You poured your soap into the mold and everything looks wonderful. But, when you look at the soap the next day…ack! There’s a huge crack down the center. What happened? There are several reasons why your batch may have cracked. Below are some of the most common cracking culprits, and how to avoid them.

Too Much Hard Oils, Butters, Wax

One reason why a batch of soap might crack is because of the recipe. Soap is more likely to crack if it contains a large amount of solid oils, butters or wax. The potential for cracking is greater with more brittle butters and waxes, such as cocoa butter and beeswax. In general, I recommend limiting the amount of butters to 15% of your total oils, and the amount of beeswax to 8% or less of the total oils. This post has more information about various butters and how to use them in your soap and other beauty products.

Lots of firm butters like cocoa butter can cause soap to crack. I recommend using no more than 15% butter in your recipe to prevent this.

Lots of firm butters like cocoa butter can cause soap to crack. I recommend using no more than 15% butter in your recipe to prevent this.

Lye Heaviness

To make cold process soap, lye and oils are combined to begin the saponification process. In a balanced bar, there is no lye leftover in the final product – it all gets transformed into soap! If too much lye is added, this can lead to a “lye heavy” bar. Lye heavy batches of soap tend to be dry and can crack. Think your soap might be lye heavy? Click here for information on how to test the pH and how to use it to make laundry soap.

Lye heavy soap can be brittle and may crack. Learn how to test the pH of your soap here.

Lye heavy soap can be brittle and may crack. Learn how to test the pH of your soap here.

Temperature

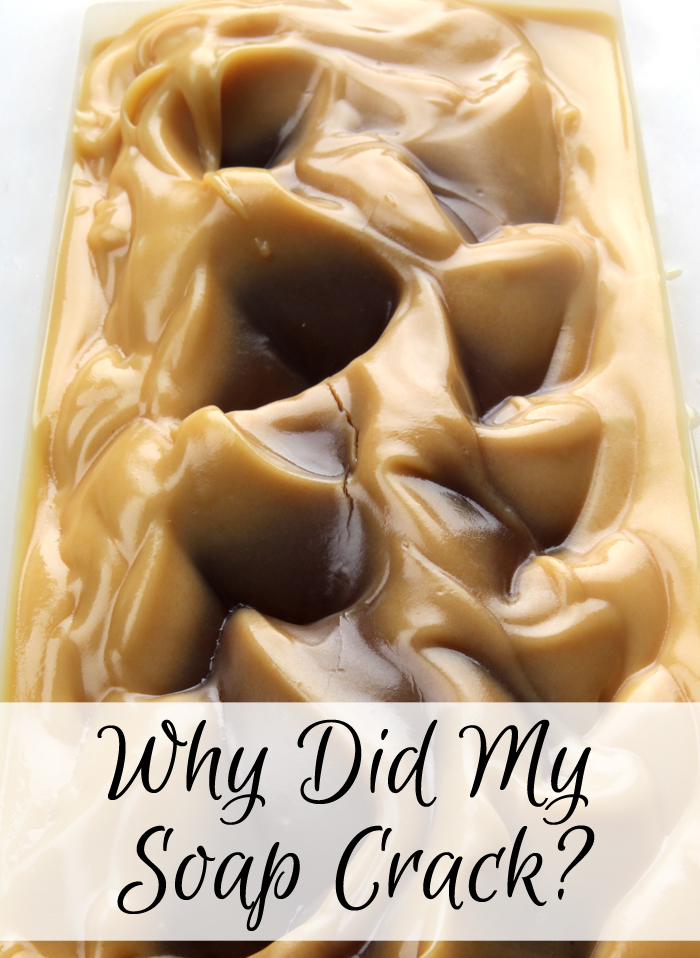

If soap gets too hot, it may crack. The average soaping temperature is around 110-130° F. Once the soap is poured into the mold, it may go through gel phase. ‘Gelling’ and ‘gel phasing’ in cold process soap refers to a part of the saponification (soapmaking) process where the soap gets warm and gelatinous in the mold. During gel phase, the soap can reach temperatures up to 180° F. Click here to learn more about gel phase.

The soap becomes hottest in the center and tends to cool down toward the outside. As the heat makes its way out of the soap, it causes the soap to expand slightly. This can cause a crack on the outside. Temperature is perhaps the most common reason why a soap cracks. It’s even more likely to happen if the soap contains a high percentage of butters, waxes or dry ingredients.

