Hypothetically, you can make cold process soap with just about any oil or fat. This includes animal fats. The most common animal fats are lard and tallow. Lard is rendered pig fat, while tallow is rendered fat from meat other than pork such as cow, lamb or goat. Tallow and lard are excellent for soapmaking. Both contribute to the firmness of the bar and a stable lather. Lard and tallow are commonly used as palm oil substitutes. If you’re interested in learning more about the benefits of tallow in soapmaking, check out the Understanding Tallow for Soaping guest post.

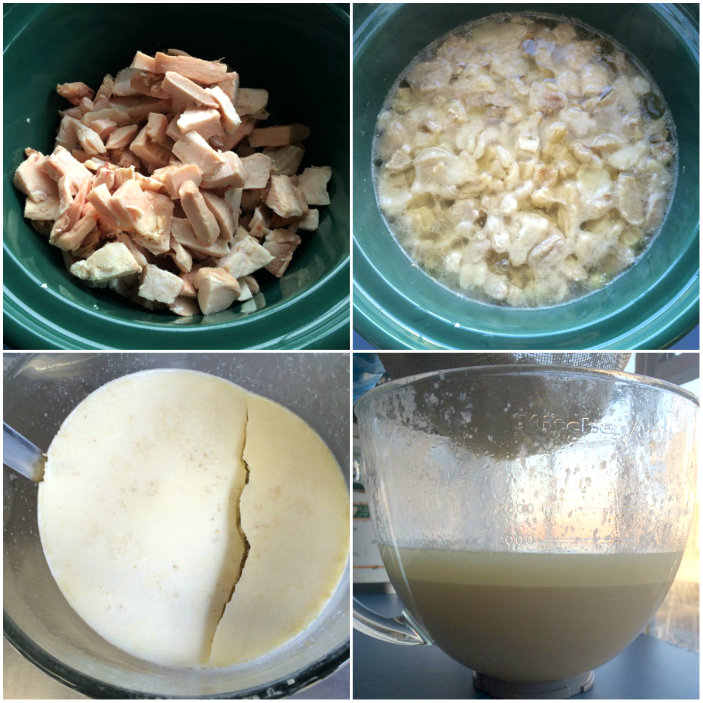

Lard and tallow can be purchased at the store ready to use. Or, you can render your own at home. The basic idea of rendering lard and tallow involves “cooking” the fat along with water. Then, the entire mixture is placed into a container to cool. The fat will rise to the top of the container, while the water will fall to the bottom. This process helps remove any particles within the oil. The process may vary slightly depending on what form the fat is in. For example. if you got your tallow from a butcher, you most likely have chunks of fat and meat that will need to be strained. Our local sister store, Otion, rendered tallow from a local butcher in the Crock-Pot (shown below); click here to see how they did it. They used the rendered tallow to make Mahogany Tallow Soap. This is a topic we’ve touched on before here and here.

Otion Soap Bar recently rendered chunks of tallow in the Crock-Pot for soapmaking, click here to see the process.

Otion Soap Bar recently rendered chunks of tallow in the Crock-Pot for soapmaking, click here to see the process.

