There are a wide variety of ingredients to customize handmade soap. Oils, colorants, additives and fragrances create a perfectly customized bar. Honey is a popular additive for cold process soap. It has various properties that make it appealing for skincare. In particular, honey is a natural humectant, which means it absorbs moisture from the air. Humectants are great for the skin, as they can help the skin retain moisture. Honey also contains antioxidants and natural sugars which can increase the lather of cold process soap.

While honey has some great benefits for soap and skincare, it can be tricky to work with. Adding honey to cold process soap means you are adding extra sugar. Sugar causes cold process soap to heat up. This also happens when using ingredients such as milk, fruit juices and purees, which also contain natural sugars. When soap heats up after poured into the mold, the soap goes through gel phase. ‘Gelling’ and ‘gel phasing’ in cold process soap refers to a part of the saponification (soapmaking) process where the soap gets warm and gelatinous – up to 180 degrees. Click here to read more about gel phase.

In many cases, gel phase is a good thing! It can result in brighter colors, and give the soap a shinier appearance. But when you’re working with a soap that contains extra sugar such as honey, you may want to avoid gel phase. The extra sugar can lead to an extremely hot gel phase. The hot gel phase can produce cracked soap and a kind of caramelization, which leads to a deep color within the soap. If this happens, the soap is still perfectly fine to use, but it may not be the color you want. In some cases, sugar combined with extreme heat can even lead to a soap volcano. Check out the volcano that occurred when I made soap using coconut milk.

In general, use about 1 teaspoon of honey per pound of soap. You can certainly use more, but keep in mind the more honey you use, the hotter your soap will get. Some soapers add their honey to the soap directly during trace. Others prefer to dilute the honey in a portion of the water in their recipe, and add this mixture at trace. If you’ve never worked with honey in cold process soap before, I recommend keeping your design very simple, as the honey can cause the soap to accelerate and thicken quickly. This can make swirl and complicated designs very difficult.

When working with honey in cold process soap, I recommend keeping temperatures cool. This will help prevent the soap from scorching and caramelizing the honey. Most soapers work with their lye and oils around 100-120° F. When adding honey to my recipe, I like to soap on the cooler side, around 100° F. The more honey you add to the soap, the cooler your soaping temperatures should be. Then, to help prevent the soap from going through gel phase, place the freshly poured soap immediately into the fridge or freezer for at least 3 hours, up to overnight. Sometimes the fridge is not cool enough to prevent gel phase, so a freezer is a better option.

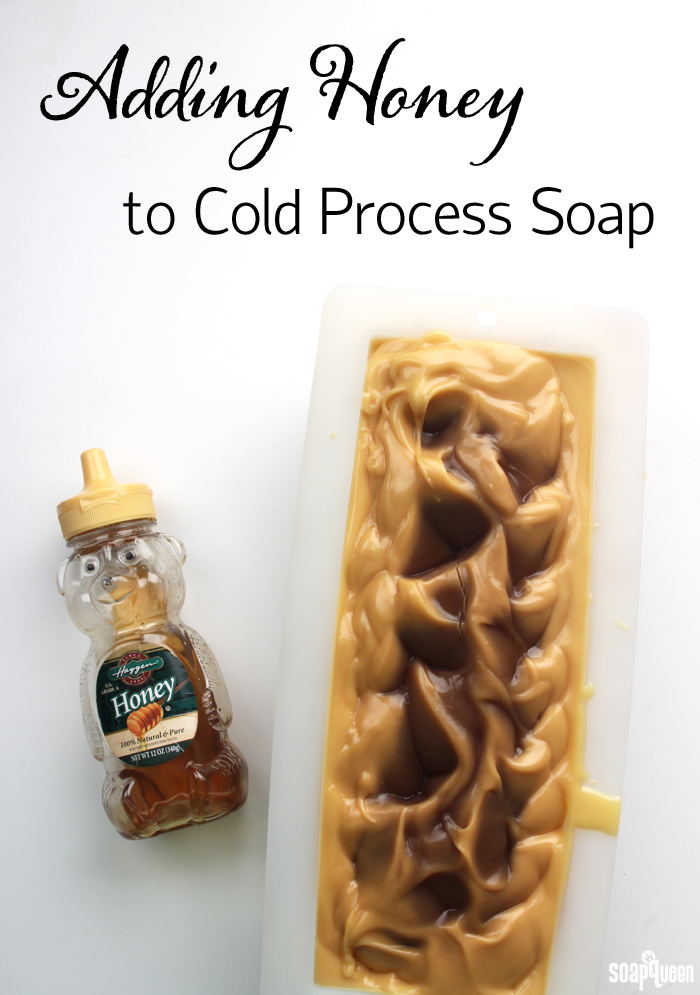

To demonstrate the effects of honey in cold process soap, I made a basic batch and split it into two molds. One mold went into the freezer, while the other soap stayed on the counter at room temperature. In order to really drive my point home, I used 2 teaspoons of honey per pound of cold process soap. This is more honey than I recommend. The large amount of honey in this soap caused it to really heat up! On the left is the soap left on the counter, while the soap on the right was placed in the freezer. The soap left at room temperature became extremely hot. The honey soap that went into the freezer also got quite warm, and went through a partial gel phase. Scroll down to see the process by which these bars were made, and more photos of the end results.

On the left, the soap was left at room temperature. On the right, the soap was placed in the freezer. Because so much honey was used, both soaps experienced gel phase!

On the left, the soap was left at room temperature. On the right, the soap was placed in the freezer. Because so much honey was used, both soaps experienced gel phase!

Honey Lemon Cold Process Soap

70 oz. Lots of Lather Quick Mix

10.1 oz. Sodium Hydroxide Lye

23.1 oz. Distilled Water

12 teaspoons of honey (about 2 teaspoons per pound of soap)

2 oz. Sweet Meyer Lemon Fragrance Oil

2 oz. Pure Honey Fragrance Oil

Fizzy Lemonade Colorant

Yellow Oxide

Note: The recipe below creates about 6.5 pounds of soap, which was poured into two 10″ Silicone Loaf Molds. If you’d like to replicate this recipe for one mold, use the Lye Calculator to resize the batch.

If you’ve never made Cold Process soap before, stop here! I highly recommend checking out our FREE four part SoapQueen.tv series on Cold Process Soapmaking, especially the episode on lye safety. And if you’d rather do some reading, Bramble Berry carries a wide range of books on the topic, including my newest book, Soap Crafting. You can also checkout the digital downloads for that instant gratification factor.

SAFETY FIRST: Suit up for safe handling practices! That means goggles, gloves and long sleeves. Make sure kids, pets, and other distractions and tripping hazards are out of the house or don’t have access to your soaping space. Always soap in a well-ventilated area.

FRAGRANCE PREP: Add 2 oz. Pure Honey Fragrance Oil and 2 oz. Sweet Meyer Lemon Fragrance Oil in a fragrance safe, glass container. Stir gently and set aside until ready to use.

