Water and lye are crucial components of cold process soap. Water is used to dissolve the sodium hydroxide lye so it can interact with the soaping oils to begin the saponification process. As the soap cures, some of the water evaporates and makes a harder, longer-lasting bar of soap. How much water you use in your soap will depend on the calculator you use. You may also choose to “water discount” the recipe and use less than what is called for. If you’re unfamiliar with how the saponification process works, click here to learn more about the balance of lye and oils.

Using less water than originally called for in a recipe is known as a “water discount.” There are several reasons why you may want to water discount soap. Water discounting helps the soap release from the mold faster. Using less water also results in a shorter curing and drying time, as there is less water to evaporate from the soap. Soapers may also choose to water discount if the recipe contains additives that naturally contain water, like fruit or vegetable purees. Using less water can reduce the chance of soda ash and glycerin rivers. In addition, water discounting affects the temperature at which soap goes through gel phase. Water discounting has plenty of benefits.

Water discounting is a great way to avoid glycerin rivers (shown above). Learn more about how to avoid glycerin rivers here.

Water discounting is a great way to avoid glycerin rivers (shown above). Learn more about how to avoid glycerin rivers here.

You may be thinking, “If there are so many great reasons to water discount, why don’t soapers do it all the time?” Some soapers do choose to water discount with every recipe. The trick is that water discounting a soap recipe can cause the soap batter to thicken quickly. Generally, the more a recipe is water discounted, the faster the soap thickens. This is because the lye solution is more concentrated, which speeds along the emulsification process. The water content also affects when soap goes through gel phase and how it reacts to heat. A fantastic (and beautiful!) demonstration of this is shown in The Ghost Swirl by Clara of Auntie Clara’s Handcrafted Cosmetics. In this post, Clara demonstrates wonderfully how soap is affected by water content.

Because a water discount causes the soap to accelerate faster, water discounts can make a recipe difficult to work with. If your recipe contains a large amount of hard oils or an accelerating fragrance oil, you may want to avoid water discounts. I generally recommend water discounting for more advanced soapers who are prepared to work with a faster moving trace. If you’re looking for more information, the All About the Trace post is full of tips and photo examples of thin vs. thick trace.

Water discounting a recipe can cause the soap to accelerate, resulting in a thick trace.

Water discounting a recipe can cause the soap to accelerate, resulting in a thick trace.

Technically, there is not an “absolutely correct” amount of water to use in your soap recipe. In fact, if you plug in your recipe of soap making oils into various lye calculators, you may end up with slightly different amounts. Water is roughly 22% of the total recipe (oils + lye + water) when calculated with the Bramble Berry Lye Calculator. Other lye/soap calculators may give a slightly higher or lower amount. The amount of water in a recipe is determined by the amount of lye, not the amount of oils in your recipe.

The important part of determining how much water to use in your recipe depends on the ratio of lye to water you prefer. Remember, the lye solution is created by dissolving and diluting lye into distilled water. A common dilution rate is 30% lye and 70% water. In other words, the total makeup of the lye mixture is 1 part lye to 2.3 parts water. When the ratio of lye to water increases, the mixture is more lye concentrated. For example, a solution with 40% lye and 60% water (with a ratio of 1 part lye to 1.5 parts water) is more highly concentrated, because it contains less water in the total mixture.

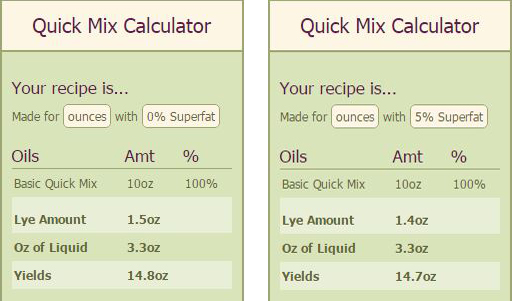

The Bramble Berry Lye Calculator produces lye and water mixtures with a ratio of roughly 1 part lye to 2.4 parts water. This ratio will change slightly depending on the superfat percentage of your recipe. For example, let’s take a look at two similar recipes for the Basic Quick Mix. Both recipes contain 10 ounces of oils. One has a superfat of 5% (shown on the right) and the other has a superfat of 0% (shown on the left). As you can see below, the water amount stays the same. But, the ratio of water to lye changes slightly; the soap with a 0% superfat has a ratio of 1 part lye to 2.2 parts water, while the soap with the 5% superfat has a ratio of 1 part lye to 2.4 parts water. Soap with a higher superfat has a less concentrated lye mixture than soap with a lower superfat.

