The Bramble Berry studio has several sushi addicts. While brainstorming new project ideas, we kept going back to recreating a classic sushi roll with cold process soap. We tackled the project with melt and pour back in 2009, but it was definitely time for a redo. We’re thrilled with how this soap turned out.

This project is not for the faint of heart. It’s not particularly difficult, but it does take several batches of soap and a few days to complete. First, several column embeds are created to look like sushi fillings. We used LCP White and LCP Clear Melt and Pour Soap Base to expedite the process, but the embeds can also be made with cold process soap. “LCP” stands for “like cold process.” It contains less glycerin than standard melt and pour base, which makes it ideal for embeds in cold process soap.

Once the embeds are cool and hard, they are cut into random shapes. The exact shape doesn’t really matter, but they look more natural than a perfect square. For our first attempt at this project, we used a mixture of fresh cold process batter and finely chopped white cold process soap to create a “rice” texture. You can see this bar on the left in the photo below. It turned out nice, but it was a lot of work for not a huge payoff. The “rice” texture is fairly hard to see, so we skipped it for our second attempt and this tutorial.

The embeds are inserted into the Silicone Column Mold, and white soap scented with Wasabi Fragrance Oil is poured around them. The fragrance is reminiscent of wasabi without smelling exactly like it – it’s fresh, slightly spicy, and green. After about 1-2 days, the soap can be removed from the Silicone Column Mold.

The final step is “painting” cold process soap on the outside of the soap. We used a Shaving Brush for this step, but any large fluffy paint brush will do the trick. We experimented with painting the entire batch first then cutting, as well as painting the individual bars. We found painting the individual bars a little bit easier – the outer layer tended to crack when we cut the soap after.

It’s a fairly complicated project but we think it’s worth it. We think they’ll be a hit at markets – they’re a great conversation piece. They would also be the perfect gift for any sushi enthusiast in your life.

How to Make Sushi Soap

What You Need:

Sushi Embeds

Four Mini Square Silicone Column Molds

5 oz. LCP White Melt and Pour Soap Base

11 oz. LCP Clear Melt and Pour Soap Base

Chrome Green Color Block

Fizzy Lemonade Color Block

Perfect Orange Color Block

Fired Up Fuchsia Color Block

Shimmer Merlot Sparkle Color Block

Sushi Base

Silicone Column Mold

6 oz. Coconut Oil (30%)

6 oz. Palm Oil (30%)

4 oz. Rice Bran Oil (20%)

1 oz. Shea Butter (5%)

3 oz. Sweet Almond Oil (15%)

6 oz. Distilled Water (10% water discount)

2.8 oz. Sodium Hydroxide Lye

1 oz. Wasabi Fragrance Oil

Titanium Dioxide

Sushi Outer Layer

2.1 oz. Coconut Oil (30%)

2.1 oz. Palm Oil (30%)

1.4 oz. Rice Bran Oil (20%)

0.4 oz. Shea Butter (5%)

1.1 oz. Sweet Almond Oil (15%)

1 oz. Sodium Hydroxide Lye

2.1 oz. Distilled Water (10% water discount)

Black Oxide Pigment

Green Chrome Oxide Pigment

Optional: Shaving Brush

Click below to add everything you need for this project to your Bramble Berry shopping cart!

Make the Embeds

ONE: Chop 11 ounces of LCP Clear Melt and Pour Soap Base into small uniform pieces. Then, chop 5 ounces of LCP White Melt and Pour Soap Base into small uniform pieces. Add the following amounts of soap base and color blocks to separate, heat-safe containers. Melt the soap and color blocks in the microwave separately using 10-20 second bursts.

NOTE: If you have fewer than four Mini Square Silicone Column Molds, you’ll need to make the embeds in batches.