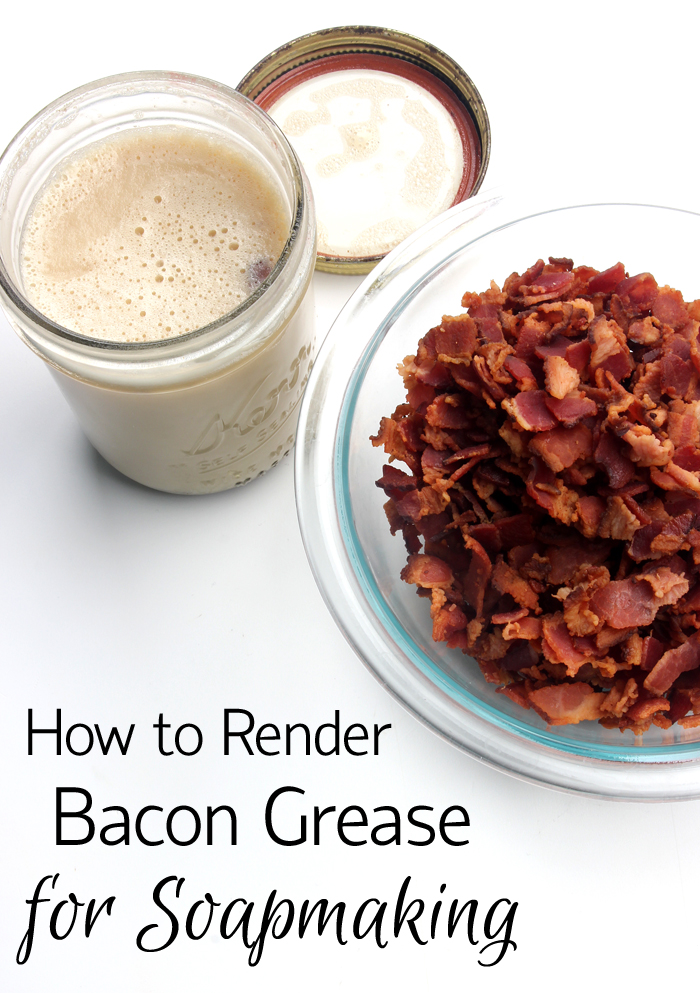

Recently, Bramble Berry hosted a salad bar for the entire team. Included in the bar was bacon, which was cooked by an employee at home. Cooking all that bacon resulted in a lot of bacon grease! Instead of throwing away the grease, we decided to reuse the grease to make soap. First, it needed a little TLC. You can see the lard below. It still had a lot of bacon bits, and was quite smelly.

This bacon grease can be used for soap, but it still has a lot of icky bacon bits inside. It needs to be cleaned up a little. =)

This bacon grease can be used for soap, but it still has a lot of icky bacon bits inside. It needs to be cleaned up a little. =)

To clean up the lard, gently heat the bacon grease and place it into a saucepan. Then add about twice the amount of water. Don’t worry too much about the exact amount of water. Just make sure to not fill your saucepan up too high. You don’t want the pot to boil over (think: bacon grease + hot stove = danger Will Robinson; danger!) . Turn the saucepan on medium heat and allow the pot to come to a slow boil.

Allow the mixture of grease and water to gently boil for about 10-15 minutes. Don’t leave the pot unattended during this process. Eventually the mixture will turn a creamy color once the water and oil begin to mix.

Boiling the grease with water is the first step to remove all those bits and reduce the smell.

Boiling the grease with water is the first step to remove all those bits and reduce the smell.

After about 10-15 minutes, turn off the stove and very carefully pour into a large container. Place the container in the fridge overnight to cool. The grease will rise to the top of the container and the water will fall to the bottom. Notice how icky and brown that water is! This was once in the grease, but the rendering process helps to clean it out.

Remove the hard grease from the top of the bowl, and repeat the process. Place the grease into a sauce pan, add water and allow to slowly boil for about 10 minutes. With each rendering, the grease will become more and more clean. How many times you render the grease will depend on personal preference. I recommend at least three times. I rendered this grease four times, and it still had a bit of a smell, but was not overbearing. Tina who works in our customer service department rendered her bacon grease eight times to obtain a very white, nearly odorless lard.

Once the grease and water have cooled, the lard will rise to the top. Notice all that icky brown water! That was once in the grease.

Once the grease and water have cooled, the lard will rise to the top. Notice all that icky brown water! That was once in the grease.

After rendering my bacon grease four times, I noticed there were still a few “bacon bits” in the grease. To get rid of them, I heated the grease in the microwave and strained it through a tea bag. This filtered all those little bits. Be careful when microwaving the grease. I found out the hard way that 90 seconds in the microwave was way too long, and ended up wiping down the inside of the microwave. ☹ At this point, I was happy with my grease and it was time to make some soap with it. Be on the lookout for that project later this week!