COLOR PREP: Disperse 1 teaspoon of yellow oxide into 1 tablespoon of lightweight liquid oil like sweet almond or sunflower oil. Then in a separate container, disperse 1 teaspoon of Fizzy Lemonade Colorant into 1 tablespoon lightweight liquid oil. Use a mini mixer to disperse any clumps.

ONE: Slowly and carefully add the lye to the water and gently stir until the lye has fully dissolved and the liquid is clear. Set aside to cool.

TWO: Thoroughly melt the Lots of Lather Quick Mix (remember to fully melt then mix your entire container portioning). Once the lye water and the oils have cooled to about 100-110 degrees (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend until thin trace. If you’d like a harder bar of soap that releases faster from the mold, you can add sodium lactate to the cooled lye water. Use 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you’d add about 4 teaspoons sodium lactate.

THREE: Once the batter has reached a light trace, add the fragrance blend and stick blend for several seconds to combine.

THREE: Once the batter has reached a light trace, add the fragrance blend and stick blend for several seconds to combine.

FOUR: Add 1 tablespoon dispersed Fizzy Lemonade Colorant and 1 teaspoon dispersed Yellow Oxide and use a whisk or stick blender to mix in the colorants.

FOUR: Add 1 tablespoon dispersed Fizzy Lemonade Colorant and 1 teaspoon dispersed Yellow Oxide and use a whisk or stick blender to mix in the colorants.

FIVE: Add the honey to the soap batter, and use the stick blender to incorporate the soap into the batter.

FIVE: Add the honey to the soap batter, and use the stick blender to incorporate the soap into the batter.

SIX: Once the soap has reached a nice thick trace, pour the soap into the molds. Remember, this recipe made two batches of soap. =)

SIX: Once the soap has reached a nice thick trace, pour the soap into the molds. Remember, this recipe made two batches of soap. =)

SEVEN: Use a spoon to create a nice textured top. Spritz the top of the soap with 99% isopropyl alcohol to prevent soda ash. One of the soaps went into the freezer, while the other sat out on the counter at room temperature.

SEVEN: Use a spoon to create a nice textured top. Spritz the top of the soap with 99% isopropyl alcohol to prevent soda ash. One of the soaps went into the freezer, while the other sat out on the counter at room temperature.

After about 30 minutes to an hour, the loaf of soap left on the counter began to go through an extremely hot gel phase. The entire loaf started to caramelize due to the honey content, and the color started to deepen. The center of the soap is the most insulated and the warmest area of gel phase. Check out that dark brown color!

After about 30 minutes to an hour, the loaf of soap left on the counter began to go through an extremely hot gel phase. The entire loaf started to caramelize due to the honey content, and the color started to deepen. The center of the soap is the most insulated and the warmest area of gel phase. Check out that dark brown color!

Check out that awesome gel phase in the center of this soap! The extra sugar from the honey increases the temperature of cold process soap.

Check out that awesome gel phase in the center of this soap! The extra sugar from the honey increases the temperature of cold process soap.

In addition, you can see that the soap is becoming so hot that the top is cracking. Cracks in soap does not affect the quality, but is an aesthetic issue. Cracking means that due to the heat, the soap is expanding.

The other loaf of soap was left in the freezer overnight. Once removed, it was still a nice creamy color and texture. But once it was unmolded, I noticed on the bottom that the center of the soap still went through gel phase, despite being in the cold freezer. It just goes to show the power of extra sugar in cold process soap! If I had used less honey, this soap most likely would have not gone through gel phase. In addition, soaping with cooler temperatures will prevent this.

The other loaf of soap was left in the freezer overnight. Once removed, it was still a nice creamy color and texture. But once it was unmolded, I noticed on the bottom that the center of the soap still went through gel phase, despite being in the cold freezer. It just goes to show the power of extra sugar in cold process soap! If I had used less honey, this soap most likely would have not gone through gel phase. In addition, soaping with cooler temperatures will prevent this.

The soap that was placed in the freezer still went through a partial gel phase.

The soap that was placed in the freezer still went through a partial gel phase.

It’s so interesting to see the difference between the two bars. Clearly, the sugar in both bars caused them to become quite hot. The soap that went into the freezer (shown on the right, below) became hot in the center, where the soap was insulated. The soap that was closer to the outside of the mold stayed cool due to the temperature of the freezer. It’s crazy that a freezer was not able to fully prevent gel phase! If less honey was used, the soap may not have gone through gel phase at all. In addition, soaping with cooler temperatures may have prevented the partial gel phase.

It’s so interesting to see the difference between the two bars. Clearly, the sugar in both bars caused them to become quite hot. The soap that went into the freezer (shown on the right, below) became hot in the center, where the soap was insulated. The soap that was closer to the outside of the mold stayed cool due to the temperature of the freezer. It’s crazy that a freezer was not able to fully prevent gel phase! If less honey was used, the soap may not have gone through gel phase at all. In addition, soaping with cooler temperatures may have prevented the partial gel phase.

On the left, the soap was left at room temperature. On the right, the soap was placed in the freezer.

On the left, the soap was left at room temperature. On the right, the soap was placed in the freezer.

Even more interesting, you can see smell specks throughout the bar on the left, and inside the gelled portion of the soap that was placed into the freezer. Both soaps have been pH tested, and are not lye heavy. In addition, these bars have been used without irritation, so the specks are not lye pockets or crystals. Though I have theories, I’m not 100% sure what these specks are caused from, but it’s clear heat is playing a role. Interestingly, the small specks do not occur in the areas where the soap (on the right) did not go through gel phase. The specks only appear in the gelled portion of the soap. There is also a very clear cluster of white spots all around the gelled center.

One theory is these specks are palm stearic acid. The Lots of Lather Quick Mix contains palm oil, which is made up of several different kinds of fatty acids. One of these is stearic acid, which solidifies at a different temperature. Stearic acid is why it’s so important to always thoroughly melt your entire container of palm oil; the stearic acid tends to sink and solidify first as the liquid oil cools. This means the stearic acid is unevenly distributed throughout the palm oil container. The specks only seem to occur in the areas where the soap became extremely hot. In particular, the ring of white specks in the soap that was placed in the freezer suggests the stearic acid cooled quickly in this area and clustered together.

Another theory is these specks are the sugars in the honey crystallizing. It’s hard to see in the photos, but the soap that was left at room temperature and became very hot has a glossy, shiny texture. When you think about how sugar and honey behaves, it makes sense that when it becomes very hot, it forms a type of crystal…like a rock candy! The overall texture of the soap is extremely brittle and rather crumbly. Most of the bars crumbled as they were cut. Usually, crumbly bars hint at lye heaviness, but these bars are perfectly balanced. Below, you can see the unique texture inside the bars. My big take away from this experiment was 2 teaspoons honey per pound of soap is way too much. =) Another theory is that the heat may have also caused the soap to expand on the inside, and the small dots are mini heat tunnels. Check out this crazy heat tunnel I experienced several years ago!

