When I think of wine production, my mind immediately jumps to beautiful images of Napa Valley in California. But, you may be surprised to know that Washington state is the 2nd largest wine producer in the United States. Most of the wine is produced in Eastern Washington, where temperatures are warmer. To highlight this ingredient in my local area, the water in this recipe is swapped for wine produced in Washington state.

Working with wine in soap is not particularly difficult, but it does require some extra prep work. Alcohol and cold process soap don’t mix very well. So, when incorporating alcoholic beverages into recipes (such as beer, wine, etc.) the liquid needs to be boiled first to remove the majority of the alcohol. Then, I like to freeze the liquid and add the sodium hydroxide lye to the frozen liquid to keep temperatures cool.

Alternative liquids like wine have extra sugar, which scorches when mixed with lye. If the temperature of the liquid is kept cool, less scorching occurs. This keeps the liquid a slightly lighter color and reduces the unpleasant odor. Red wine is already quite dark, so if you’d like to skip freezing the wine you could. Keep in mind your soap batter might be slightly darker (and stinkier!). If you skip the freezing step, I do recommend allowing the wine to 50 ° F or cooler before adding the sodium hydroxide lye. Learn more about working with alcoholic beverages in soap here.

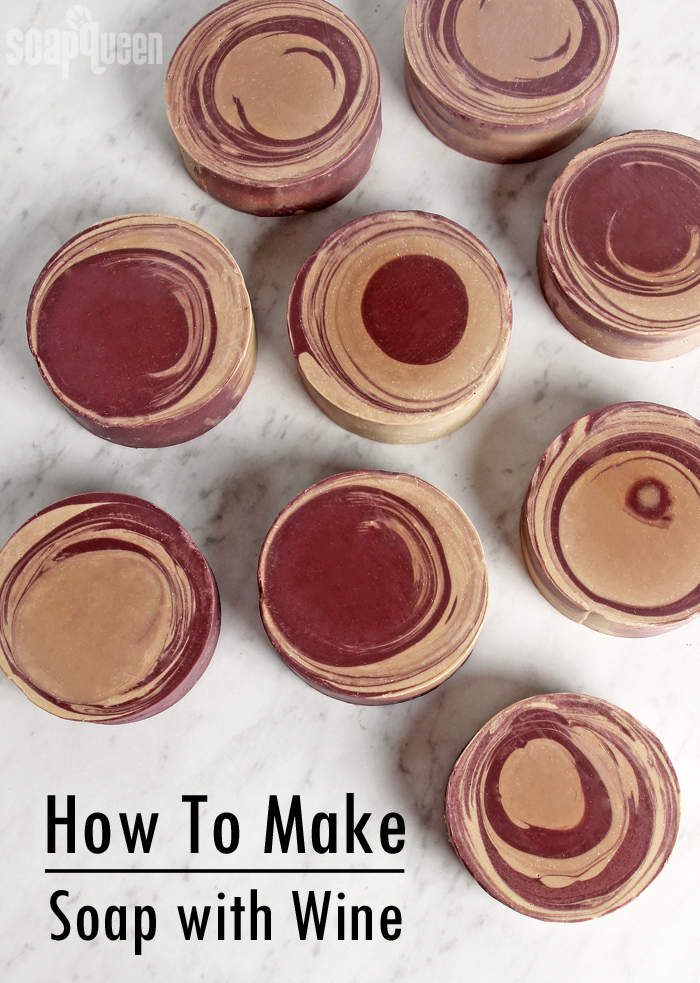

The red wine gives the soap batter a dark tan color. Titanium dioxide combats this a bit, creating a creamier color. A combination of Queen’s Purple Mica and Merlot Sparkle Mica create a rich burgundy-wine color. Berrywine Fragrance Oil gives the soap a realistic and slightly fruity scent. Berrywine Fragrance Oil does not smell great out of the bottle, but it smells good in soap – promise!

Using a local wine is a great way to highlight local ingredients and show off your hometown pride!

Using a local wine is a great way to highlight local ingredients and show off your hometown pride!