Adding honey to cold process soap can cause an extreme gel phase, which can lead to the soap cracking.

Adding honey to cold process soap can cause an extreme gel phase, which can lead to the soap cracking.

Adding ingredients to soap that contain sugar, such as purees, honey or milk, promote gel phase. In the photo above, honey was added to the soap at trace. The honey caused the soap to go through gel phase and crack in the center. Learn more about adding honey to your cold process soap here. If you add ingredients with extra sugar such as honey, place the soap in the fridge or freezer directly after pouring for 5-24 hours to help prevent gel phase and cracking.

Dry Ingredients

Soap can also crack if it contains ingredients that absorb moisture, such as clay. To compensate for the moisture clays absorb, I recommend dispersing them in distilled water. I usually use a dispersion rate of 1 tsp. clay to 1 Tbs. distilled water. While clays are the most common culprit for cracking, adding too much of any dry ingredients can contribute to cracks. For example, if you were to add lots of colloidal oatmeal, activated charcoal or arrowroot powder without additional water or oil, it may cause the soap to become dry and brittle.

To prevent clays from drying out your soap, disperse them in distilled water. Above, dispersed French green clay is added to soap batter in the Avocado + Spearmint Cold Process Tutorial.

To prevent clays from drying out your soap, disperse them in distilled water. Above, dispersed French green clay is added to soap batter in the Avocado + Spearmint Cold Process Tutorial.

If you experienced a crack in your soap, don’t get discouraged! While it’s not ideal from an aesthetic standpoint, the soap is still safe to use. Just check the pH of the soap to make sure it’s not lye heavy. About 9 times out of 10, a crack is due to heat. Next time, soap a little cooler or place your soap in the fridge or freezer. In my experience, I’ve found cracks are rarely noticeable once the bars are cut! =)

I just made a batch of soap with honey and oatmeal in it. I noticed early on that I had some dark brown seepage on the top. Now that I am almost 24 hour out and have cut it, I still have some seepage. I’m assuming it is harmless but annoying. I’m hoping it will soon dry. Any ideas? I’m assuming I didn’t get the honey mixed well enough.

How did you store your soap once it was in the mold? I’m asking because I think it may be temperature related. If the soap gets hot it can get the liquid on the top like you’re describing. If that’s the case, it will go away in a few days.

Also, to be extra careful you’ll want to pH test it to make sure it’s not lye heavy: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/troubleshooting-lye-heavy-soap/

Hi! I just completed my second batch of cold process soap ever yesterday. Today it has a huge, deep crack through the top. From this article, I can guess why. I used two recipes, one for the base soap and another for the soap frosting on top. The soap frosting recipe contains mostly hard oils. However, it was my understanding that this is necessary for soap frosting to make firm peaks. I worked at room temperature and did not insulate the soap.

Is there something I can do to help prevent cracks in this case?

One more question: do you think it would be possible to use melt and pour to help fill and camouflage the crack?

That is correct, the hard oils in the soap frosting help it hold its shape. I’m not sure why your recipe cracked. What oils did you use? Also, did the soap get warm at all at room temperature?

As for the cracks now, you can definitely try using melt and pour. We haven’t tried that so I’m not sure if it will work. You may also try making a small batch of cold process soap to help disguise the cracks.

I used equal amounts of palm oil and coconut oil, and a smaller amount of olive oil. It did heat up quite a bit after it was in the mold, most likely due to the fragrance oil, which was a pumpkin spice. I’ve read spicy and floral fragrances can have that effect.

Could leaving the fragrance oil out of the frosting next time help?

I think instead of leaving the fragrance out, try popping the soap in the fridge for 5-24 hours when you’re finished. That will help keep it cool and prevent that cracking. It also helps the frosting hold its shape.

I’ll definitely try that next time. Thank you so much for your time and advice!

You’re welcome, let me know how the next batch goes. 🙂

Can soap crack because its too cold? Lately I’ve been making soap with cooled lye/oils at around 68F. The oils are cloudy, but I’ve found that the oil and lye still combines just fine.

sorry forgot to say that my last batch with this method developed a few tiny cracks on top.