Have you ever used bacon grease to make soap? I would love to hear about your experience!

Can you use goat milk instead of distilled water in this?

Yes, goat milk will work in cold process recipes. We recommend keeping it cold to prevent scorching. Learn more in this post: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-add-lye-to-milk-for-cold-process-soap/

Sounds great! I’ve rendered tallow a few times in my instant pot for soap making and made a batch with chicken fat recently. Bacon grease gets so dirty I’ve honestly never thought about it.

It was fun to experiment, and the bars felt great too – they had a nice creamy texture.

Lard and Loofah Cold Process Soap: https://www.soapqueen.com/bath-and-body-tutorials/lard-loofah-cold-process-soap-tutorial/

My best-selling soap in my shop is actually my ox tallow soap! It’s pure 100% ox tallow, no other oils added. I soap it at 5% superfat and hot process it to help make it less crumbly and easier to cut. Makes a pure white bar that will eventually turn a little yellow with a faint sweet scent on its own. I can’t keep the stuff in stock long enough, it must be the combination of a very short ingredient list and no fragrance.

That’s awesome, sounds like it’s a simple recipe that’s effective.

I went on ketogenic lifestyle which included lots of bacon. Although I lost 50 pounds in 2 months, and ended up saving much of my lost fat as bacon grease without knowing what I was saving it for =]. Can’t wait to try this out. Also, in the process of saving my fat, I used a metal coffee filter to remove particles from the grease and was able to store numerous jars of clean/creamy looking fat. BTW, 2 years later, the weight is still off.

Absolutely, this is a great use for those leftovers. Also, congratulations on your hard work. 🙂

I make bone broth from beef bones quite regularly; I skim off the fat from the broth and either use it for cooking or throw it out. Is there a way that I could use that to make soap? How would I make sure to get the right lye calculation with it?

I believe that the fat created by making beef bone broth is used the same way as tallow from other parts of the animal. Like shown in this tutorial, the fat will need to be cleaned before using it in soap. When calculating your recipe, select the “Tallow” option in the lye calculator.

Lye Calculator: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

-Amanda with Bramble Berry

Is it possible to make candles from lard?

We haven’t tried that, so I’m not entirely sure. My worry is that the fat would start to smoke as the candle burns down, and it may also affect the scent. You may check teachsoap.com/forum to see if someone has a recipe or tips for creating lard candles.

-Kelsey with Bramble Berry

i have a question, do you think this process can be used to refine raw shea butter? i filtered, but there is stil a lot of “dirt” i tried this process and it volcanoed, i thought i was going to start a fire! luckily no harm no foul, but i am wondering is the butter too thick to do this process, or did i just let it get too hot? i stoped stiring for one second and kaboom there it went. I will try in the crock pot this time, maybe it will be more controlled.

We haven’t tried refining shea butter, so I’m not entirely sure. You may check teachsoap.com/forum to see if someone there knows more.

You may also like the refined shea butter available on BrambleBerry.com: https://www.brambleberry.com/Shea-Butter-P3220.aspx

-Kelsey with Bramble Berry

Hi Everyone,

I’ve boiled my used bacon grease and now there is a lot of water emulsified in the grease. Is this normal or did I do something wrong? Do I need to remove the water from the grease before making soap? If i don’t remove the water, will the water impact my water to lye ratio?

Thank you!

Hi Bryan! The water acts like a filter when you’re rendering the fat. So, when you add water, it grabs onto all the particles and removes them. So, you remove the fat, add clean water and repeat the process. That will clean the fat. At the end, the water should separate so you can remove the fat. If you find the water has mixed in, boil again, let it cool and remove the fat so there isn’t any water in it. 🙂

-Kelsey with Bramble Berry

Thank you, Kelsey for clearing that up for me.

Have a great week.