- Salmon Embed: 3.5 oz. LCP Clear Melt and Pour Soap Base + 0.5 oz. LCP White Soap Base + equal amounts of Perfect Orange Color Block, Fired Up Fuchsia Color Block, and Fizzy Lemonade Color Block + a very small shaving of Shimmer Merlot Sparkle Color Block

- Orange Embed: 4 oz. LCP Clear Melt and Pour Soap Base + Perfect Orange Color Block shavings

- Green Embed: 3.5 oz. LCP Clear Melt and Pour Soap Base + 0.5 oz. LCP White Soap Base + equal amounts of Fizzy Lemonade Color Block and Chrome Green Color Block shavings

- Light Green Embed: 4 oz. LCP White Melt and Pour Soap Base + equal amounts of Fizzy Lemonade Color Block and Chrome Green Color Block shavings

TWO: After melting one container of soap, immediately pour it into one of the Mini Square Silicone Column Molds. Place the mold into a sturdy and tall container to make sure the mold stays upright and the soap doesn’t pour out. Repeat until you’ve created all four embeds (green, light green, salmon, and orange). Allow the embeds to fully harden and cool for several hours.

THREE: Remove the embeds from the molds. Trim the sides if necessary – we like using a Clean Up Tool. Use a sharp, non-serrated knife to cut the corners off the embeds as you see fit. We cut one corner off both green embeds and the salmon embed. Then we cut the orange embed into four equal pieces to look like carrots. Don’t worry too much about how you cut the embeds – the key is not keeping them a perfect square. Set aside to prep the base.

Make the Sushi Base

If you’ve never made cold process soap before, stop here. We highly recommend checking out our FREE four part SoapQueen.tv series on cold process soapmaking, especially the episode on lye safety. And if you’d rather do some reading, Bramble Berry carries a wide range of books on the topic, including Pure Soapmaking. You can also check out the digital downloads for that instant gratification factor.

FRAGRANCE PREP: Measure 1 ounce of Wasabi Fragrance Oil into a small glass container and set aside.

COLORANT PREP: Disperse 3 teaspoons of the titanium dioxide into 3 tablespoons of sunflower or sweet almond oil (or any other liquid oil). Use a mini mixer to get rid of any clumps.

Optional: To ensure the titanium dioxide blends smoothly into the soap batter, we recommend micronizing it before dispersing it in oil. Use a coffee grinder to break up any clumps of color and prevent streaks of white from showing in the final soap. We like to use a coffee grinder that has a removable stainless steel mixing area for easy cleaning.

SAFETY FIRST: Suit up for safe handling practices. That means goggles, gloves, and long sleeves. Make sure kids, pets, other distractions, and tripping hazards are out of the house or don’t have access to your soaping space. Always soap in a well-ventilated area.

ONE: Slowly and carefully add 2.8 ounces of lye to 6 ounces of water and gently stir until the lye has fully dissolved and the liquid is clear. Set aside to cool. If you’d like a harder bar of soap that releases faster from the mold, you can add sodium lactate to the cooled lye water. Use 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you’d add 1 teaspoon sodium lactate.