The inside of the bars that went through an extreme gel phase were rather crumbly and dry.

The inside of the bars that went through an extreme gel phase were rather crumbly and dry.

If you use honey in your cold process soap, what are you tips and tricks? I would love to hear how you make it work for you! This little experiment demonstrated the importance of keeping temperatures cool when making soap with additional sugars, such as honey. If you have experienced these little “specks” in your soap, I would love to learn more about your recipe and techniques. Unfortunately it’s so hard to prove for sure if the specks are stearic acid, or simply soap that became so hot that the crumbly texture occurred. Just remember when working with honey, don’t add too much and keep your soaping temperatures cool!

Good day Thanks for d information on how to use homey. I want to make a beauty soap using cold process and honey too.if I use 10 litres of oil what quantity of honey ll I use?

We recommend about 1 teaspoon of honey per pound of soap. The 1 liter is about 2.2 pounds. What is the total weight of your soap, including water and lye?

Hello! I was wondering about adding honey to soap, and was so happy to find this tutorial. I went ahead and tried this out last weekend, and followed your suggestions of using 1tsp of honey per lb of soap, and put the soap in the freezer to set.

I ran into a bit of an issue when cutting the soap, though. I’m rather new to soap making, so I’m not sure if it was the knife I was using, the mix of oils, or if I didn’t let it set the appropriate amount of time, but when I went to cut my soap it cut perfectly until I got to the bottom half of the soap, at which point it just split apart. It left it very rough at that point and crumbly looking. do you have any suggestions for how to avoid this or any ideas as to why this might have happened? Any help would be much appreciated!

I can definitely help you troubleshoot. When did you cut the soap – specifically, how many days since you made it? Do you notice a darker ring of color in the middle?

-Kelsey with Bramble Berry

Thanks for the response!

I had left it in the freezer for about 24 hours, and then let it sit out on the counter for another 24 hours or so. It did have a bit of a dark circle in the middle. Do you think the gel phase there just made it too crumbly? Should I leave it in the cold for longer?

The 24 hours should be enough time to keep it cool. If it does get really hot, it can get crumbly. However, a small gel ring shouldn’t make it too crumbly. I would recommend waiting 5 days and pH testing it just to be sure it’s around 9-10: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

If the soap is lye heavy it can be crumbly, so let me know how that pH test goes. Once we confirm or eliminate lye heaviness we can go from there. 🙂

-Kelsey with Bramble Berry

Hi

I mixed sugar and salt in water added the lye to it. it was going fine. added oats and then i added Lavender oil 50g. and then i noticed the batter getting curdled. i quickly added the color little by little. but the colour was kind of eaten up by the batter. it remained light brown nomatter how much colour i added. then i quickly put the batter in the mold. and scraped the bowl. after an hour i see the purple colour creeping in little by little. but it looks kind of grainy. should i just throw away the batch. why did this happen ? is it the fragrance. ? this is the second type of Lavender i am using. recipe below

I really hope you can help me.

this is my recipe.

Coconut oil – 220 g

sunflower oil220 g

soybean oil330 g

palm oil – 330g

Sugar 50g

Salt 25g

Lye – 149.46 g

water – 363g

oats – 2 tablespoons

I’m wondering if it may be temperature related! What temperatures were your oil and lye? Did it start to thicken as soon as the lye was added? Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry

Oh wow! The lemon honey soap that I recently made looks very similar to yours, in that white spots also formed within the soap, and it wasn’t lye heavy (no zap with the tongue test). I wish I can upload a picture of the soap!

The only weird thing is that there are more white spots on the outer edges of the soap (near both ends and near the top), which is unlike yours where the white spots are more pronounced in the middle of the soap.

I also think I used way too much honey (for approximately 2 pounds of oil, and I used about 2 tablespoons of honey). My soap wasn’t as crumbly though, when I tried to cut it.

Hmm, I’m wondering if it may be hard oil that started to solidify. If you have a Facebook page you can message the picture and your recipe/temperatures to us! That would be really helpful. 🙂

Bramble Berry Facebook page: https://www.facebook.com/BrambleBerry/

-Kelsey with Bramble Berry

I used 100% extra olive oil in this process. During the light trace I added honey.Once it has traced I poured into the mold. After 20 hour in the mold it looked perfectly fine. However, when I wanted to remove from the mold on the 24th hour found appearance patches of honey on the top and also like water droplets. Need your advise on this.

Those droplets may be caused by several factors, including separation, temperature or the honey itself. What temperatures did you soap at, and how did you store your soap? How long did you stick blend for? Also, how much honey did you use in your batch? Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry

Hi! Need help!! Made a cold process Honey Oat Soap and it accelerated after pouring honey, did not manage to pour it in the mold right away and solidify. So I tried both the oven and microwave rebatching technique which I found on your site and added a cup of fresh cow’s milk per pound of soap. Its been 4 days now and looks like the soap is taking some time to harden and noticed the parts that hardened has grew some dark spots inside which look like molds. Do you think its still safe to use them? And is there a way that I can save my “Unsuccessful Rebatch Soap? Thanks a lot in advance, don’t want this to go to waste!

Barbie

Hi Barbara!

My worry is that the soap may be soft because the milk was added after it started to saponify (turn into soap). That means the milk itself didn’t turn into soap, but instead just mixed with the batch and made it softer. I would recommend waiting another week or two to see if it hardens up! You’ll also want to pH test it to make sure it’s 9-10 pH. Find out how to pH test soap here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

Let me know how the soap looks and how the pH test goes! I can help you with some options for your soap. 🙂

-Kelsey with Bramble Berry

We’ve made a batch of solid shampoo with honey on the recipe and kept it warm instead…duh! If only I checked your blog first… After 48 hours the soap is still soft, do you think it will ever become hard?

It should harden up as it cures! What oils are you using in your recipe? A lot of soft oils mean the soap will be quite soft at first, but will harden up in 4-6 weeks. 🙂

-Kelsey with Bramble Berry

It`s hardening up! 🙂

We used olive, coconut, palm, avocado and castor oils. The recipe also called for karite butter and yogurt. I just realized the yogurt was sweetened when the soap was on the mold. Well it was our first time, it happens. The ones we put on silicon molds are behaving better than the one we put on the plastic mold.

Oh that’s awesome, I’m glad to hear it’s hardening up! It should continue to harden as it cures. 🙂

-Kelsey with Bramble Berry

Hi, I want to make a simple coconut oil soap but instead of water I want to use rice milk. I was thinking that I could add honey too. The calculator says that my ingredients will yield about 2.5 lb of soap. Does that mean that i can use up to 2.5 tsp of honey? There aren’t many recipes out there for rice soap so I would like your opinion.

