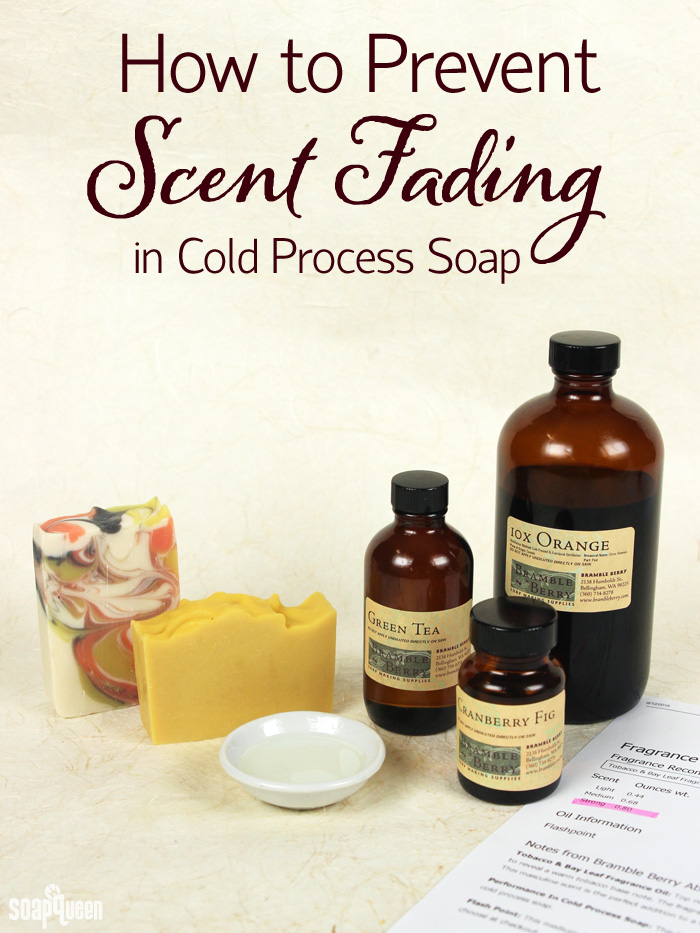

The first time you smell a fragrance or essential oil out of the bottle is definitely memorable. A fragrance can immediately inspire designs, colors and additives for your next soap recipe. But, sometimes the fragrance and essential oils can fade or change in cold process soap. The pH level of cold process soap can attack components of the oil, causing them to smell differently. It can be very disheartening! All Bramble Berry fragrance and essential oils are tested to ensure the scent sticks to cold process soap for months after making the soap. That being said, there are tips and tricks to make scents last even longer.

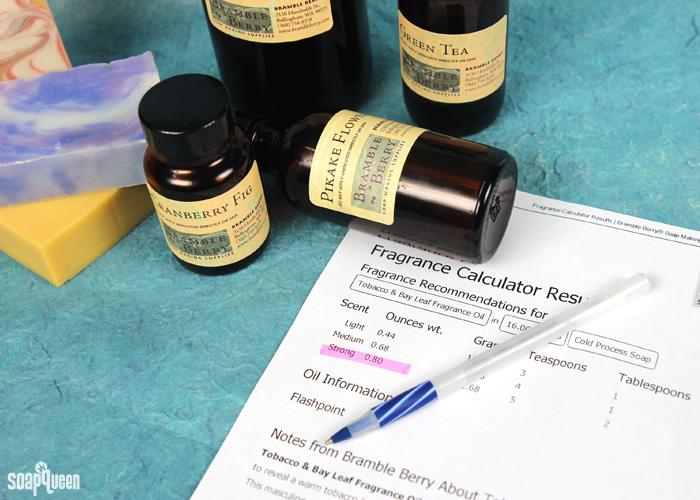

How much fragrance or essential oil used in the recipe plays a big role in scent retention. For a strong scent, with regulations taken into account, you can add .8 ounces of fragrance or essential oil per pound of cold process soap. For melt and pour, you can add .25 ounces of essential oil per pound, or .5 ounces of fragrance oil. This number will vary based on the scent selection. For instance, Almond Fragrance Oil is on the stronger side. Just .16 ounces per pound of cold process soap will provide a hefty scent. To find out exactly how much to add to the recipe, check out Bramble Berry’s Fragrance Calculator. Find out how to use the calculator here.

The Bramble Berry Fragrance Calculator amounts are based on safety guidelines created by IFRA (International Fragrance Association) and RIFM (Research Institute for Fragrance Materials). Each fragrance and essential oil have a maximum usage rate that is deemed safe for bath and beauty products. The “strong,” amount of fragrance recommended by the calculator is based on this maximum usage rate recommended by IFRA and RIFM. Using more than this amount can cause skin irritation.

Even with the highest scent recommendation, some scents don’t make it through cold process soap making. Cold process is a harsh environment, as it goes through several pH changes. Coconut scents, like Coconut Cybilla Fragrance Oil, can be very light in cold process soap. This is also the case for citrus essential oils, like Lemon Essential Oil and Orange Valencia Essential Oil. Still want a coconut or orange scent that lasts? You can use Coconut Cream Fragrance Oil or 10X Orange Fragrance Oil. Check out the tutorials using those fragrances below.

Left to right: Juicy Orange and Sweet Rose Cold Process Soap, Coconut Cream Pie Cold Process Soap

Left to right: Juicy Orange and Sweet Rose Cold Process Soap, Coconut Cream Pie Cold Process Soap

Don’t give up on citrus or coconut scents just yet! They work great in melt and pour soap and other bath products, like the Coconut Oil and Pink Salt Scrub. That tutorial uses Island Coconut Fragrance Oil and Lime Fragrance Oil. You can also anchor light scents. That involves pairing them with a deeper, earthier or more complex scent to “anchor” the fragrance in soap. Some examples of anchoring scents include Amber Fragrance Oil, Patchouli Essential Oil and Sensuous Sandalwood Fragrance Oil. In the Lime in the Coconut Milk Cold Process Soap, Lime Distilled Essential Oil was paired with earthy Coconut Lemongrass Fragrance Oil to help it stick.

This Lime in the Coconut Milk Cold Process Soap uses earthy lemongrass to anchor the lime scent.

This Lime in the Coconut Milk Cold Process Soap uses earthy lemongrass to anchor the lime scent.

Some soapers like to use kaolin clay in their soap to help hold scent. While we haven’t done a lot of scent testing with kaolin clay, we have found it adds a nice “slip” and subtle color to soap. Kaolin clay was used in the Sea Clay Swirl Cold Process Soap. To add it to your soap, mix 1 tsp. of clay in 1 Tbsp. of distilled water beforehand. That helps it disperse evenly. It also prevents clumping and acceleration, as clays tend to absorb moisture. Read more in the Sunday Night Spotlight: Brazilian Clay.

Kaolin clay gives the Sea Clay Swirl Cold Process Soap a subtle white color.

Kaolin clay gives the Sea Clay Swirl Cold Process Soap a subtle white color.

Temperature is another factor to consider when soaping. Each fragrance and essential oil has a flash point, which is the temperature at which, under certain circumstances, the liquid in question can ignite with a flame. This means the liquid needs to be at the flash point temperature and come in contact with an open flame. Some people believe if a scent is heated to the flash point temperature in recipes, it can cause the fragrance to fade.

We haven’t noticed substantial scent fading at higher temperatures, but it is something to take into consideration. If you’re using a low flash point scent, you may want to avoid gelling the soap. During gel phase, soap can get as hot as 180 ° F. Read more about gel phase here. It may be something to consider when making hot process soap as well, as the soap temperatures are typically around 160 ° F or hotter.

Some soapers only use medium or high flash point oils when making hot process soap, like the Marbled Clay Hot Process Soap.

Some soapers only use medium or high flash point oils when making hot process soap, like the Marbled Clay Hot Process Soap.

To ensure the scent stays strong during the cure, store it in a cool, dry place that’s not in direct sunlight. Learn more about storing your products here. You can also dip a cotton ball or balled up paper towel in the fragrance or essential oil and place it by the soap while it’s curing. That is thought to help the soap “absorb” some of the scent as it cures. Just remember that fragrance oils and plastic do not get along, so be sure your cotton ball is not sitting on a plastic surface. Click here to read more about how plastic and undiluted fragrance oils don’t mix.

Storing your soap in a cool, dry place out of direct sunlight can help that scent stick.

Storing your soap in a cool, dry place out of direct sunlight can help that scent stick.

For the best scent retention, make sure the fragrance or essential oil you’re using has been tested thoroughly and is approved for use in soap. We test all of our scents and include performance notes in the essential oil and fragrance oil descriptions.

Do you have any tricks for making scent last? Personally, I like to scent my soap recipes on the stronger side to ensure my fragrance really comes through.