Help! My husband has been boiling & separating our first batch of bacon grease at his restaurant, and it’s gone just fine. Brought the grease home yesterday, and boiled it with water one more time…went perfectly. Tried it again with fresh water this morning, and KABLAMO! It went from warm with a completely smooth surface, to some sort of awful volcanic eruption, all of a sudden. I did exactly the same thing as yesterday, with a completely different result. What causes this, and how can I fix it? Want to get rid of as much bacon smell as possible, without trashing or setting fire to the kitchen.

Hmm, I’m not entirely sure why that’s happening! How many times have you rendered the fat?

-Kelsey with Bramble Berry

He boiled 6 times at the restaurant, and it worked perfectly. He brought it home, where I boiled it twice more – first time was perfect, second time was scary.

The more the fat is boiled, the more the fatty acid chains inside start to break down and oxidize. That means the fat can heat up more easily than the first time it boils. I think that’s the reason for the eruption! The good news is that fat should be fine and ready to use for soap. 🙂

-Kelsey with Bramble Berry

Ah-HA!! Ok, that makes sense. It made some wonderful soap! 🙂

So glad to hear that! There’s nothing better than a bar of handmade soap. 🙂

-Kelsey with Bramble Berry

For anyone reading this and having the same problem, this happens when the oil reaches the bottom of the pan or there is too little water, and obviously can be very dangerous. It has nothing to do with the breakdown of fatty acids, which is irrelevant to the situation regardless of whether or not it occurs (at 212°F, it’s not). Any mixture put to heat, methanol, ethanol, water, glycerol, fat, is limited in the temperature it can reach under any given pressure by the boiling point of its constituent with *the lowest* boiling point. So, as long as you have enough water in the mix, enough to float the oil off the bottom of the pot, your oil/water mixture will never get hotter than 212°F. No matter how much heat you apply, you will only cause the water to boil faster, which will, in turn, cause a greater cooling effect. This dynamic changes once you’re almost out of water. The water no longer produces enough steam to continually break up the surface of the oil, and little pockets get trapped inside the more viscous oil, in which they are totally immiscible. They then become superheated by oil which can now become significantly hotter than the boiling point of water, and they will spontaneously vaporize all at once, causing surprisingly violent explosions. So if you don’t want to make an unholy mess in your kitchen, or worse, receive a face-full of boiling oil, make sure that you either a) always have enough water, or b) keep the mixture below 212°F by either putting it in the oven, or making use of a double boiler to regulate the temperature.

Thanks so much for sharing your tips!

-Kelsey with Bramble Berry

What a fantastic bit of information! Love that you were willing to share your knowledge for free! Thank you – I quite enjoyed learning from you today!

I keep bookmarking helpful articles on CP soapmaking. Pretty soon I will have bookmarked your entire site. It’s like falling down a Wikipedia rabbit hole.

I would like to know… what’s the shelf life of clean bacon lard? Does the cleaning process help make more shelf stable? This sounds like a great, economical idea to reuse various greases and store them in bulk, as long as they last long enough to be used.

Personally, I wouldn’t mind smelling like bacon after taking a shower, but it’s great to know how easy it is to “clean up” my grease to use when we run out of palm oil.

Thank you so much Phil, glad you’re finding the blog helpful!

Lard should last about a year. After that time it can go rancid. To help it last longer, we recommend storing it in a cool, dry place. You can keep it in the fridge as well. Read more about storing products here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-store-handmade-bath-products/

I think the rendering process can extend that shelf life a bit! It helps remove impurities and any leftover bits of bacon that can go rancid in the mix. 🙂

-Kelsey with Bramble Berry

Thanks for sharing how to render these fats. I always wondered how they got the smell out. I have a very sensitive nose and have no interest in wearing the smell of animal fats on my person. And I have been very interested in trying tallow, but have not been able to find it for sale anywhere.