I’m using a 33% lye concentration and added sodium lactate and did a light spray of 70% isopropyl alcohol. No beeswax, milk or sugars, but I do have 37% lard and 20% coconut oil in my recipe. I use a wood mold but do not use a lid or other insulation. I read on another comment you say that soaping cold does not cause cracks. I used this exact recipe twice before this week with no cracking, and the only difference is that I forgot to add sodium lactate and also the fragrances/colors were different. I need to add sodium lactate though because otherwise the soap is quite sticky after 24 hrs. Is there anything I can do to prevent this cracking? If i added an lid would that make a difference? On another note, I used to soap at 110 degrees and the mold would feel hot to the touch during saponification. It doesn’t feel hot anymore now that I’m working at 68 degrees. Does that mean gel phase is not happening? Because these are new colors/fragrances I’ve not used before I can’t really tell if its gelled or not.

Does the soap have an ashy appearance and a slightly powdery feeling? It may be soda ash that’s causing the cracking.

How are you storing your soap? If the temperatures are lower and it’s not insulated, it’s likely not going through gel phase.

yes there is a little ash on top but not much. Is there a way to prevent it?

I’m storing it in the same room as I make it, at 68 degrees. It is insulated by the wood mold, so I thought there would at least be some partial gel but i see no evidence of that. I used to always put a lid and towel on top but then I got a cracked soap one day (after soaping at 110F) when using a vanilla fragrance oil, so I stopped doing it. But it seems I have cracking whatever I do!

sorry i mean is there a way to prevent the cracks due to the ash.

If it’s cracking at both cool and warm temperatures, I’m wondering if it may be the recipe. What other oils are you using besides the lard and coconut oil?

Hi. My soap turned out fine in the first batch, though It crumbled while using. However, in my second batch, I tried doing hardness test and dropped the soap on a cemented floor and it breaks whereas another commercial soap didn’t, please what do I do?

What oils are you using in your recipe? You can add more hard oils like coconut and palm to make the soap harder. Also, what superfat are you using?

So, please excuse my ignorance but I thought the gel phase was something we wanted but is it better not? My last batch of soap got a large crack down the middle but the only thing I can think (after reading all this) is that I shouldn’t have insulated it at all. Should I xput it right in the freezer after pouring in the mold? Thanks Yadel

Gel phase is optional and doesn’t affect the quality of the soap at all. Some soapers choose to gel their soap because it makes the colors pop. However, if the soap gets too hot it can crack. Also, if there are ingredients like milk, gelling can cause scorching. Whether or not you insulate the soap depends on personal preference, your recipe, the temperatures in your home, etc. This post talks more about when to gel: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/when-to-insulate-handmade-soap/

And this one talks more about gel phase: http://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/gel-phase/

If your soap cracked, you can leave it at room temperature with no blanket or heating pad, or you can pop it in the fridge or freezer for 5-24 hours. That will help prevent that cracking.

-Kelsey with Bramble Berry

I’ve just recently started making soaps, and I’m about 4 batches in when this last one I did cracked on me. Total Bummer!!! But, my question is on the coconut oil should you strictly use “unrefined” or “refined”? In all of my other batches I used “unrefined” this one I just made that cracked I used “refined.” (Which it totally my fault for not paying attention)

Usually, cracking is due to the factors mentioned above and not whether the oil is refined. How much coconut oil did you use in your batch? What temperatures were your lye and oils and how did you store it?

-Kelsey with Bramble Berry

28oz Coconut Oil

5oz Lye

12.5oz Distilled Water

The temperature was around 110 F. I poured the soap in a rectangle silicone mold that sits in a wood box and I put it in my pantry.

I have used this recipe before and it turned out just fine.

A couple of ideas to try are to lower your temperatures – it could be cracking from the heat. Anther thing to try is to increase your superfat %. In our test with pure coconut oil soap we had issues that were solved when we used a superfat of 10%. Hope one these ideas helps!

Hi Kelsey, I made my first batch of cp soap. I measured everything to the exact ounces, melted the oils and let lye water sit and cool. The oils and lye water were both combined at 100* degrees, they blended great and I used a stick blender to get a medium trace. Added fragrance and colour and poured into mold. All was a beautiful shade of pink, waited a 36 hours to unmold……. the problem, the soap was soft, it came out, but smelled like play dough ??? Over the next couple of days it changed colour to a tan around the edges ??? All the smell of the fragrance was gone…. What did I do wrong. This is what I used, the recipe was from a soap class I had taken in the spring, a practice recipe. 3.3oz olive oil. 3.3oz canola oil. 2.2oz coconut oil. 2.2oz lard. 4 oz distilled water and 1.49oz lye Thanks Therese

What fragrance did you add? I’m thinking the fragrance may be discoloring. Also, how old are your oils? Does it still smell like Playdough?