You’ll notice that in this example, the amount of water actually stays the same. This example is technically not a water discount; when you use a higher superfat in your recipe you are actually calculating a lye discount! Kinda cool right?

The lye to water ratio of the lye solution will depend slightly on the superfat percentage of your recipe.

The lye to water ratio of the lye solution will depend slightly on the superfat percentage of your recipe.

Some soapers prefer to not use the water amount given by lye calculators at all! For example, Amanda of Lovin’ Soap Studio prefers to double the amount of lye in her recipe to get the water amount. Read more about her water calculation here. How much water you choose to use in your recipe depends on personal preference, in addition to the oils, fragrance, colorants and additives in the recipe.

If you have decided that you’d like to water discount your soap recipe, there are a few ways to go about it. Let’s take a look at the recipe below from the Creamy Orange Cold Process Tutorial:

13.6 oz. Olive Oil (40%)

8.5 oz. Palm Oil (25%)

8.5 oz. Coconut Oil (25%)

3.4 oz. Cocoa Butter (10%)

4.8 oz. Sodium Hydroxide Lye

11.2 oz. Distilled Water

2 oz. 10X Orange Essential Oil

If you are looking at the total weight of this recipe (oils + water + lye), the water makes up 22% of the recipe. The lye to water ratio of the lye solution is roughly 1 part lye to 2.3 parts water. This is equivalent to roughly 30% lye and 70% water. Let’s do a water discount of 10%. Ninety percent of 11.2 is 10.08 (11.2 x .9 = 10.08). We can round this up to 10.1 oz. to make it easier to measure. This is the new water amount for your recipe. The amount of lye will stay the same. Remember, when you decrease the amount of lye, you are creating a lye discount which will increase the superfat of your soap. The lye and water solution will now have a ratio of 1 part lye to 2.1 parts water. Or, the mixture is now 32% lye and 67% water. This seems like a small change, but it can make a big difference.

It is possible to water discount too much. If your solution contains too much lye and not enough water, the mixture can become extremely hot and very, very dangerous. In addition, the lye may not have enough water to dissolve fully. In general, the absolute highest ratio of water to lye is 1:1. This means there is equal parts lye and water in the mixture, or 50/50. At this ratio, the lye is still able to dissolve, but will be very concentrated and somewhat difficult to work with. I do not recommend this ratio of water to lye. Some advanced soapers use a ratio of 40% lye to 60% water, but this is still an extremely concentrated solution, and may be very difficult to work with.

So, when should you water discount your soap? Technically, you can water discount any batch you’d like! Just be prepared to move quickly. You may want to have a backup plan if the soap becomes too thick. If you’re adding ingredients that give the recipe additional water (like purees) that’s also a good reason to do a water discount.

In the Pumpkin Spice Swirl Soap, pumpkin puree is added which gives the recipe extra water. A 15% water discount prevented the recipe from containing too much water.

In the Pumpkin Spice Swirl Soap, pumpkin puree is added which gives the recipe extra water. A 15% water discount prevented the recipe from containing too much water.

A great example of water discounting a recipe to account for water-filled additives is the Pumpkin Spice Swirl Cold Process Soap. This recipe contains 2.5 oz of pumpkin puree, which contains water. It’s tricky to know for sure just how much of the puree is comprised of water, so it’s a bit of a guessing game. I went with a 15% water discount, which gave me a ratio of about 1 part lye to 2.1 parts water. I could have done a little bit of a steeper discount, but I wanted to make sure I had time to swirl. How much you water discount depends so much on your recipe, personal preference and comfort level.

If you have never worked with a water discount before, I would recommend starting with a 10% discount. This is a good starting point that you can increase once you get the feel for how your recipe behaves with a more lye concentrated solution. I would also recommend keeping your design fairly simple just in case! Layers are a good design option for experimenting with water discounting, because thick trace will help keep the layers separate. I rarely go above a 15% water discount; the only time I do is if I need my soap in a hurry and want to cut down on the drying time. =)

Just to summarize, below are some pros and cons for water discounting your soap –

Pros of Water Discounting:

- Generally, the soap will be able to be removed from the mold faster.

- Reduced water in the recipe cuts down on the 4-6 week cure time of cold process soap.