You’re welcome Irene! The more you render the fat, the more faint the smell will be. You can also use a smaller amount in the recipe (around 10%). You can also use a nice strong scent in the bars, like peppermint essential oil. That can help cover up some of the scent. 🙂

Peppermint essential oil, 1st distill: https://www.brambleberry.com/Peppermint-Essential-Oil-1st-Distill-P3828.aspx

-Kelsey with Bramble Berry

Actually I made a bacon fat & beer soap for a friend. I think it came out quite well if I do say so myself 🙂

That sounds like an awesome combination! I bet your friend loved it. 🙂

-Kelsey with Bramble Berry

I render my own locally-sourced organic tallow – 20 lbs at a time. I use a Nesco roaster set at 275. I add about 4-6 cups of water and let it go about 24 hours in the garage, stirring occasionally. I strain and put the remenants into a small pot and render further with more water so it doesn’t brown.

I get beautiful creamy tallow, the slight smell disappears during saponification. Makes an amazing soap and Italian cream shaving soap.

That’s awesome Amanda, thank you for the great tips! I love the creamy feeling of tallow in soap. 🙂

-Kelsey with Bramble Berry

I do this all the time. I actually clean any fat that I get from cooking and/processing: pork, beef, chicken, lamb, goat, etc. I clean it all as you detail and use it as soon as I gather enough for a batch or two. We raise and process our own meats and have our own dairy goats (I only make goat’s milk soaps), so I know all of my ingredients are clean and pure with no additives or antibiotics. It’s also a great way to eliminate waste and use every little bit available. We use other oils too for our commercial line (animal fat doesn’t sit well with everyone), but a pure lard soap makes a great laundry bar.

I didn’t think to add it to my original post, but I actually have a batch boiling on the stove right now.

Does this need to be kept refrigerated or stored differently from plant based oils? Or do you really just need to use it right away?

For what my two cents are worth, I pressure can or freeze mine after cleaning (you can also freeze prior to cleaning) so there are no worries about rancidity, or I try to use it within a week or two. It will keep longer than that in the fridge, but I never seem to have enough room in there.

Laura has some great tips! For storage, we recommend a cool, dry place like a basement, cabinet or fridge. In the fridge, it should keep for about 6 months, and in the freezer about 6-9. 🙂

-Kelsey with Bramble Berry

Thanks for doing this. Animal fats are a much more eco-friendly fat than tropical oils like Palm. The fats are often discarded as a waste product. Using them keeps them out of a landfill and requires next to no transporting, unlike palm which is very bad for the environment and animals, and requires shipping for thousands of miles.

Anyway, it was interesting to see how to clean up bacon grease. I’ve never tried that. I usually use lard from the small farm up the street from me. Maybe I’ll try bacon grease, too. Thanks.

You’re welcome Jennifer! We love the idea of nothing going to waste. It’s a bonus that the soap feels nice and creamy too. Hope you get a chance to try bacon soap! 🙂

-Kelsey with Bramble Berry

This is a cool idea…i might be trying it

Have fun and let us know how it goes! 🙂

-Kelsey with Bramble Berry

Hy there! Thank You for sharing this story! I must say this was a common way to make soap in my country (Croatia). Rural women made soap from lard for hundreds of years. My grandmother used to do it very often. This kind of soap is unrepleaceble for clothes washing. It was traditionaly used for washing linen traditional clothes. Removes every kind of stain especially hard ones. I use it still in prewash for removing stains from grass, motor oils etc. Just rub on a stain and put it in a washing machine as usual. The bar of soap is hard, bubbly with large bubbles and the lather is consistent. The soap does not have any bacon smell at all. It is cremy white. Although tha lard is made in a bit different way ( bacon is chopped and put on a low heat to melt itself without water. It takes some more time. When it ‘s melted it is set for a while for the chunks and bits fall to the bottom than it is strained and used for cooking or soapmaking). Well, this is a traditional, indigent way of soap making in Croatia!