The 2.5 teaspoons is correct! We recommend about 1 teaspoon of honey per pound of soap. Are you wanting to make a 100% coconut oil soap with milk? Let me know and I can offer some tips. 🙂

-Kelsey with Bramble Berry

As a beekeeper, using honey is kind of a staple ingredient in my soaps – kind of a selling point. Since I always use honey in my soaps except for salt spa bars, I was stunned when my “earth: a hunter’s soap” has honey seeping out of it. At least I say honey as it’s a shimmery, stickiness on the bar. Such a sad case as I did a cool looking “camo” type swirl. This batch was made over 5 weeks ago and I cure in a room with dehumidifier running. Guessing either just using these personally OR rebatching is my only choice. So odd of an experience since this is the first time it has happened in all my batches.

Oh I’m sorry about that Janel! How much honey did you use in your batch, and how did you store the soap? If the soap gets a bit too hot that honey can separate. Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry

I make a CP soap that incorporates honey M&P soap. I make the CP base and then add M&P soap with honey added to it. I melt the soap in a saucepan and put the honey into it.. heat it up well (almost bubbling) and then pour it over the CP (making sure I pour high enough so it penetrates the soap). I’ve never had a problem with seeping whatsoever. No mold or odd smell from it going bad either. It looks fabulous when its cut! I still have a few bars I made 3 yrs ago and they are still good!!

That sounds awesome! Nice and moisturizing on the skin. 🙂

-Kelsey with Bramble Berry

I made my first batch of buttermilk and honey soap last night, with 50% olive oil, 25% Shea butter, 20% coconut oil, 5% castor oil. Half the liquid as buttermilk (frozen), the other half ice cubes, and 1/2 a cup of organic honey. I added a couple of tablespoons vitamin e at trace with the lavender and lemongrass essential oils. Oils were 125 Fahrenheit when mixed with the lye water & poured. I used a cardboard box and left it on the counter with no top. It went through a mild gel phase but no cracking and is a beautiful creamy yellow. It’s soft so I only trimmed off the edges and cut it into large blocks. I’ll cut the bars next week. I cannot wait to try it!

Oh that sounds like an awesome recipe Cory! Nice and creamy. Let us know how it feels on the skin. 🙂

-Kelsey with Bramble Berry

I made a cp soap with honey before from another website’s recipe. I let the soap sit for three days before cutting and unfortunately when I did all the honey spilled out from the soap like a waterfall! It had risen and separated from the soap mixture to be a pool of honey in the middle of the bar… I followed the recipe exactly and found similar results in the comments of the recipe’s web page. Any explanation as to why the honey separated?

Hi Ruthann!

I’m sorry about that! Can you tell me a bit more about your recipe, including how much honey you added? Also, where did you set the soap to harden? Let me know and I can help you troubleshoot. 🙂

-Kelsey with Bramble Berry

Hey!

All the comments were so great- I learnt so much this evening!

Has anyone ever played around with Eucalyptus Honey before? I’m going through a big honey soap phase and love eucalyptus so when I saw it was an option to get the two together I had to order some in.

Any advice before I dive into a batch? I usually just leave my soap on the counter insulated because I prefer the look of the gel phase.

Thanks!

We haven’t given eucalyptus honey a try. It sounds awesome though! I would recommend making a small test batch to see how it works. We like to use about 1 teaspoon per pound of soap. When working with honey, we recommend popping it in the fridge or freezer for 5-24 hours. If the soap gels it can overheat and cause the crumbling/bubbles seen in the picture above. Let us know how the honey works! 🙂

-Kelsey with Bramble Berry

I use honey and beeswax in every recipe and I’ve never had discoloration. I use pure honey from my own beehives. Honey that’s processed from stores is 1/2 corn syrup. Perhaps this is an issue.

I also dissolve honey in 1/2 the water I use for the lye, I mix the lye in one container of measured water and wait until the lye reaches roughly 90F before adding the remaining measured water where I had dissolved the honey together. The lye turns pink. The honey will reheat the lye, so I wait until the lye/honey water is roughly 80-90F before mixing with the oils. I melt beeswax in my oils as well. The beeswax is also from my own hives, so it is pure beeswax. If I’m mixing in color and my fragrance, I use a very light trace. This works best for me. I also am making smaller 2 pound batches of soap at a time. I set on my counter, cover with plastic, cardboard top and terry cloth towels.

I’m a fairly a new soaper, but I’m in love with soaping. I love honey and I love beeswax, I use both in several products. I clean and filter my own wax and wax needs to be moniterd quite well during the melting process when cleaning.

I love a great challenge. I will use honey and beeswax in almost every soap recipe I make. The soap comes out beautifully and I love the lather from the soap as well as the moisturizing effect. Homemade cold process soap is absolutely wonderful! ❤️

Hi Nicole!

Thank you so much for sharing your great tips! It sounds like you’ve found a perfect method for working with honey. I bet it feels nice and creamy as well. I love when you find a perfect soap recipe. 🙂

-Kelsey with Bramble Berry

Thanks for the info. I was told to always put my honey soap in the fridge or freezer. You leave yours on the counter and it does fine?

How much beeswax do you put in your recipe? I buy my honey and beeswax from a local honey store – no store bought honey. I’d love to try it with honey and beeswax.

Thanks.

Hi Sandy!

We typically recommend beeswax at 8% or less in the recipe! Because it has a high melting point, you will need to soap at higher temperatures to keep it from solidifying. We typically soap around 170-180F. You can learn more about soaping with beeswax here: https://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/beeswax-spoon-plop/

-Kelsey with Bramble Berry

Hi Nicole,

I’m just starting out and would love to know more about your honey & bees wax soaping. Is it possible to read more about what you’re doing that’s working and what not to do?

Also, would you or anyone else (maybe Kelsey) know if lye destroys any of the health benefits of the honey?

Adrian

Hi Adrian!

It’s tough to say! Cold process soap is very harsh environment with a lot of pH changes. We’re not exactly sure what makes it through that process. I can tell you soap made with honey does have a nice creamy lather though. 🙂

We used it in the Pure Honey Cold Process Soap Tutorial: https://www.soapqueen.com/bath-and-body-tutorials/pure-honey-cold-process-soap-tutorial/

-Kelsey with Bramble Berry

I’m new to cp soap making and I tried my hand in a porter honey beer bar. I got my lye beer solution I got down to ninety degrees and my oils were at one hundred degrees. It seemed like it took awhile to reach trace but once I achieved a good trace then I poured into my mold. I put my mold in the fridge and and waited A full 24 hours later. Once I unmolded and cut Into bars and I noticed the center was gelled while the outside turned a beautiful opaque color. I’m confused because I soaped at a cooler temp so I’m unsure if I did something wrong. The soap was soft as well so the end pieces fell in hal(I did pulverize oats between the layers) I wonder if the recipe I used created a softer bar of soap. I used lard, coconut oil with a 76 degree melt temp, oilive oil, castor oil, grape seed oil, and sweet almond oil.

Hi Laura!