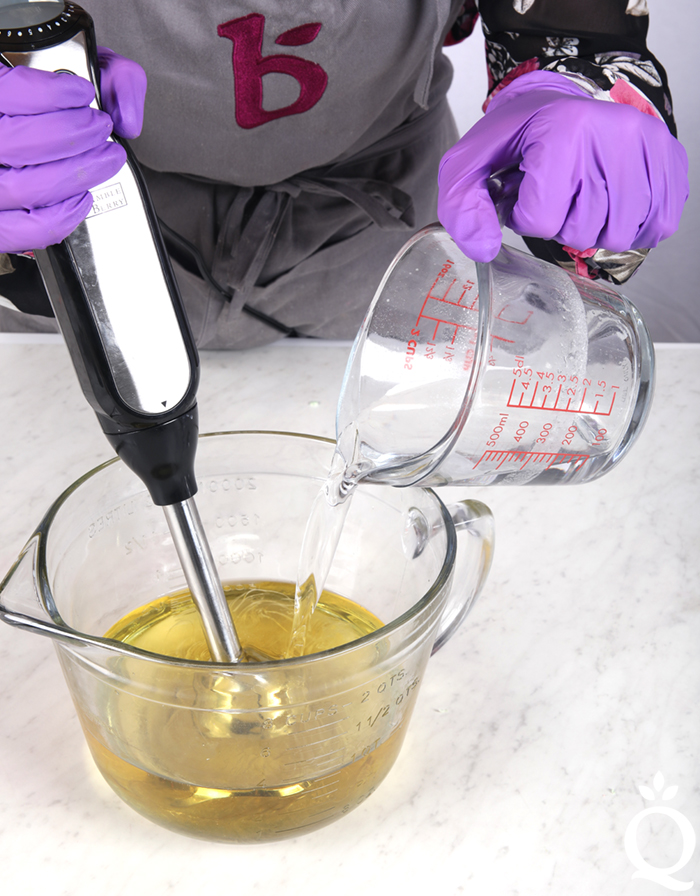

TWO: In a large glass bowl, combine and melt 6 ounces of coconut oil, 4 ounces of rice bran oil, 1 ounce of shea butter, 3 ounces of sweet almond oil, and 6 ounces of palm oil (remember to fully melt then mix your entire container of palm oil before portioning). Once the lye water and the oils have cooled to 130 degrees F or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend the mixture to a thin trace.

THREE: Add all of the dispersed titanium dioxide, and use the stick blender to mix in thoroughly.

THREE: Add all of the dispersed titanium dioxide, and use the stick blender to mix in thoroughly.

FOUR: Add the 1 ounce of Wasabi Fragrance Oil – it will turn bright yellow when it touches the soap batter, but that will fade. If the soap is still quite thin, use the stick blender to mix in the fragrance. If it’s becoming thick, use a whisk to mix it in.

FOUR: Add the 1 ounce of Wasabi Fragrance Oil – it will turn bright yellow when it touches the soap batter, but that will fade. If the soap is still quite thin, use the stick blender to mix in the fragrance. If it’s becoming thick, use a whisk to mix it in.

FIVE: Pour a small amount of the soap into the Silicone Column Mold, and place the embeds in the center in whatever pattern you like.

FIVE: Pour a small amount of the soap into the Silicone Column Mold, and place the embeds in the center in whatever pattern you like.

SIX: Pour (or spoon) the soap into the mold in different areas to help the soap surround the embeds easily.

SIX: Pour (or spoon) the soap into the mold in different areas to help the soap surround the embeds easily.

NOTE: As you can see, our soap got a little thick – we should have used the stick blender less. Aim for a thinner trace than this because it will be easier to pour the soap into the mold rather than spoon it in like we did.

SEVEN: Very carefully tap the mold on the counter to get rid of bubbles. Be careful to not tap the mold too hard, or the airlock can break and the mold can pop open. To prevent this, you can clamp the sides of the mold together.

SEVEN: Very carefully tap the mold on the counter to get rid of bubbles. Be careful to not tap the mold too hard, or the airlock can break and the mold can pop open. To prevent this, you can clamp the sides of the mold together.

EIGHT: Place the mold in the fridge for at least 4 hours. If the soap becomes too hot, it could warp the embeds or the white soap could develop glycerin rivers. Allow the soap to stay in the mold for 1-2 days.

EIGHT: Place the mold in the fridge for at least 4 hours. If the soap becomes too hot, it could warp the embeds or the white soap could develop glycerin rivers. Allow the soap to stay in the mold for 1-2 days.

NINE: Unmold the soap. If the sides of the mold do not peel away easily, give it another day in the mold. Once unmolded, cut the soap into bars. Set them aside while you prepare the nori soap layer.

Make the Outer Layer

COLORANT PREP: Disperse 1 teaspoon of the Black Oxide into 1 tablespoon of sunflower or sweet almond oil (or any other liquid oil). Then disperse 1 teaspoon of Green Chrome Oxide Pigment with 1 tablespoon lightweight liquid oil. Use a mini mixer to get rid of any clumps.

TOOL PREP: We found the Shaving Brush worked wonderfully for applying the black soap to the outside of each bar. If you don’t have one, a large paint brush can work as well. Have a cutting board or sheet of parchment/wax paper to lay each bar on once the soap is applied. You will have plenty of soap leftover, so have a small cavity mold to transfer the leftovers.

SAFETY FIRST: Suit up for safe handling practices. That means goggles, gloves, and long sleeves. Make sure kids, pets, other distractions, and tripping hazards are out of the house or don’t have access to your soaping space. Always soap in a well-ventilated area.

ONE: Slowly and carefully add 1 ounce of lye to 2.1 ounces of distilled water and gently stir until the lye has fully dissolved and the liquid is clear. Set aside to cool.