Oh that is so awesome Ivana, thank you so much for sharing! As someone who spills a lot of things on clothing, I’ll definitely have to try bacon soap on stains. Great tips. 🙂

-Kelsey with Bramble Berry

That’s very interesting, Ivana. Thank you for sharing. I know pioneer women in this country used to make their own soap too, but I never quite knew how it was done. Someone on You Tube was sharing that their grandmother added soda, salt, and sugar to her soap recipe. It is so intriguing to hear how our ancestors used to do these things.

I rendered sheep fat for soap making. My process: cut off as much meat from the fat as you can, grind it up (melts faster this way), I added no water to the pot. Cooked it on the most gentle slow heat till it was all liquid and boiling, used a kitchen scoop to remove the obvious chunky bits. Then using a folded muslin cloth, strained it and poured it into clean sterile jars. It made a pure white hard fat, that smelled faintly of lamb chops but it didn’t bother me. Used the BB lye calculator and made soap. It’s come out beautifully, I couldn’t be happier. I use it as my laundry and dish soap. I didn’t want to waste money on expensive oils for this soap so the tallow is a great option. I only rendered it once and it was fine to use, no impurities and no need to add water.

Thank you for sharing your awesome tips Suzie! What a great way to use that sheep fat. I love handmade laundry soap, I’ll have to give tallow or lard a try. 🙂

-Kelsey with Bramble Berry

OK, you asked about my experience making bacon grease soap and I do have one, but I used beef tallow instead. I’ve made hundreds of batches of soap and that’s the only one I had to throw away. I only boiled it once, but the tallow seemed white and firm. I used the lye calculator and proceeded as usual. I knew something was wrong when I had a difficult time getting it to trace. There was still oil floating on top, but I continued and eventually poured it. The next day, the soap was hard, brittle and crumbled apart. I did not want to try it so I threw it out. I may try this again and render it a bit longer and maybe lard instead of tallow. I just wanted to see what tallow soap was like because I have made soap with store purchased lard. Excellent article as always!! Thanks a million to all of you once again!!!!!!!

You’re very welcome James, glad you love the post! I think rendering it a few more times will really help. That helps get rid of any parts of the tallow that won’t saponify and do weird things in your soap. 🙂

-Kelsey with Bramble Berry

What is the ratio? How much fat will result in how much “clean” tallow/lard? Sounds like an interesting process, but I don’t see myself using animal products in soap.

Hi Michael!

During this process, we did find that with each “cleaning” of the bacon grease, some was lost. When the grease and water are placed in the fridge/freezer to cool, the grease will rise to the top. When you separate the grease from the top, small bits of the grease will tend to stay in the water. If you’re really trying to save every little bit, you could use a small strainer to try to get some of the bits, but this may be more trouble than it’s worth :). We also had a little snafu with reheating the grease in the microwave; it overheated and exploded…so a decent portion of the grease didn’t make it because of this. Oops, lesson learned there!

I would estimate you will loose about 25% of the grease during the process if being careful. I would recommend formulating your recipe size based on how much grease you have after the cleaning process, not before. That way if you loose more than planned, you are not short on your recipe 🙂

-Amanda with Bramble Berry

Perfect thanks! Can you make soap with vegetable shortening?

You can! Vegetable shortening has a similar feeling to lard – it’s a bit softer, but still solid at room temperature. I would recommend adding it around 30% to start with. Also, keep in mind the ingredients in vegetable shortening change depending on what’s available. For instance, one batch may have more soybean, etc. Before making soap with new vegetable shortening, I would recommend a small test batch to see how it feels. 🙂

-Kelsey with Bramble Berry

I have done this – it’s a lot of work, but it’s fun. I was selling several bars at a time to guys – I don’t know what they used it for, but a couple of them were repeat customers. I didn’t render mine bunches, so it still smelled a bit like bacon, but who doesn’t love the smell of bacon??

My brother is a bacon fanatic…I so need to make him some bacon soap…leave a little of the smell in there 🙂

I like the smell of bacon from afar, but I wouldn’t want to be wearing it…

That’s awesome! The idea of bacon soap is so fun. It actually creates a really nice creamy lather too. 🙂

-Kelsey with Bramble Berry