We’ve had that happen as well! Because honey has natural sugar, it can heat the soap up quite a bit, even with cooler temperatures. For your next batch, I would recommend popping it in the freezer for 24 hours instead of the fridge. The extra cold temperatures should help prevent that gel phase in the middle. You can also lower the amount of honey in the bar. The more you add the hotter the bar will get, so decreasing it can help as well. 🙂

-Kelsey with Bramble Berry

Hello (:

I read that you can blend the honey with the oils prior to combining it with the lye solution–what is your opinion on this? The woman who created this recipe says it works great:

http://simplelifemom.com/2015/01/26/adding-honey-to-handmade-soap-recipe/

Also, in your tutorial you use (or least this is what you have pictured) what looks like 100% pure grade A honey–it was never specified what kind of honey one should use in soap, which is very important! It is best to use (organic) raw, unfiltered, unpasteurized honey because the more processed the honey, the less benefits it retains. I’m very surprised this was never brought up…

For those reading this, please read the following article before you purchase the cheapest honey you find at your grocery store:

http://www.institutefornaturalhealing.com/2015/08/the-not-so-sweet-truth-about-honey/

“You’ve seen the labels with ‘pure Grade-A honey’ printed on them. Well brace yourself… Because they usually don’t mean a thing.

Plain and simple, most honey on sale in the United States is fake.

A sampling of over 60 varieties shows that 76 percent of honey bought in U.S. groceries isn’t actually honey. It doesn’t even contain pollen.1

So, what is this stuff you’re buying as a ‘healthier’ sugar substitute?

It’s another processed product stripped of nutritional value. Processing honey removes its pollen, antioxidants, and nutrients. What you are left with is sweet syrup.

Honey manufacturers say removing pollen helps the shelf life of the product and makes it impossible to trace where it came from. They also say clear honey just looks more appealing.

Unbelievably, they also add in artificial sweeteners and corn syrup to cut costs and make a sweeter product.”

(It is infuriating/disturbing how mindblowingly deceitful the food industry is… Which is why it’s always very important to do your research!)

Would you recommend using organic? Or should I save my money? It’s hard to know because it seems that many additives lose some of their benefits when incorporated into soap… And are better used directly on your skin/hair–at least the more expensive ones.

Hi Daniel!

Thanks so much for your thoughtful comment! In cold process soap, it’s difficult to say whether all the nutrients from the honey make it through the saponification process. Saponification involves a lot of harsh pH changes that may affect the honey itself. I can tell you soap made with honey does have nice creamy lather though. 🙂

You can use whatever honey you like. We used regular honey from the grocery store. If you prefer organic, you can definitely use that in your recipe. That’s what’s so nice about making your own soap – you can customize it any way you like!

As for adding the honey, we like to add it at trace. Because honey accelerates slightly, it can thicken your soap quickly if it’s added to the oils before the lye. I would recommend making a small test batch with both methods to see which one you prefer. 🙂

-Kelsey with Bramble Berry

Thanks for your response (:

It seems the saponification process strips many ingredients of the benefits they offer in their natural state, which can certainly make choosing the grade/quality you want a challenge. Do you have any advice on this? Perhaps that as long as the ingredient is “pure”, then grade doesn’t particularly matter? I would like to make high quality soap, but I don’t want to spend a fortune if lower grades of certain ingredients will provide the exact same benefits as their superiors.

I’ve read that egg yolk, like honey, can also help increase lather. However, I haven’t figured out how you’re supposed to incorporate it into a recipe. Have you ever used egg yolk? I’ve read that when you use egg yolk you’re supposed to do a water discount equal to the weight of the egg yolk(s). On a soaping forum someone suggested one egg yolk PPO. If you have any advice on this that’d be great!

Oh! And sugar! I’ve read that that too will increase lather. Have you ever used sugar in your soap?

Thank you (:

When choosing the honey, we recommend getting a pure honey with no additives. Additives can sometimes do weird things in your batch. As for the grade, it’s definitely up to you! We’ve used several different grades and haven’t noticed a huge difference in the feel of the soap. I would recommend a couple small test batches with some different grades of honey. That way you can decide if you feel a difference in the soap!

We have used egg yolks before! They help create a nice creamy lather. We recommend mixing about 1 ounce of oil to 1 room temperature egg yolk per pound of soap. If you want more, you can increase that ratio. Then, at trace, pour the egg mixture through a strainer to catch any clumps and incorporate with a whisk. There isn’t a lot of excess water in the yolks, so we didn’t water discount. You can if you like though! I would recommend starting at a 5% discount.

You can find the Egg Yolk Secret Feather Swirl in Anne-Marie’s new book, Pure Soapmaking: https://www.brambleberry.com/Pure-Soap-Making-How-to-Create-Nourishing-Natural-Skin-Care-Soaps-P6298.aspx

You can also add sugar for nice creamy lather! We have done that before. You can incorporate that several ways – you can dissolve the sugar in distilled water before adding the lye, then add that mixture like normal. You can also mix the sugar with distilled water and add it at trace. Just make sure to discount the water from the main batch so the soap doesn’t get too wet. We recommend about 1 tsp. of sugar per pound of soap.

Make sure to pop the soap in the freezer afterward for 5-24 hours! Like honey, sugar can overheat the soap. A freezer will keep it nice and cool. 🙂

-Kelsey with Bramble Berry

Thanks for all the info!

Here are instructions I found for making a sugar “syrup.”

“Make a ‘simple syrup’ ahead of time by taking two cups of sugar and one cup of water and slowly heating them on the stove. Stir gently until all of the sugar has dissolved. Let it cool and pour it into a bottle to use when you’re making soap. Add ½ to 1 tsp. of the syrup per pound of oils you are using* to your soap, at trace, with your other additives, but before your fragrance oil.”

Think that would work well? Since the ratio is 2:1–so twice as much sugar than water–do you think it would still be necessary to do a water discount? If I do 3 tsp of this mixture/solution that would only be a water discount of 1 tsp. Also, do you have any idea how long this sugar “syrup” might last?

I’ve read that if you’re adding egg yolk you want to allow the oils and lye solution to cool down to about 90° F before combining them so the eggs don’t scramble. What temperature range would you suggest?

And Anne-Marie’s new book looks awesome (: Is it only available online?

You can make a simple syrup as well! Because it’s such a small amount of liquid, I don’t think you would need to water discount. I generally like to water discount if I’m adding an ounce or more of extra liquid, but under that doesn’t make the bars too wet. 🙂

As for the sugar syrup, I believe it lasts a couple months in the fridge. I make simple syrup to sweeten my coffee and keep it in the fridge for a month or so!

For the egg, we do recommend soaping at lower temperatures. Around 90-110F is a good range, as much warmer the egg can scramble. To help, you can heat up the oil you’re mixing the egg in with a bit (like 20 seconds in the microwave). That will make the egg warmer before adding to the full batch so there is a smaller chance of scrambling. It’s sort of like baking when you mix some hot liquid with an egg before adding that mixture into the recipe. 🙂

Anne-Marie’s new book is available at BrambleBerry.com, Amazon and Barnes and Noble!

-Kelsey with Bramble Berry

Thank you Kelsey!

I will definitely check out the book (:

You’re welcome!