-Kelsey with Bramble Berry

My oils are newly bought within 3 months, and yes it smells like play dough….. I put in summer berries FO from a local Canadian company, I only used 1/2 ounce. Since I’m new to soaping I need all the help I can get. Thanks Therese

Does that fragrance have any vanilla in it? Did those oils come from a grocery store? Also, what kind of water did you use? Thanks for answering my questions Therese.

-Kelsey with Bramble Berry

Hi today I made a 88% coconut oil soap with 6% kokum butter 1% Beeswax and 5% castor oil with 20 percent superfat. I have gone with water discount 2.5:1(lye) and substituted most of the water with coconut milk. The soap traced pretty quick. I soaped at around 127 degrees.Even in the freezer my soap turned darker and it had a crack down the middle. After reading your article I could guess what could have gone wrong. Is it mainly due to the addition of only hard oils and butters in the recipe? Your advise will help me a lot.

Soap made with 88% coconut oil and beeswax will trace pretty fast. Water discounts can also make it trace quickly. That is normal for soap made with mostly hard oil. Also, coconut oil has natural sugar, which can cause the soap to overheat, especially if you’re working with beeswax, which needs to stay warm. For your next batch, it can help to do a smaller water discount, or skip it entirely. The soap will be hard in just a few hours because of the hard oils.

Then, you may want to skip the beeswax or the milk. If you skip the beeswax, you can soap at lower temperatures to keep the milk cool. If you skip the milk, you can soap at warmer temperatures to keep the beeswax melted. 🙂

-Kelsey with Bramble Berry

Hey Kelsey. Thanks for the reply. Yesterday I tried the same recipe sans beeswax and the temperature was between 110 and 120 degrees with no water discount. Sadly it cracked again formed partial gel ring in the center with droplets of oil oozing out (I think its my E.O. blend of lavender, rosemary and cedarwood) 🙁 . Should I give the milk part a miss altogether from these kind of recipes ?

Did you put the soap in the freezer afterward?

-Kelsey with Bramble Berry

Yeah.. Everything same as before except the beeswax

I’m thinking more soft oils and a smaller water discount will help! A high amount of coconut oil hardens really quickly even using the full amount of water. You can also replace some of that coconut oil with a soft oil like olive, sweet almond, or avocado. That should make the bars softer and prevent that cracking. 🙂

Just remember to run your recipe through the Lye Calculator after any substitutions: https://www.brambleberry.com/Pages/Lye-Calculator.aspx

-Kelsey with Bramble Berry

Olive oil: https://www.brambleberry.com/Olive-Oil-Pure-P5246.aspx

Sweet almond oil: https://www.brambleberry.com/Sweet-Almond-Oil-P3205.aspx

Avocado oil: https://www.brambleberry.com/Avocado-Oil-P3198.aspx

I just made my first 100% coconut oil soap using 20% superfat. I took 4 oz of water out of the recipe and added coconut milk in its place. Within 45 minutes of it being in the mold it is almost completely gelled and the top cracked a little bit. It started getting hot as soon as I added the coconut milk and it was thickening so fast I had to plop it in the mold by the end. Any suggestions so this doesn’t happen next time? Should I keep the coconut milk out of it?

Coconut oil thickens really quickly, so it will move pretty fast! The natural sugar in coconut milk will heat the soap as well. It helps to soap at lower temperatures (around 100F). Then, once the soap is in the mold, pop it in the freezer for a couple hours to keep it cool. Then, remove to room temperature and cut when the soap is firm to the touch. That happens pretty quickly! 🙂

Learn more about coconut oil soap here: https://www.soapqueen.com/bath-and-body-tutorials/100-coconut-oil-annatto-soap-tutorial/

-Kelsey with Bramble Berry

Dear i need ur help

i have my own manufacturing soap plant.Recently i introduced my new soap in market but the thing that making me hopeless is that after washing hands my soap convert into cracks lots of cracks.tell me the right method of making soap.i used soap noodels, lye ,glycrien ,sodium laurethsulfate (shampo base), water.i made my soap by hot process method.im so disappointed plz help me.

I think it may be the lye. Soap noodles are a finished product, so the added lye may not be turning into soap. Instead, it may be activated and cracking the soap and may hurt your skin. You will want to check with the manufacturer to be sure.

-Kelsey with Bramble Berry

Thnx Dear.And other thing i want to ask my dear is that can u tell me the oils quantity and lye quantity and temp of cold process soap which u make.I try a little bit but my soap trace is so hard so that i can not add colors and other things.