- Less water can prevent glycerin rivers from occurring. This is particularly helpful if your recipe contains a large amount of titanium dioxide, or will become extremely hot. Click here to read more about what causes glycerin rivers and how to prevent them.

- Water discounting your recipe can help prevent soda ash. Click here to read more about soda ash, including how to prevent it.

Cons of Water Discounting:

- Water discounting can accelerate trace, which can result in very thick soap batter. Click here for more information on trace.

- If your soap accelerates, it can make some complicated soap designs like swirls difficult to execute.

- Water discounting can make it more difficult to work with accelerating fragrance oils. Read more about working with accelerating fragrance oils here.

- Soap with a lower water content requires higher temperatures to go through a full gel phase. If you like your soap to go through a complete gel phase, water discounting makes this a little more difficult. See a beautiful example of this in The Ghost Swirl by Auntie Clara’s Handcrafted Cosmetics.

Do you water discount your cold process recipes? I would love to hear about your methods for discounting! It depends so much on personal preference, and I’m interested to know what works for you, and what doesn’t.

Great article, I recently flubbed up with my calculations and discounted my water by 1.1 ounce with a 49 ounce batch of oils. I was worried until I read this article. I’m happy to know that the soap will be safe to use, since it was intended for babies. I’m new to this and have only been making soap for 10 months. Thanks for clearing my mind.

Absolutely, it’s an accidental water discount! That soap will harden and unmold more quickly. 🙂

-Kelsey with Bramble Berry

Thanks for the beautiful lesson. Please, I just want to have a rough idea of the ratio in weight of raw materials used to ratio in weight of soap obtained assuming no other source of water such as fruit puree or liquid plant extract is used. This is so I might know if soap making is a profitable venture – all other local factors considered.

Just to clarify, you want to know the ratio of oils, water, and lye?

-Kelsey with Bramble Berry

Hi Anne-Marie,

Many many thanks and I love you for your posts. I’m a new soaper, and just wanted to know if I can use more water than is prescribed by the Brambleberry lye calculator. I mostly use quite a few hard oils, so end up getting to thick trace very fast. Can I use excess water to keep my soaps workable for intricate designs?

Thanks again.

You can, that will help slow things down a bit. You will need to cure the soap another week or so to ensure all the water evaporates. Get more tips for slowing down that soap here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/five-tips-swirling-cold-process-soap/

-Kelsey with Bramble Berry

Many thanks, Kelsie. Will work on these and share my results with you.

Sounds good!

-Kelsey with Bramble Berry

I am a new soaper and I am wondering something about water discounting. When I use the lye calculator and it tells me how much lye and water to mix together, is that considered 0% water discounting or is there already an automatic water discount calculated in and how do I know what it is just by looking at a recipe? Is there a way to look at a recipe and know if it has already been discounted before I make any new calculations? Or is a water discount something you do after the recipe has already been written? I hope those questions makes sense! Thank u

That is correct – the Lye Calculator will always give you the 100% liquid amount with no water discount. There’s not an easy way to tell if a recipe has a water discount. The best way is to enter it into the Lye Calculator to see if the liquid amounts are different. We also say on all our recipes if there’s a discount and how much to make it easier. 🙂

-Kelsey with Bramble Berry

Lye Calculator: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

Just wanted to note that I began using a water discount as a way to prevent over heating in my soap molds – I was having cracking consistently on the top in my wood molds, and when I use less water the heat cycle during saponification is much more predictable.

That’s awesome, another benefit of a water discount! 🙂

-Kelsey with Bramble Berry

I am starting to have a headache from reading so much on water discounting. From what I figure soapers usually water discount when they want to reduce curing time and also if adding an alternative liquid. I want to add an alternative liquid. You advice in general to water discount at 10-15%. I want to add tomato puree and carrot puree for separate soaps. Do I take the equivalent of say 10% of my total water content in grams or oz and replace this with carrot puree or tomato puree? Or I can go higher? If higher how much so?

Also tomato soap recipes I find online says you can replace all the water called for in a recipe with tomato puree, is this advisable? Thank you as you reply.

Water discounting can be tricky at first. However, there is a way to simplify it. Do you want to add tomato/carrot puree at trace, or use juice in place of the liquid? Let me know and I can offer some tips.

-Kelsey with Bramble Berry

Hi there! I’m not sure if someone already asked this question.