-Kelsey with Bramble Berry

Hey (:

Instead of using granulated sugar, can you use brown sugar? I know you can use brown sugar in soap but will it have the same effect as regular sugar?

We haven’t done a lot of testing with brown sugar in soap, so I’m not entirely sure! I imagine it would add lathering properties like regular sugar. I would recommend making a small test batch with it. 🙂

-Kelsey with Bramble Berry

Will do! Thanks for the response!

You’re welcome!

I use honey and beeswax in all my soaps, as I am a beekeeper by trade. This soap addiction, er pardon me, hobby, is my way of adding “value added products” to my product line. I have seen all of the above happen while making soap. For me the “deciding factor” in precisely how I make my soaps is the FO. FOs that are already prone to discoloration, and/or overheating are less picky to work with. I can use 2-3 tsp of honey ppo. For soaps that have “light” FOs, I use 1 tsp ppo. The other end of this balancing act is beeswax which has a high melt point of 145F or so. I have never had a blowout like AM warns of. But then, when I melt my wax, I do it in 1 min. bursts, and stir/swirl for 30-60 seconds, then zap again. The beeswax does have a tendency to begin to re-solidify after melting and mixing with other oils. I stir my warmed oils as they cool about every 5 minutes, at least. I don’t cool my oils past 110F, as at that point, the congealing beeswax doesn’t want to stir up and re-melt. I have experimented with mixing up my lye and water and adding the honey to that, before covering it with plastic wrap, and refrigerating that for 12-24 hours before use. That cools off to about 45-50F, and helps offset the heat of the oils. I MUST SB the mix at first, while I emulsify, then I whisk. Putting the batch into the freezer next helps prevent gel. BTW, I don’t have little people in my house, and the canning jar with the painted skull and bones on it reminds my people not to touch the lye water in the fridge.

Hi there!

Thank you so much for sharing your awesome tips! I know they will be really helpful for people wanting to make honey soap. Also, what an awesome use for your leftover honey and beeswax. Your soap sounds amazing. 🙂

-Kelsey with Bramble Berry

Hi! I always find honey such an interesting thing to work with 🙂 . I have had success adding 8tbsp (yes, tbsp!) to 880g of oils (I did it on a dare). I insulated in my oven, had a nice even gel, no cracking and no partial gel. The variables that I think led to my success were : I used a water discount – the more water used, the hotter the gel. I only used water that was 2x the weight of the lye. Secondly, I have found that the best way to keep a honey soap from overheating or getting partial gel is to use very, very cool oils and lye. I used both at about 24C, which was lower than room temp here. Thirdly I dissolved the honey in part of my water and froze it, then once the lye water cooled I slowly combined the lye solution and frozen honey solution. It warmed up a bit but not scorching hot, then I cooled that solution back down to 24C before adding to the oils. Otherwise, I find the batter heats up as soon as the lye contacts the honey, making it a hot batch even if you soap cool. This way the heating up when the lye contacts the honey happens before its in the soap batter. So they are the tricks I used – and the result has been curing for a while. I have used a small piece and it’s just wonderful. 🙂

That is awesome Lisa, thanks so much for sharing your tips! Mixing the honey with water and freezing it sounds like a great idea. Also, I love that you did it on a dare. It ended up being a beneficial dare! 🙂

-Kelsey with Bramble Berry

Hi, I’m new to soap making and want to try honey in my second batch. I don’t have a loaf mold yet and will be pouring the soap in smaller 3-4 oz, silicone molds. Do you think the batter being separated like this will keep it from getting too hot? Should I still put it in the freezer?

Hi Sarah!

Pouring the soap into separate cavities will definitely help keep it cooler! I would recommend still popping it in the freezer to be extra careful. That way the soap will stay nice and cool. 🙂

-Kelsey with Bramble Berry

Thank you! Can’t wait to get started!

You’re welcome! Have fun. 🙂

-Kelsey with Bramble Berry

Probably not a lot of guys here, but this is my hobby. I’m a recovering alcoholic and I’ve replaced soap making for drinking. I’m very experienced with hot and cold process and I guess I’ve just been lucky with honey because mine is always awesome and I never even measure. I divide it into 3 batches: one white, one with cocoa powder and one with a small amount of honey and drop swirl the three. The result is a gorgeous bar of soap. However, the top does do what you all refer to as “alien brain.” It’s a very thin layer and hardly noticeable so I just leave it. I don’t sell my soap, I give it away to those less fortunate so a less than perfect bar is OK.

That’s awesome, sounds like you’ve found a great recipe! I bet your soap is amazing. I just love the way honey soaps feel, the lather is amazing. Thanks so much for sharing your experience with us. 🙂

-Kelsey with Bramble Berry

Hi! 🙂

I’m new to soap making and I am very excited to start my first batch. The soap I will be making will be all natural ingredients and I would like to add organic sugar to my recipe to help with the lather of the soap. I will be making the sugar a staple product in all of my soaps. The trouble I am having is knowing how much sugar to add to the recipe and when to add the sugar. I’m not sure if I should be adding it to my lye/water solution or if I should be adding the sugar directly to the mix after I mixed together the lye & all of my oils and butters. Should I be diluting the sugar? Sorry for all of the questions but I just can’t seem to figure this part out. Any suggestions??

FYI my recipe contains 4 different types of oils plus cocoa butter and shea butter 🙂

Hi Dee!

That’s so exciting, I think you’re going to love soapmaking! 🙂

There are several ways to add sugar to your soap! The first is to dissolve it in water before adding your lye. You can also take 1-2 ounces of water from your batch, mix in the sugar and then add that solution at trace. If you’re just starting out, I would recommend adding that sugar at trace. Sugar tends to accelerate your soap, so it will move a lot more quickly when added in with your lye water.

As for the amount, we recommend 1/2 tsp. to 1 tsp. per pound of oils in your recipe. You don’t need a lot! That amount will give you some nice lather. 🙂

As with the honey, we recommend freezing the soap afterward. The sugars can caramelize in the soap, causing some discoloration. Keeping it cool in the freezer for 5-24 hours will help prevent that!

-Kelsey with Bramble Berry

I made a Honey cp soap on the 21st. Made sure to leave it on the counter and not to insulate it. Here is my recipe, maybe you see something wrong with it. 27oz Olive Oil

4oz Cocoa Butter

.5oz Castor Oil

.5oz Beeswax

2.76oz Raw Honey

.5oz Rosemary EO

.33oz Orange x5 EO

.5 Litsea Cubeba EO

10.56oz Honey infused Distilled Water – add 1.3 TBSP Raw Honey to hot water and set to cool in fridge.

4.05oz Lye

I ran the recipe through three lye calculators and the lye/water ratio seem to be correct.