2.25 ounce lye

6.10 ounces of water

mix it and cold it for 100 degree

shea butter 3.2 ounces

coconut oil 4 ounces

palm oil 4 ounces

melt it for 100 degree

and olive oil 4.8 ounces

BUt the soap trace become harder not in liquid form tell me the right way..and again thanx 4 reply me.

Absolutely! When I ran your recipe through our Lye Calculator I got 2.24 oz. of lye and 5.28 oz. of water, so your amounts look good. I’m thinking it’s the oils in the recipe. When you have hard oils like coconut, palm and shea, they will trace faster than liquid oils like olive oil. You can increase the olive oil and decrease the shea/palm. That will make your soap trace more slowly. It also helps to up your temperatures to around 110-115F. That will ensure all the hard oils stay melted and don’t solidify when you’re making soap. 🙂

Learn more about slow-moving oils here: https://www.soapqueen.com/bath-and-body-tutorials/tips-and-tricks/five-tips-swirling-cold-process-soap/

-Kelsey with Bramble Berry

Oky i will do it by ur method and thanx again kelsey.thanx alot for helping me

I have been making the same soap recipe for a couple weeks and this is the first time that i’ve found a big crack…. I am making Balsam fir soap nice scent with titanium dioxide swirl. I’m not sure if its the Balsam fir essential oil….. please help… Also i mixed my oils and lye water at 85 degrees.

Hi Leigh! How did you store your soap? If you’re using lower temperatures but forcing gel phase, it can still crack. Also, how much butter is in your recipe (if any)? Do you have any clay in the recipe? Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry

Will covering with plastic slow down the rate of evaporation?

That can help slow evaporation, but it can also heat the soap up even more, which can cause the cracking as well. Mixing your oatmeal with oil can definitely help! Using less butter and more soft oil in your soap helps as well. You can also cover the soap with a towel or plastic wrap, but make sure it watch it closely. If you find it getting too hot, you can take the insulation off. 🙂

-Kelsey with Bramble Berry

My soap began cracking shortly after pouring. I used colloidal oatmeal AND calendula. It makes sense to saturate dry ingredients prior to adding. Live and learn. Hope to salvage these very expensive aloe loaves.

Mixing the oatmeal with oil can definitely help prevent cracking! The good news is the soap is still fine to use. If the cracks aren’t very deep, you can use something like our Soap Shaver to smooth out the top: https://www.brambleberry.com/Soap-Shaver-P6331.aspx

If they’re fairly deep, you can rebatch the soap! That can help smooth it out nicely. 🙂

Learn more about rebatching soap here: http://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/soap-queen-tv-presents-how-to-make-rebatch-soap-2/

-Kelsey with Bramble Berry

Hello,

I made the clover and aloe spin swirl using oxides and micas, and it had split the following morning. Does mica cause this? The split in the soap is where the black oxide meets the bronze mica, but interestingly it’s also split perfectly around a black section too following the swirl perfectly, but maybe there is bronze mica under that black swirl. Is this a possible cause? I followed your recipe but substituted palm oil and caster oil for for 3oz mango butter, 3.3oz cocoa butter and 2.5oz hempseed oil. Wondered if the mica could cause layers to separate and split because I kept butters to a minimum.

wanted to add I poured lye and oils at 110oF and didn’t cover the soap, I don’t think it’s high temperatures either :/

Hi Sienna! Just to clarify, did your soap crack on top? That can be heat-related, but it can also be caused by butters or too much sodium lactate. Did you add any sodium lactate? If so, how much? Also, how hot is your house? Let me know and we’ll figure this out. 🙂

-Kelsey with Bramble Berry

Hello! I don;t think heat because our house was really cold (ran out of chopped wood 🙂 ) so around 50-55oF and I mixed the oils and lye at around 110oF. It is cracked on top yes, following the swirl perfectly. The largest is between the black oxide and bronze mica and a smaller long crack goes along and around a thin black swirl. I kept butters to a minimum as I know cocoa etc can cause cracking, unless you think the 6.3oz is still risky? As for sodium lactate, maybe I should keep that out too, I measured out about two teaspoons, but I maybe three went in as I grabbed my dodgy measuring spoon! Hoping it’s that simple as the effect is beautiful. I’m trying again without micas in case that’s the issue, but suspicious as one crack is directly running through the black oxide.