Does water discounting help for a denser bar of soap? Heavier and perhaps longer lasting?

Because, do you end up using more oils say to reach a 10lb goal, since you’re using less water, do you have to make up for it with oils? Thank you!

Water discounting doesn’t change the feel of the soap too much. It does help the soap unmold and cure more quickly, which is helpful if you’re short on time. As the soap cures, the excess water evaporates. That means bars with and without water discounts will eventually weigh a similar amount, but one with a water discount will evaporate more quickly. If you planning on discounting a large amount, your soap will weigh less initially. So, you can plug in a larger batch in the Lye Calculator for your mold: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

-Kelsey with Bramble Berry

Hello there, thank you for all your information.

How much water (%) does cp soap loose during the curing periode and how can I measure this.

I know that the weight loss (depending of your formula) is about 7-15&, but what does this say about the water: Thanks again.

It’s hard to say exactly how much water your bars lose as they cure. It depends on how much water you add initially, how humid your climate is, etc. I would recommend making a test batch and weighing right after they’re cut, then weighing again once they’re fully cured. That will give you an idea of how much water loss to expect. 🙂

-Kelsey with Bramble Berry

I am wondering how to remedy the situation when you accidentally measure wrong and discount way too much. My scale was having issues, so when I measured out my goats milk it didn’t look like enough. But since it was my first time making goats milk and honey soap, I didn’t think anything of it. When I added my lye to the milk, the lye never seemed to dissolve, but I again thought maybe it was the milk. I added it to my oils and it thickened so fast, it instantly looked like refried beans. I hurried and plopped it into the mold, but it’s now super crumbly and ugly. Can I save it? The milk is not scorched, but I’m afraid that there might be loose lye crystals in there. ( I’ve since made a successful batch, where I realized my mistake of too little milk/liquid) I’m hoping there’s a way to save that first batch. Thanks!!

I would recommend pH testing your soap. You want it to be around 9-10 pH. If it’s higher than that, it is lye heavy. Make sure to test a few areas to make sure there are no lye pockets. Learn how to pH test here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

If the soap is lye heavy, you can use it for laundry soap! However, if there are pockets of lye, we recommend throwing it out. Those can burn or irritate the skin.

If it’s not lye heavy, you can still use it for laundry soap or rebatch it. Rebatching it with equal parts of a soft recipe can help make the bar more balanced. 🙂

Learn more about rebatching here: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/soap-queen-tv-presents-how-to-make-rebatch-soap-2/

Our Castile Rebatch is nice and soft: https://www.brambleberry.com/Grated-Rebatch-Soap-Base-Castile-P5233.aspx

-Kelsey with Bramble Berry

I’m a little confused. In your lye calculator it seems like it’s a 33% water. At least when I ran it through another calc that’s what came up.

So do you recommend for beginners just 33% or 38% like other calculators say? It seems to me that the soap doesn’t set up well for beginners at 38%. Any suggestions?

Thanks!!

Our Lye Calculator is calculated with the SAP values from our oils, so it may be a bit different than other calculators. We find the 33% works well. It dissolves the lye and gives you time to work with your design without making the soap too wet. 🙂

-Kelsey with Bramble Berry

Lye Calculator: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

If you are water discounting can you lye discount as well?

You can! Most of our recipes have a lye discount (superfat) of 5%. It adds some extra luxury to the bars. 🙂

Read more about superfatting here: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/superfatting-soap-an-explanation-2/

Our Lye Calculator automatically calculates that lye discount for you: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

-Kelsey with Bramble Berry

Thank you! Does the lye need to be less if water discounting (regardless of the superdat discount)?

It doesn’t! The lye amount will remain the same with water discounting. 🙂

-Kelsey with Bramble Berry

So discount 10% of the 21.1oz water I regularly us? TIA 🙂

That is correct! The easiest way to find that is to multiply 21.1x.9 (90%) to get the 10% discount. 🙂

-Kelsey with Bramble Berry

If someone water discounts 10-15%, how much actual time will that save on the 4-6 week curing time? Newbie

How much cure time will depend on the recipe, your environment, etc. I would imagine it would shave at least 3-5 days off, probably closer to a week. To speed that process up even more, make sure your soap cures in a cool, dry place. If you have a dehumidifier that will help too! 🙂

Read more about storing and curing soap here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-store-handmade-bath-products/

-Kelsey with Bramble Berry

Thank you!!!!! 😊

You’re welcome! 🙂

Hi thanks a ton for this article. Am a new cp soaper and though have 4 batches under my belt, am still learning everyday. Your article helped me understand water discounting, though I haven’t done that yet. Will bookmark this for future references 🙂

In fact I keep coming here everyday for tips and information😜 Was reading about your article on using sodium lactate to increase soap hardness and found the link for this article there.