TWO: In a large glass bowl, combine and melt the 2.1 ounces of coconut oil, 1.4 ounces of rice bran oil, 0.4 ounces of shea butter, 1.1 ounces of sweet almond oil, and 2.1 ounces of palm oil (remember to fully melt then mix your entire container of palm oil before portioning). Once the lye water and the oils have cooled to 130 degrees F or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend the mixture to a thin trace.

THREE: Add 1.5 teaspoons dispersed Black Oxide and 1 teaspoon dispersed Green Chrome Oxide Pigment. Use the stick blender to fully mix in the colorants.

THREE: Add 1.5 teaspoons dispersed Black Oxide and 1 teaspoon dispersed Green Chrome Oxide Pigment. Use the stick blender to fully mix in the colorants.

FOUR: Continue stick blending until you reach a medium trace that holds a peak.

FOUR: Continue stick blending until you reach a medium trace that holds a peak.

FIVE: Using a brush, apply the black soap to the sides of each bar of soap. Use a combination of dabbing motions and brush strokes to create a textured appearance without a lot of the white soap showing through. Place each soap on a cutting board or sheet of parchment/wax paper to harden and dry.

SIX: Continue painting each soap until the outside of each is covered. Work somewhat quickly – the soap will continue to harden as it sits. Transfer the leftover soap batter to an individual cavity mold.

SIX: Continue painting each soap until the outside of each is covered. Work somewhat quickly – the soap will continue to harden as it sits. Transfer the leftover soap batter to an individual cavity mold.

SEVEN: Allow the outside to harden for about 1-2 days before handling. Allow the soaps to cure for 4-6 weeks and enjoy.

- Four Mini Square Silicone Column Molds

- 5 oz. LCP White Melt and Pour Soap Base

- 11 oz. LCP Clear Melt and Pour Soap Base

- Chrome Green Color Block

- Fizzy Lemonade Color Block

- Perfect Orange Color Block

- Fired Up Fuchsia Color Block

- Shimmer Merlot Sparkle Color Block

- Silicone Column Mold

- 6 oz. Coconut Oil (30%)

- 6 oz. Palm Oil (30%)

- 4 oz. Rice Bran Oil (20%)

- 1 oz. Shea Butter (5%)

- 3 oz. Sweet Almond Oil (15%)

- 6 oz. Distilled Water (10% water discount)

- 2.8 oz. Sodium Hydroxide Lye

- 1 oz. Wasabi Fragrance Oil

- Titanium Dioxide

- 2.1 oz. Coconut Oil (30%)

- 2.1 oz. Palm Oil (30%)

- 1.4 oz. Rice Bran Oil (20%)

- 0.4 oz. Shea Butter (5%)

- 1.1 oz. Sweet Almond Oil (15%)

- 1 oz. Sodium Hydroxide Lye

- 2.1 oz. Distilled Water (10% water discount)

- Black Oxide Pigment

- Green Chrome Oxide Pigment

- Optional: Shaving Brush

- Chop 11 ounces of LCP Clear Melt and Pour Soap Base into small uniform pieces. Then, chop 5 ounces of LCP White Melt and Pour Soap Base into small uniform pieces. Add the following amounts of soap base and color blocks to separate, heat-safe containers. Melt the soap and color blocks in the microwave separately using 10-20 second bursts.

- NOTE: If you have fewer than four Mini Square Silicone Column Molds, you’ll need to make the embeds in batches.

Salmon Embed: 3.5 oz. LCP Clear Melt and Pour Soap Base + 0.5 oz. LCP White Soap Base + equal amounts of Perfect Orange Color Block, Fired Up Fuchsia Color Block, and Fizzy Lemonade Color Block + a very small shaving of Shimmer Merlot Sparkle Color Block

Orange Embed: 4 oz. LCP Clear Melt and Pour Soap Base + Perfect Orange Color Block shavings

Green Embed: 3.5 oz. LCP Clear Melt and Pour Soap Base + 0.5 oz. LCP White Soap Base + equal amounts of Fizzy Lemonade Color Block and Chrome Green Color Block shavings

Light Green Embed: 4 oz. LCP White Melt and Pour Soap Base + equal amounts of Fizzy Lemonade Color Block and Chrome Green Color Block shavings - After melting one container of soap, immediately pour it into one of the Mini Square Silicone Column Molds. Place the mold into a sturdy and tall container to make sure the mold stays upright and the soap doesn’t pour out. Repeat until you’ve created all four embeds (green, light green, salmon, and orange). Allow the embeds to fully harden and cool for several hours.

