The natural sugar in beer boosts lather in cold process soap, and it’s also great from a marketing perspective. This soap is colored with activated charcoal and titanium dioxide to create a dramatic contrasting swirl. Because Oatmeal Stout Fragrance Oil does discolor, it’s added to the charcoal portion only. Over time, the discoloration will migrate slightly into the lighter portion – but will still look great! The lather does have a slight color, due to the charcoal and fragrance.

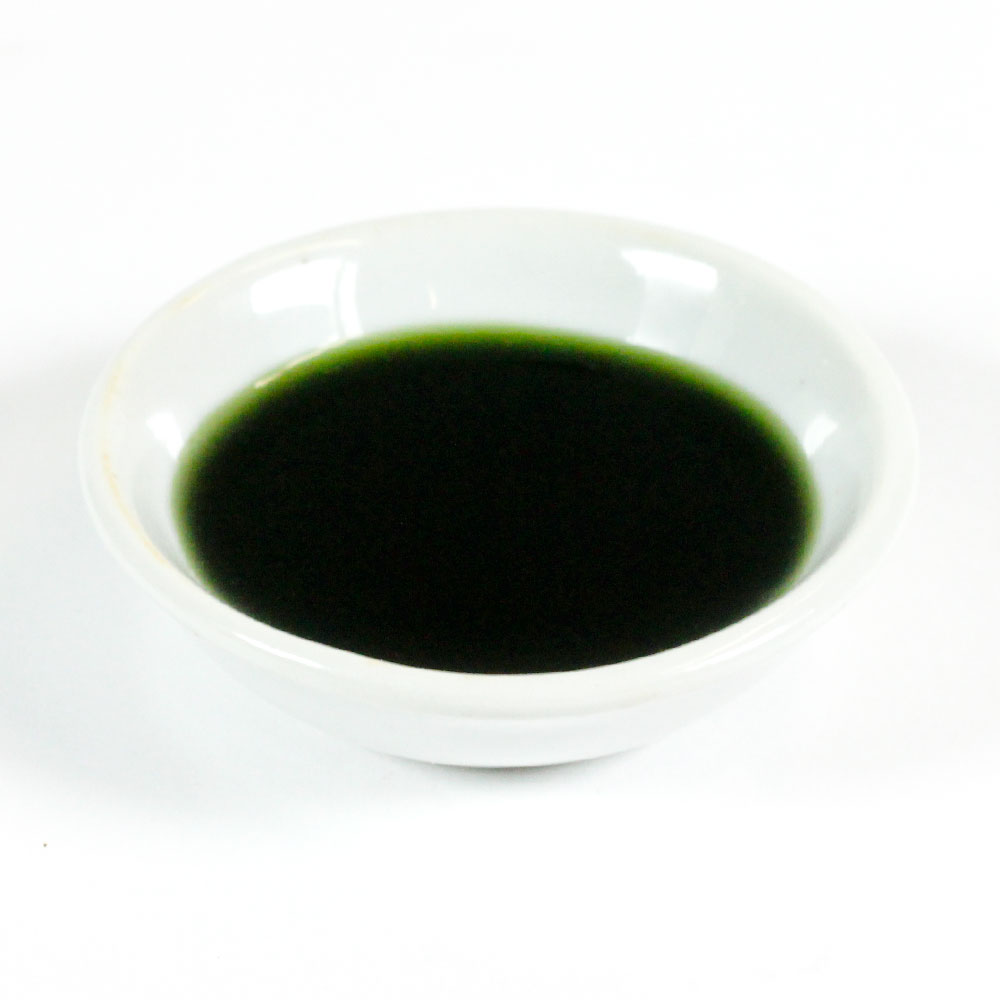

Working with alternative liquids takes a little extra prep work. In this case, that means boiling the beer to remove the alcohol and letting it sit uncovered for 1-2 days to get rid of carbonation. You can also freeze the beer to prevent further discoloration. Because this soap features a darker color palette, we were not concerned and added the lye directly to the boiled and chilled beer. Because of the extra prep work, we recommend this recipe for more advanced soap makers.

Toushonta Hogan, the founder of Scensational Soaps, creating a batch of cold process soap.

Toushonta Hogan, the founder of Scensational Soaps, creating a batch of cold process soap.  Beautiful baskets of Scentsational Soap products.

Beautiful baskets of Scentsational Soap products.

Scentsational Soaps on the shelf at Target.

Scentsational Soaps on the shelf at Target.