The soap turned a beautiful earthy orange when I added the lye to the oils (about 95F), I then added the EOs and at the end the rest of the honey (mixed with some of the warm oils), mixed it all well and poured at light trace. I had bubble wrap in the bottom and wanted the batter thin enough to get the details. Kept a close eye on it. The mold was slightly warm, it never went through the gel phase, and in the morning it turned into a creamy peach. I noticed the soap was very soft but in a cream cheese kind of way. Left it until Monday morning and it came easily out of the mold. This morning I cut a slice, since it has hardened somewhat, and it is still very creamy and sticks to my knife. Is it just a matter of time or is it a lost batch? I know the olive oil ratio is high but I’ve made Castile soap and never had this issue. Sorry for the longwinded post. Thank you for any advice you can give me.

Hi Farida!

Thanks so much for all the recipe details, that really helps me troubleshoot. 🙂

I think your batch is just fine, it just needs a little bit of cure time to help it harden up! Your batch has quite a bit of olive oil, and even with the beeswax and cocoa butter for firmness, it will take a bit longer to harden up. I’ve also noticed that batches with honey are a little bit softer and take a bit longer to harden up as well.

I would recommend letting those bars cure for 4-6 weeks (you may need to cure them longer because of the high olive oil content). After curing, they should firm up nicely and be ready to use. 🙂

To help make your bars firmer, you can add 1 tsp. of sodium lactate per pound of oils to your cooled lye water. Read more about sodium lactate here: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-sodium-lactate/

You can also water discount your soap. With less water in the initial batch, the soap will harden and cure more quickly. Keep in mind water discounted soap does thicken more quickly, so be prepared to move a little faster! Read more about how to water discount here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/water-discounting-cold-process-soap-how-why/

-Kelsey with Bramble Berry

Kelsey, thank you for your reply, you make me feel so much better about this batch. I only cut one bar off and stopped because of some of the soap sticking on the knife. I will let it sit and test cutting every day. Thank you, again.

You’re welcome Farida! Enjoy your bars. 🙂

-Kelsey with Bramble Berry

Hey there! the strangest thing happened to me and i cannot seem to find answers anywhere help!!

I made my cp soap with 100% olive oil and added honey

i did not put it in the fridge because i like the brown color , instead i put it close to my AC where i is cool just in case to avoid volcano.

it did not go through the gel phase, it did not overheat, and its taking more that usual to harden.

for a while it had a pools of liquid on top but it reabsorbed it, i already unmolded it but its really soft, even though i did water discount it.

i used 2400 g olive oil – 305g lye – 720 g water and 7 tablespoons of honey

any ideas please?

Hi Alejandra!

I think that is completely normal! Soaps made with 100% olive oil take longer to harden and cure. Castile (100% olive oil) soap can take several weeks to unmold and up to 6 months to cure. It will be a bit faster with a water discount, but will still take longer to harden. Although they do take a bit longer, the end result is totally worth it! They feel really gentle and luxurious on the skin. 🙂

Read more about castile soap here: http://www.soapqueen.com/bramble-berry-news/olive-oil/

You can speed that process up though! You can add 1 tsp. of sodium lactate per pound of oils to your cooled lye water. That helps the soap unmold more quickly. Read more about sodium lactate in this Sunday Night Spotlight: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-sodium-lactate/

I’m not entirely sure why there will pools of liquid. The soap may have gotten a bit hot and started to separate, but it sounds like the soap dried nicely and should be just fine. 🙂

-Kelsey with Bramble Berry

I add 2 tablespoons of honey to 4.25 lbs of goat’s milk soap at trace. I don’t add any colorants or FOs to the soap, but I do add Sodium Lactate to my lye milk. The Sodium Lactate gives the soap the same level of hardness that my non-honey soaps have because honey tends to produce a softer bar. I do end up with a darker colored bar from the honey, but I don’t mind, since its easier to distinguish it from the others and you still get a slight sweet smell. I would recommend trying honey though, as it is by far my best seller! I did learn the hard way about measuring the honey though, when I ended up with a dark crumbly bar like you’re showing. However, a quick rebatch mixed with non-honey soap allowed me to save it for my shower. 🙂

Your bars sound amazing – creamy and rich! That’s a great tip about the sodium lactate as well. I’ve noticed honey bars are a tad softer. Also, I love rebatching – you can save almost any batch. 🙂

-Kelsey with Bramble Berry

Sunday Night Spotlight: Sodium Lactate: http://www.soapqueen.com/bramble-berry-news/sunday-night-spotlight-sodium-lactate/

How to Rebatch Soap: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/soap-queen-tv-presents-how-to-make-rebatch-soap-2/

I tried my own version of honey soap-similar to this recipe and got the streaky-crumbly bar, too, very similar to the room temperature gelled soap shown here. The oils I used was coconut oil, palm oil, olive oil and castor oil–heavy on the palm and coconut however and –added beeswax too(!!!). So I would like to try the re-batch idea next. What ratio of non-honey to honey bar soap would you recommend? one part honey to one part non-honey or other ratio? Also when trying the recipe again, I would change the ratio of the types of oils I used: I had a relatively high amount of coconut and palm oil, perhaps reduce these and increase the olive oil. (Your thoughts on the ratios of oils? I’m not using milk products at this time) And last, since I don’t have sodium lactate to harden the bar, I was thinking of just adding salt ie, 4 tsps to 4oz of water–this was mentioned in another of your blogs regarding the use of a high amount of olive oil in the soap recipe. BTW love your blogs and your products –Thank you!

Hi Dee!

If those bars are on the drier side, I would recommend adding an equal amount or double of a nice soft recipe. That will mix with the honey soap and help produce a softer bar overall. You may like our Castile Rebatch soap. It is made with 100% olive oil, so it’s nice and soft: https://www.brambleberry.com/Grated-Rebatch-Soap-Base-Castile-P5233.aspx

Learn more about rebatching soap here: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/soap-queen-tv-presents-how-to-make-rebatch-soap-2/

When you make this recipe, you can change the oil amount if you like! You can up the olive oil to around 40%, and drop the coconut and palm to 30% and 30%. You can even up the olive oil to 50% if you like.

It will also help to add just about 1 teaspoon of honey per pound of soap, and pop that soap in the freezer afterward. Keeping the soap cooler will prevent it from getting too hot and crumbling. That way you still have a firm bar, but no crumbliness. 🙂

Also, you can definitely use a salt water solution if you like to harden the bar! To make the solution, mix 1 teaspoon of regular table salt into 1 ounce (by weight) of warm distilled water. Stir until the salt is fully dissolved. We recommend 1 teaspoon of salt in 1 ounce of water per pound of soap. Make sure to discount the salt water solution from your liquid amount. Then, add the solution at trace. The salt water solution was used in the Palm Free Vertical Twist Tutorial with great results: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/palm-free-vertical-twist-tutorial/

Hope that helps! Also, so glad you love the blog and products. Thanks a bunch for your business. 🙂

-Kelsey with Bramble Berry

Thank you! I’ll give your suggestions a try and let you know what happens!