- Remove the embeds from the molds. Trim the sides if necessary – we like using a Clean Up Tool. Use a sharp, non-serrated knife to cut the corners off the embeds as you see fit. We cut one corner off both green embeds and the salmon embed. Then we cut the orange embed into four equal pieces to look like carrots. Don’t worry too much about how you cut the embeds – the key is not keeping them a perfect square. Set aside to prep the base.

- Slowly and carefully add 2.8 ounces of lye to 6 ounces of water and gently stir until the lye has fully dissolved and the liquid is clear. Set aside to cool. If you’d like a harder bar of soap that releases faster from the mold, you can add sodium lactate to the cooled lye water. Use 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you’d add 1 teaspoon sodium lactate.

- In a large glass bowl, combine and melt 6 ounces of coconut oil, 4 ounces of rice bran oil, 1 ounce of shea butter, 3 ounces of sweet almond oil, and 6 ounces of palm oil (remember to fully melt then mix your entire container of palm oil before portioning). Once the lye water and the oils have cooled to 130 degrees F or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend the mixture to a thin trace.

- Add all of the dispersed titanium dioxide, and use the stick blender to mix in thoroughly.

- Add the 1 ounce of Wasabi Fragrance Oil – it will turn bright yellow when it touches the soap batter, but that will fade. If the soap is still quite thin, use the stick blender to mix in the fragrance. If it’s becoming thick, use a whisk to mix it in.

- Pour a small amount of the soap into the Silicone Column Mold, and place the embeds in the center in whatever pattern you like.

- Pour (or spoon) the soap into the mold in different areas to help the soap surround the embeds easily. NOTE: As you can see, our soap got a little thick – we should have used the stick blender less. Aim for a thinner trace than this because it will be easier to pour the soap into the mold rather than spoon it in like we did.

- Very carefully tap the mold on the counter to get rid of bubbles. Be careful to not tap the mold too hard, or the airlock can break and the mold can pop open. To prevent this, you can clamp the sides of the mold together.

- Place the mold in the fridge for at least 4 hours. If the soap becomes too hot, it could warp the embeds or the white soap could develop glycerin rivers. Allow the soap to stay in the mold for 1-2 days.

- Unmold the soap. If the sides of the mold do not peel away easily, give it another day in the mold. Once unmolded, cut the soap into bars. Set them aside while you prepare the nori soap layer.

- Slowly and carefully add 1 ounce of lye to 2.1 ounces of distilled water and gently stir until the lye has fully dissolved and the liquid is clear. Set aside to cool.

- In a large glass bowl, combine and melt the 2.1 ounces of coconut oil, 1.4 ounces of rice bran oil, 0.4 ounces of shea butter, 1.1 ounces of sweet almond oil, and 2.1 ounces of palm oil (remember to fully melt then mix your entire container of palm oil before portioning). Once the lye water and the oils have cooled to 130 degrees F or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend the mixture to a thin trace.

- Add 1.5 teaspoons dispersed Black Oxide and 1 teaspoon dispersed Green Chrome Oxide Pigment. Use the stick blender to fully mix in the colorants.

- Continue stick blending until you reach a medium trace that holds a peak.

- Using a brush, apply the black soap to the sides of each bar of soap. Use a combination of dabbing motions and brush strokes to create a textured appearance without a lot of the white soap showing through. Place each soap on a cutting board or sheet of parchment/wax paper to harden and dry.

- Continue painting each soap until the outside of each is covered. Work somewhat quickly – the soap will continue to harden as it sits. Transfer the leftover soap batter to an individual cavity mold.

- Allow the outside to harden for about 1-2 days before handling. Allow the soaps to cure for 4-6 weeks and enjoy.

Love this soap! Is it possible to make a rimmed soap with this mold ? And if it is , could you have a tutorial of it ?

Since it is a 2 part mold I don’t believe you will be able to make it a rimmed soap. You would have better luck with the heavy duty column mold here: https://www.brambleberry.com/heavy-duty-column-mold-p5401.aspx