or salt water will really help! In our experiment, the soap made with sodium lactate actually fell out of the mold. It didn’t even need to be pushed out. 🙂

-Kelsey with Bramble Berry