Thanks for all the guidance and help 🤗

You’re very welcome! So glad the posts are helpful for you. If you have any questions let us know, we’re happy to help. 🙂

-Kelsey with Bramble Berry

Hello 🙂

Is it possible to discount 50% of the water and add this back after emulsification in order to incorporate things like carrot juice or pomegranate juice for example ?

Hi Hila!

You can discount 50% of the water! You just want to make sure the lye dissolves fully. Make sure it’s completely clear after stirring, you can add more distilled water. Also, with the discounted water and the natural sugar in carrot and pomegranate juice, the soap will accelerate a bit faster than normal. I would recommend soaping at lower temperatures (around 100F) and being prepared to work fast! Then, you can pop the soap in the freezer for 5-24 hours to prevent any overheating. 🙂

-Kelsey with Bramble Berry

Hi, I am new to CP soapping, and I have a question. Let’s say my lye calculations is 4.91 Oz and my water is 13.68oz. What I have been doing is keeping lye the same amount but changing the water less 5 Oz and adding 5oz of aloe Vera juice to the distilled water and lye. Is that OK to do? And if so is that still doing a water discount, and will it cure a bit faster. Sorry if this is a dumb question, still trying to figure this soap making process out.

Thank you

Hi Corinne!

That is absolutely fine to do! You can replace part or all of the water with an alternative liquid like aloe vera liquid. It will require the same cure time, as you are adding the same amount of liquid back in the bars If you like, you can water discount by 10% or so to help the bars cure a bit faster. So, 13.68 x .9 (90%) is 12.31 ounces. 🙂

-Kelsey with Bramble Berry

Thank you so much! 🙂

You’re welcome! 🙂

What a wonderful article! This will be a great reference to send people to. Thank you! <3

Thanks so much Amanda! That means a lot coming from you. 🙂

-Kelsey with Bramble Berry

Thank you for the link to Lovin Soap Studio’s article!

I have made all of my CP soap using the Bramble Berry Recipe Maker, but I made a batch tonight using a lye calculator that I hadn’t used before, which provided ranges rather than specific amounts. Note: I opted for this in the calculator. I’m a rookie at this CP soap making, but I know I won’t get better unless I try new things and be open to learning from mistakes…

During the soaping session I noticed things I hadn’t experienced before: hotter lye solution (peaked at 190 F), stronger fumes, faster trace. I molded it all up then decided to run the recipe back thru Bramble Berry’s calculator only to find that it quoted more water (430.65 grams to the 366.2 that I used in my recipe)! I started to panic thinking that I had totally lost the batch (which would have been sad because it smelled so great — Yuzu and Cybilla FO). It didn’t help that when I went back to the calculator I had used for my recipe and retried my calcs again (attempting to reverse-engineer a bit to figure out where I went wrong), it gave me a warning that my soap may not be safe! Ack!

After a good 2 hours reading and searching online, I found this link about doubling the water to lye which is exactly what the 366.2 represented! Whew! All of the heat and acceleration makes sense now and I’m super-duper looking forward to unmolding this soap as soon as it will let me.

Thanks, Amanda, for posting about water discounting and your method for calculations. Thanks Bramble Berry, for supporting such a cooperative information community!

You’re welcome Rachel! Not only is your batch not lost, it will unmold and cure faster thanks to the water discount. 🙂

-Kelsey with Bramble Berry

Hi..

So, since water discount makes the soap hotter, it means EO will get to flash point faster right?

Hi Mac!