Also if it helps with diagnostics, the black iron oxide part that cracked is “puffy”, I gently pressed down to try and seal the crack and some of it came away onto my glove from the soap surface like marshmallow fluff, the whole area looks slightly raised compared to the other three colours.

Do you have a picture of the soap? That would be super helpful! You can send that to me on our Facebook page: https://www.facebook.com/BrambleBerry/

-Kelsey with Bramble Berry

I am wondering if you have ever had soap that was poured in layers crack apart? I made a patchouli soap last week, and added coconut milk to half the batch to create a two-tone effect. While the color is better than I had hoped, the two layers are cracking apart. Is there anything I can do to fix it? Almost every bar is separating where the two colors meet.

Hmm, I’m not sure why that is happening! Can you tell me a bit more about your recipe? Also, did you spray any alcohol in between the layers? How long did you wait in between pouring the layers? Let me know and I’ll help you troubleshoot. 🙂

-Kelsey with Bramble Berry

I actually use a palm-free recipe from this site, and I boil down Guinness beer to use in place of water to give it a nice tan color. Normally I put coconut milk in it. This time I divided it in two, and only put the coconut milk in half the batch. I now think it must have decreased the temperature too much. And no, I didn’t spray alcohol between the layers, I just learned that trick the other day. Is there anything I can do to repair my cracking-apart layers without melting it down and starting over? It did come out with two lovely tones, I would hate to lose them.

I had the same thing happen. I made a lemon verbena loaf. I sprayed alcohol between the two layers and popped it in the fridge immediately to keep it from gelling. The bottom layer was fine, but the top layer became flaky and separated completely from the bottom layer when I cut the bars. I’m not certain what happened, but I’ve noticed this a couple times now when there is a high amount of hard oils in the recipe or when I refrigerate the loaf. For this particular one, I used illipe butter, mango butter and cocoa butter along with coconut oil, safflower and Sweet Almond oils.

Hi Jennifer!

We usually don’t recommend spraying alcohol in between cold process soap. You can spritz a tiny bit to help distribute a mica line, but too much can make the layers separate. I’m sorry about any confusion. I went ahead and updated the Lemon Poppy Seed Cold Process Tutorial with instructions to lightly blow on the soap, rather than using alcohol. That helps prevent that separation! Were you using mica lines in either of the recipes? Also, how much butter did you use in your recipe? Did you have more liquid in one layer? Thanks for answering my questions!

-Kelsey with Bramble Berry

Lemon Poppy Seed Cold Process Tutorial: https://www.soapqueen.com/bath-and-body-tutorials/cold-process-soap/lemon-poppy-seed-cold-process/

Nice article! My soap usually breaks while taking shower. Lowering tthe use of essential oils at the top and avoiding overheating can helps in making soap hard and can’t break. BTW thanx for sharing!

You’re welcome Rebecca, glad you liked the post! 🙂

-Kelsey with Bramble Berry

Great article as always. I only had one loaf to crack and it also developed what you folks refer to as alien brain. I knew as soon as I uncovered what happened. I added honey to it at trace for the color and I soaped it hot and I insulated it very well so I knew immediately that it got too hot. Fortunately, the crack was in the middle only and was not deep so I was able to trim the alien brain off the top of the cut bars and I used the cracked portion for myself. Lesson learned! I wish I had known about this site then!

That’s awesome, I’m glad you were able to trim off the alien brain so the soap looks nice and smooth. I love that about soap – even if it’s got some bumps or cracks, you can shave those off. Not to mention the soap still feels awesome on the skin. 🙂

-Kelsey with Bramble Berry

I had a batch of soap crack recently. It was a mostly soft oils recipe that I had used before with great results. This batch the only thing I did differently is after 2 days making it, I put it in the freezer so I could unmold (I was impatient and it wasn’t quite ready to come out on it’s own…). I unmolded, no cracks, everything looked great, but by the next day there were huge cracks along the bottom.

I think it was from the still-pretty-soft soap warming up after being frozen, but maybe I’m off base? Let me know what you think and thanks for the excellent post!

Hi Allison!

To be honest, I’m not quite sure why that happened! Typically soap cracks for the reasons listed above, but your recipe was softer and didn’t get too hot. What kind of mold were you using? Also, do you have a picture of the soap? That would be really helpful! You can post that on our Facebook page and I can take a look there. 🙂

Bramble Berry Facebook page: https://www.facebook.com/BrambleBerry/

-Kelsey with Bramble Berry