You’re welcome! Looking forward to hearing how your soap turns out. 🙂

-Kelsey with Bramble Berry

I noticed the specks when I added goats milk slurry from powder in cold process soap. I added the goats milk at trace but I was soaping at 125 degrees F. I was using a wood mold, so that is insulating of itself but I did stick it in the freezer overnight. It still gelled in the center with the specks. Of course, the goats milk carmelized and discolored the otherwise natural color soap.

Hi Jeanne!

Wood molds do tend to keep your soap a little warmer! They insulate soap really well. I have had some very warm soap in those molds before. 🙂

To help prevent the specks and discoloration, you can place the soap in individual cavity molds, like the 12 Bar Square Silicone Mold, and pop it in the freezer. The individual cavities help the soap cool more quickly, keeping your soap a nice creamy color.

-Kelsey with Bramble Berry

12 Bar Square Silicone Mold: https://www.brambleberry.com/12-Bar-Square-Silicone-Mold-P4908.aspx

I made a goat’s milk CP soap last year that came out beautiful! It didn’t have any honey and it also didn’t have any fragrance since I was making a baby bar. What I did do was pre-measure everything and kept it handy. Then, I filled my sink basin with ice and water (and I mean a lot of ice!), kept my kitchen windows open and turned on the fans. When I added my lye to the milk I stirred like crazy with my right hand but also kinda swirled the whole pitcher with my left until the lye was dissolved. Since my oils were pre-measured (and cooled), I added more ice to the sink, switched out the containers so the oil was in the sink and kept on stirring as I added the lye mix. Initially it tried to turn toward a light orange color but I did the same thing with this container (kept it moving while stirring) and it lightened up again. I didn’t leave the oil container sitting in the sink while I added ice as I was afraid my hard oils would harden. My medium to thick trace was achieved without seizing and I got it into the molds pretty easy. This soap was ready to cut after 24 hours and actually was almost a white color! I think the fact that everything was pre-measured and readily at hand really helped it be a success.

That’s awesome Jenna, sounds like that soap turned out beautifully! Having your ingredients premeasured is a great idea, that way the whole process goes quickly and smoothly! Cool temperatures are definitely the key to working with milk. That way the milk doesn’t scorch and your bars stay nice and creamy white. 🙂

Learn more about working with milk here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-add-lye-to-milk-for-cold-process-soap/

-Kelsey with Bramble Berry

I am curious if you have experienced this with hot process also? I have heard of people putting a tablespoon into a hot process batch, and it turning out fine. Seems like a lot more honey than you are using! I do both cold and hot process, but am wondering about trying honey in the hot process, and hopefully avoiding this problem. anyone do this?

Hi Kirsten!

That’s a very good question! We haven’t done a lot of testing with honey in hot process soap. Because hot process temperatures are usually around 160F, the honey may cause a bit of discoloration in the soap. It can also cause your soap to get quite hot, so make sure to have a large container so the soap has room to grow. That soap should only be about half full in the container.

I would recommend making a small test batch with the honey and seeing how it works. I will also pass that along to our testing department so we can play around with it as well! 🙂

-Kelsey with Bramble Berry

Hi,

I made a soap with honey just a week ago. I also added a lot of oatmeal. I at first thought the crumbly soap was due to not adding enough water with the oats. As I read here, it can also be due to the added honey. Thanks for the advice (I have learned always to check with SoapQueen.com before trying something new 🙂 ).

With kind regards,

Annemieke

You are very welcome Annemieke! Heat can definitely do some weird things in soap. Popping your soap in the freezer should help prevent that cracking. 🙂

-Kelsey with Bramble Berry

Thanks for the advice, Kelsey. Next time I will put it in the freezer.

I like to try new things and see what happens, both the good and the bad things. I learn a lot from it.

You’re welcome! Experimenting is a great way to know what happens in soaping. You can add new things and tweak the recipe until it’s perfect for you. 🙂

-Kelsey with Bramble Berry

I use honey in all my soaps, added to my yoghurt and dissolved then mixed with the yoghurt (100grams) and esssential oils into the soap batter at thin trace. The soap almost always sweats orange droplets 🙂

Hi Monica!

Oh no, I’m sorry about that! I’d love to help you troubleshoot. Can you tell me a bit more about your recipe? Also, how are you storing the soap? Let me know and we’ll get this figured out!

I do know if the soap gets really hot it can separate, when can cause those oil droplets. Popping it in the freezer for 5-24 hours helps keep the soap nice and cool.

-Kelsey with Bramble Berry

I use honey in one of my goats milk soaps and it is my best seller! I experienced the crumbling and cracking when I first made this soap but that was due to my honey overload and insulating during saponification. These days, I experience success with this soap everytime – no cracking or crumbling. If I get the gel phase heat circle at all, it tends to be only around the middle few bars. I don’t insulate the soap exactly but I don’t place it in the freezer either. I leave it to sit uncovered in a cardboard box but the box is covered by a towel. I soap at around 35 degrees Celcius and add the honey in at trace.

Hi Pauline!

That’s awesome, sounds like you’re making amazing honey soap! Practice definitely helps with honey soap, and it can take a bit of experimenting to find the perfect way to store it for your environment. My first honey soap got hot, hot, hot. It did have some weird cracking and caramelization, but still felt really nice. 🙂

-Kelsey with Bramble Berry

I use honey a lot in my soaps. I love the lather boost and conditioning properties that it imparts to soap. I do get the heat circle [as i call it] in the center of my soap even when I put it in the freezer (i usually soap at 100-110 degrees). it doesn’t bother me, since I’m the only one using it. I’ve found that adding honey at the end and placing the soap in the freezer overnight helps to prevent a gel

I agree, I love the lather you get with honey! Also, thanks so much for your great tip. Honey definitely loves a cool environment. 🙂

-Kelsey with Bramble Berry

I’ve never used honey but it sounds like a nice idea. I used watermelon juice once and it came out the same caramel color. I’m curious about additives such as honey, milk, extracts, etc. I’ve read somewhere that while many of these additives on their own have various wonderful properties, these properties are often altered or destroyed in the soap making and saponification process and really provide no added benefit other than label appeal. Thoughts?

Hi Michael!

That is a great question. Saponification is a rough environment, and the recipe goes through a lot of pH changes. It is difficult to say if all the properties of the additives make it through that process.

That being said, I can tell you I do notice a difference with honey soap. It’s got amazing creamy lather, and feels really moisturizing on the skin. The same goes for milk! Milk adds such a nice silky feeling to the soap.

I would encourage you to try some of the additives and see if you notice a difference. It’s definitely personal preference if you want to add them to your batches, but it may be worth a little experimenting. 🙂

Also, they are great from a marketing standpoint! For instance, when most people think goat milk lotion they automatically picture an ultra creamy, comforting bar.

-Kelsey with Bramble Berry

Thanks! I definitely do want to try the honey in a batch, and have some coconut milk I want to make too. I’m not at all put off by using additives and alternative ingredients, I just wondered how well they actually perform in CP. People ask me all the time.

You’re welcome! Let us know what you think of those soaps. 🙂

-Kelsey with Bramble Berry