In Auntie Clara’s experiments, she found water discounting can actually make it more difficult to go through gel phase because the soap is a bit more cool. If you’d like that soap to gel, we recommend soaping at hotter temperatures (120-130F). You can also cover the soap with a towel, and pop it on a heating pad. Read more about gel phase here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/gel-phase/

And more about Auntie Clara’s experiment here: http://auntieclaras.com/2015/09/the-ghost-swirl/

If you want to keep your soap nice and cool, you can pop it into the fridge or freezer for 5-24 hours. That helps prevent gel phase in water discounted and non water discounted soaps. 🙂

Read more about when to insulate soap here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/when-to-insulate-handmade-soap/

As for the essential oil flashpoints, some soapers only like to use high flashpoint oils to prevent scent fading in soap. We have done a lot of testing with essential oils, including low flashpoint oils in hot process soap, and haven’t noticed scent fading. Read more about preventing scent fading here: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/how-to-prevent-scent-fading-in-soap/

If you want to be on the extra safe side, you can pop your soap in the freezer, or use a high flashpoint essential oil. 🙂

Essential oils: https://www.brambleberry.com/All-Oils-C23.aspx

-Kelsey with Bramble Berry

Thank you Thank you Thank you for this post!

I had heard of the term, figured out what it meant- had zero clue how to safely water discount so I’ve never tried it. This post is now bookmarked and will be ingrained into my noggin to use on all my future batches. I live in Arkansas and it’s very humid here even in winter (40%-80% on the norm) and I feel it’s affecting my cure times. At 6 weeks they still seem a little soft on the inside. Almost tacky. I use BBQuick Mixes and calc, and superfat at max (7%) because of my moisturizing needs. Still, I feel my bars need some tweaking. Water discounting sounds like something to try. I’ve been soaping since Sept and just did my first swirl two days ago!

Thank you again for the information that I wanted, but my Google-fu kept veiled.

Hi Allyson!

You’re very welcome, so glad you find the post helpful! I think water discounting will really help with that Arkansas humidity. Let us know how it goes! Also, congrats on your first swirl. It’s so fun to cut into your first swirly batch and see what you created. 🙂

-Kelsey with Bramble berry

Very interesting topic. Thank you I shall give this a try!

You’re welcome Pam! Let us know how it goes. 🙂

-Kelsey with Bramble Berry

I tend to discount just a bit almost every time. Not a specific percentage, but just by rounding the number down. For example, if a recipe calls for 10.8 oz, I’d do 10 oz.. Or on bigger batches, if it calls for say 17.5, I’d do 16 or 16.5 oz.

I have a suggestion not related to this topic. 🙂

I would love it if you could add additional information on your fragrance labels. What I mean is this: on the bottom (in small print) there could be a flashpoint, and if it discolors, accelerates or rices. And maximum usage in soap.

This is how I have to add all that info on my bottles (just an example):

V- 8% D- yes, dark brown A- mild R- no F- 165* 5%

So, it means there’s 8% vanilla in it and it discolors to dark brown. It has mild acceleration and no ricing. Flashpoint is 165 degrees. Max usage 5%, so 0.8/lb. Most are at 5%, but some can be at 1, 2, 3, or 4 % too.

It would save me looking things up all the time. 🙂

And I try to do that on my FOs, but I am way behind, and I have to find the info first. I think that can be a pretty small addition on the bottom of the labels. What do you think? 🙂

I love your suggestion and agree! I keep a spreadsheet with information about each of my fragrance oils and it can be tough keeping it current. Bottle labels would be awesome, and complete information isn’t always available on the web either.

Great news, we are working on labels that will have vanilla content, performance in cold process soap and flashpoint information. We have had a team of people working on it for the past couple months and hope to get started on those new labels soon. 🙂

-Kelsey with Bramble Berry

I am one of those soapers that discounts every time. Amanda, whom you mention, convinced me to try it out and a few batches was all it took to be sold. I’ve got it down so that I can work the batter the way I want as regards swirls and fragrances, and it really does reduce glycerin rivers and ash!

I have just recently starting doing it and I totally notice a difference! It must be working well for you because your bars look just gorgeous. Also, love no soda ash and glycerin rivers! 🙂

-Kelsey with Bramble Berry

This is great! I’ve never really understood the term “discounting” except I assumed it had to do with using less and that there was some specific formula behind doing it. But, wouldn’t water discount, at least extreme ones, make the soap lye heavy?

It would if you discounted so heavily that the lye was not able to dissolve completely. Then you could end up with pockets of undissolved lye in the finished soap!! Yikes!

Hi Michael!

Margaret is right – a lye solution that has too little water can leave the soap lye heavy. It’s important to have enough distilled water so the lye can fully dissolve. We usually like discounting right around 10-15%. That way you get all the benefits of water discounting and the soap won’t be lye heavy. 🙂

-Kelsey with Bramble Berry