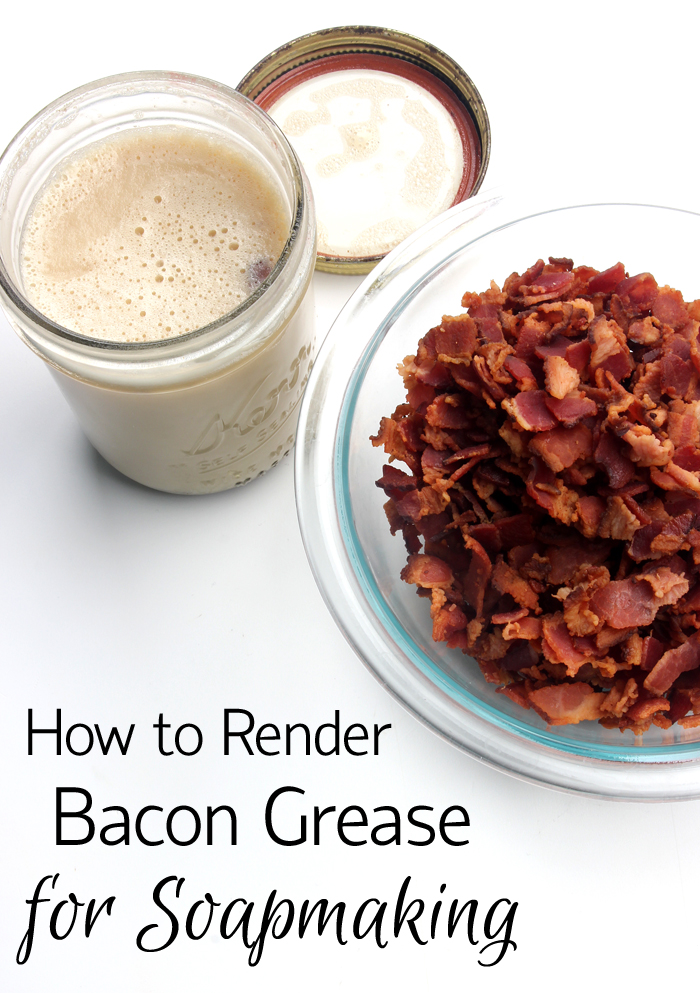

Hypothetically, you can make cold process soap with just about any oil or fat. This includes animal fats. The most common animal fats are lard and tallow. Lard is rendered pig fat, while tallow is rendered fat from meat other than pork such as cow, lamb or goat. Tallow and lard are excellent for soapmaking. Both contribute to the firmness of the bar and a stable lather. Lard and tallow are commonly used as palm oil substitutes. If you’re interested in learning more about the benefits of tallow in soapmaking, check out the Understanding Tallow for Soaping guest post.

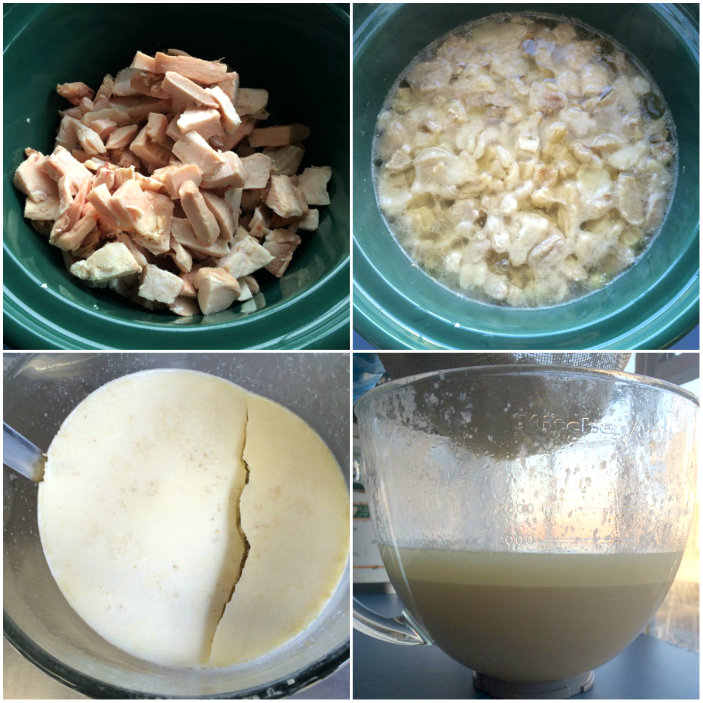

Lard and tallow can be purchased at the store ready to use. Or, you can render your own at home. The basic idea of rendering lard and tallow involves “cooking” the fat along with water. Then, the entire mixture is placed into a container to cool. The fat will rise to the top of the container, while the water will fall to the bottom. This process helps remove any particles within the oil. The process may vary slightly depending on what form the fat is in. For example. if you got your tallow from a butcher, you most likely have chunks of fat and meat that will need to be strained. Our local sister store, Otion, rendered tallow from a local butcher in the Crock-Pot (shown below); click here to see how they did it. They used the rendered tallow to make Mahogany Tallow Soap. This is a topic we’ve touched on before here and here.

Otion Soap Bar recently rendered chunks of tallow in the Crock-Pot for soapmaking, click here to see the process.

Otion Soap Bar recently rendered chunks of tallow in the Crock-Pot for soapmaking, click here to see the process.