Rebatching Soap – What is it and why would I do it? – Rebatching is another form of cold process soapmaking. You can either make cold process soap from scratch or buy a premade base, grate it up, place it over a heat source, either in a double boiler or in a freezer baggie as shown below, with a little liquid (water, beer, milk, teas all work well). This mixture “melts” down into a mushy mess that you add colorant and fragrance too. The reason people normally rebatch is to preserve the delicate scent or the healing properties of some essential oils.

Rebatching Soap (make it yourself or buy a premade base)

Fragrance or Essential Oil

Mold (the less detail, the better)

Optional: Herbs

Colorant (liquid works best)

Freezer Bags (must must must be heat safe)

Grater

Large Bowl

Spoon

Step One: Grate the soap. I’ve tried a variety of things (food processor, meat grinder, deli meat slicer) and all of the cutters have gummed up on me and not worked after a few ounces worth of soap grinding. If you have any great tips, please post them here and save us some time and arm soreage.

Step Two: Bring a large pot of water to boil. Fill a freezer bag (heat safe) with the grated soap and approximately 1/2 to 1 ounce of liquid. Submerge the freezer bag of soap in the boiling water. Be sure to use a large enough pot that the freezer baggie will not be squished up against the side of the pot. You don’t want to accidentally melt the plastic baggie.

Step Three: Once the soap has boiled in the large pan for approximately 20 minutes, the soap should be gelatinous and gloppy, sort of like mashed potatoes or thick soupy oatmeal. It will never “melt” and become water like.

Step Four: Using heat safe gloves (that soap is hot! wear gloves!), pull the soap out of the water. Knead it around to make sure the liquid is fully mixed into the soapy gloppy glory. Is it too thick? Add another 1 Tablespoon of liquid if needed and knead this into the soap. The key is to not use very much liquid. The more liquid you add to this process, the thinner the soap gets (true) but the longer it will take to dry and harden.

Step Five: The photo above shows the soap midway through the softening process. It’s not perfect yet. Put that soap back into the boiling water.

Step Six: The photo above is perfect texture. It looks like thick Vaseline. It is now ready for the color and fragrance.

Step Seven: Add fragrance and color. Liquid color is ideal (mixing pigments into the gloppy soap is difficult). I use approximately .5 ounces of fragrance or essential oil per pound of soap. The colorant usage varies based on the color but start sparingly. You can always put more color in but taking it out is difficult. If the soap starts to harden up at any point because it is cooling, reseal the bag and toss it all back into the hot water. Make sure you wear heat safe gloves through this entire process. The soap is hot.

Step Eight: You can either spoon the soap into the molds or pour/push/squeeze the soap out of the baggie. Unless you are an experienced rebatch soaper, I would not recommend cutting off a corner of the bag to squeeze the soap out like frosting. It’s tempting but if the soap starts to cool too quickly, the open hole will not allow you to remelt the soap in the boiling water.

Step Nine: Take the mold you are using, close your eyes and give it a good wack on the counter to settle the soap and get all the air bubbles to the surface of the bar. When the soap starts to cool, feel free to use your hands and fingers to smooth out any bumps on the surface.

Wait for 2 to 7 days before popping the soap out. The key is to wait for all the liquid to evaporate. Yes, you can become impatient and freeze the soap but make sure the soap is entirely frozen (overnight at least) before trying to pop the soap out and remember that plastic is more brittle after it is frozen so be gentle on your molds.

Check back in the next few days for a tutorial on how to do rebatching soap via the double boiler method. This is my favorite way to do rebatch and you can do larger batches with the double boiler method.

Using more firm oils and butters in your recipe will result in a firmer bar of soap.

Using more firm oils and butters in your recipe will result in a firmer bar of soap.  Adding too much extra oil (like with dispersed colorants) can lead to a soft bar of soap.

Adding too much extra oil (like with dispersed colorants) can lead to a soft bar of soap.  Water discounting soap reduces the chances of glycerin rivers, shown above. It also produces a bar that hardens faster.

Water discounting soap reduces the chances of glycerin rivers, shown above. It also produces a bar that hardens faster.  The bar on the left contained sodium lactate, while the bar on the right did not.

The bar on the left contained sodium lactate, while the bar on the right did not.

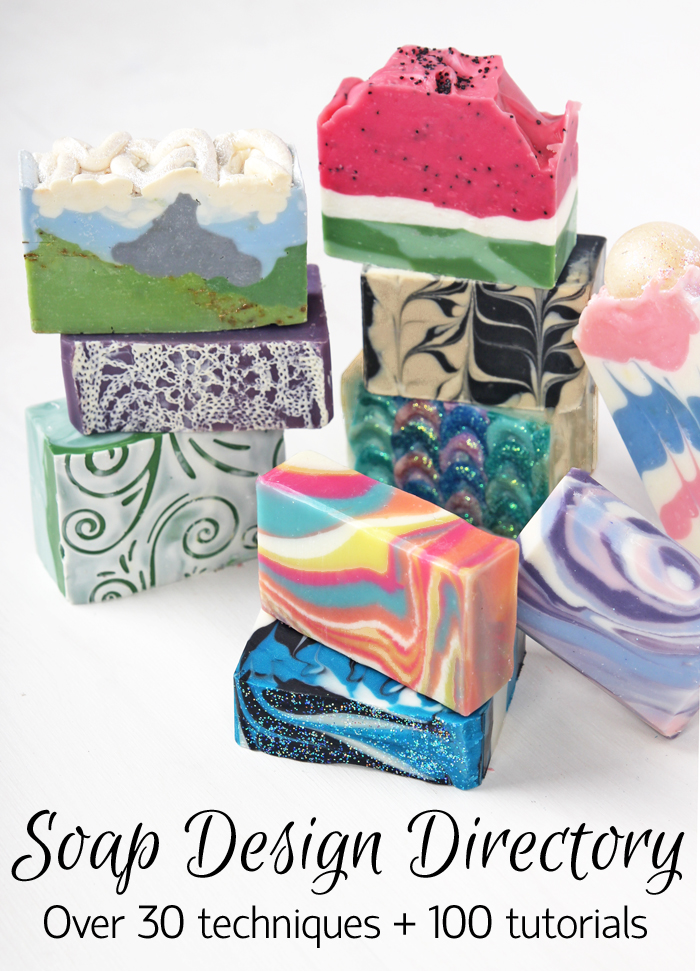

Far left, clockwise:

Far left, clockwise:  If you have a lot of gifts to give,

If you have a lot of gifts to give,  Left to right, clockwise:

Left to right, clockwise:

Top row, left to right:

Top row, left to right: