This Chopped Embed Soap is inspired by Tania of Soapish. She created three batches of soap with fragrance oils from the Farmers Market Collection that had an embed design – Raspberry Jam, Cucumber Garden, and Blueberry Thyme. We decided to try something similar using bars from various projects, including the 10 Easy Ways to Texture Cold Process Soap video.

The exact colors will depend on what soap you have on hand. The embeds in this batch are made with Aqua Pearl Mica and Blue Mica. You can experiment with the size, shape, and number of embeds. They make up about 30% of the total weight of this recipe.

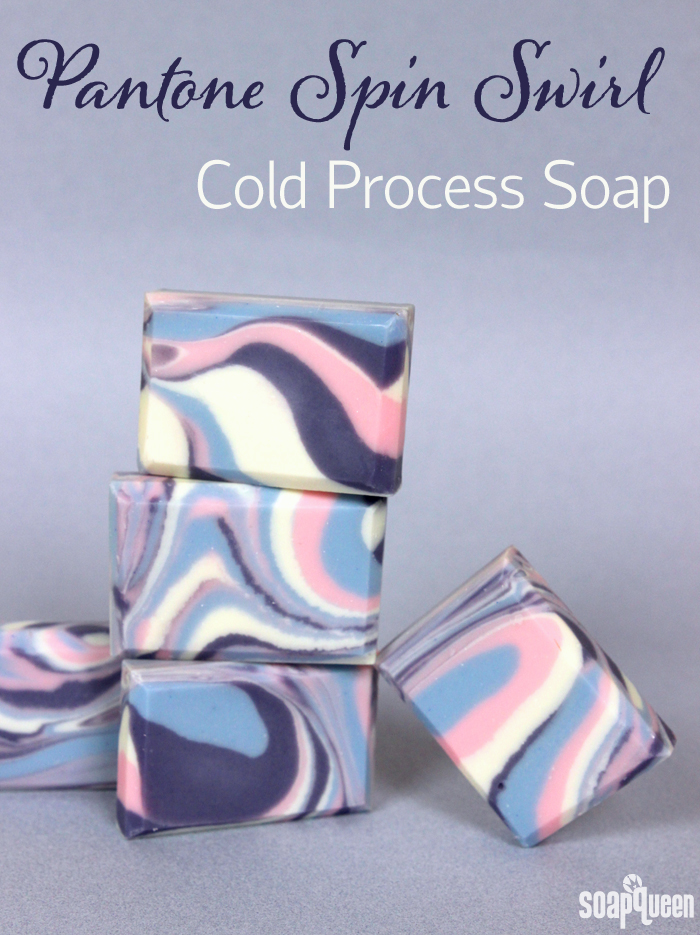

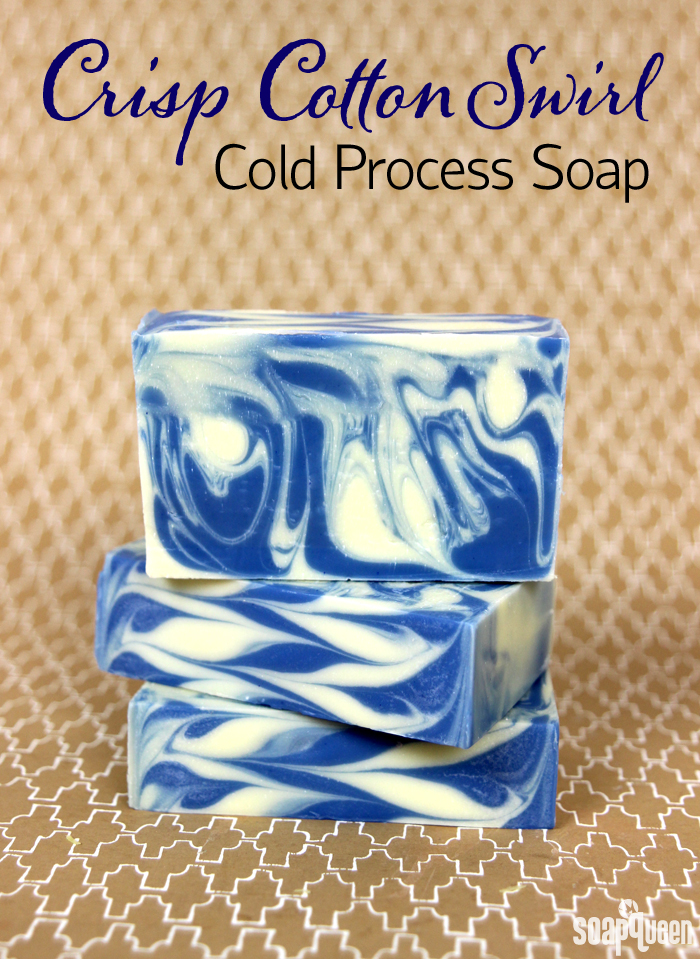

We used Crisp Cotton Fragrance Oil to complement the blue color palette. It’s a favorite around the Bramble Berry office, with notes of raspberry, rose water, thyme, and musk. It behaves well in soap and doesn’t discolor. This recipe has a 10% water discount to prevent glycerin rivers.

Chopped Embed Cold Process Tutorial

What You Need:

5 lb. Wood Mold with Sliding Bottom

Silicone Liner for 5 lb. Mold

38 oz. Lots of Lather Quick Mix

5.5 oz. Sodium Hydroxide Lye

11.3 oz. Distilled Water (10% water discount)

2.5 oz. Crisp Cotton Fragrance Oil

Titanium Dioxide

About 20-25 oz. Premade Cold Process Soap (cut into chunks)

Click below to add everything you need for this project to your Bramble Berry shopping cart!

PREP EMBEDS: Using a sharp knife, chop premade cold process soap into small chunks. The exact size and shape is up to you – our cold process pieces were roughly 0.5 inches. Don’t worry about the pieces being completely uniform – variety in size and shape adds interest.

We used cold process soap that was about 3-4 weeks cured for the embeds. Feel free to use newer or older soap.

If you’ve never made cold process soap before, stop here. We highly recommend checking out our FREE four part SoapQueen.tv series on cold process soapmaking, especially the episode on lye safety. And if you’d rather do some reading, Bramble Berry carries a wide range of books on the topic, including Pure Soapmaking. You can also check out the digital downloads for that instant gratification factor.

FRAGRANCE PREP: Measure 2.5 ounces of Crisp Cotton Fragrance Oil into a small glass container and set aside.

COLORANT PREP: Disperse 3 teaspoons of titanium dioxide into 2 tablespoons of a lightweight liquid oil such as sunflower or sweet almond oil. Use a mini mixer to get rid of clumps.

Optional: To ensure the titanium dioxide blends smoothly into the soap, we recommend micronizing it before dispersing it in oil. Use a coffee grinder to break up any clumps of color and prevent streaks of white from showing in the final soap. We like to use a coffee grinder that has a removable stainless steel mixing area for easy cleaning.

SAFETY FIRST: Suit up for safe handling practices. That means goggles, gloves, and long sleeves. Make sure kids, pets, other distractions, and tripping hazards are out of the house or don’t have access to your soaping space. Always soap in a well-ventilated area.

ONE: Slowly and carefully add 5.5 ounces of lye to 11.3 ounces of distilled water. Gently stir until the lye has fully dissolved. Set it aside to cool. If you’d like a harder bar of soap that releases faster from the mold, you can add sodium lactate to the cooled lye water. Use 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you’d add 2.5 teaspoons sodium lactate.

TWO: Fully melt the entire bag of Lots of Lather until it’s completely clear. Shake the bag to mix up all the oils. Measure 38 ounces into a heat-safe bowl. Once the lye water and the oils have cooled to 130 degrees F or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend the mixture to a thin trace.

THREE: Add the 2.5 ounces of Crisp Cotton Fragrance Oil and use the stick blender to mix in.

FOUR: Add all of the dispersed titanium dioxide. If the soap is still thin, use the stick blender to mix until you reach a medium trace. If the soap is already at medium trace, use a whisk to mix in the colorant.

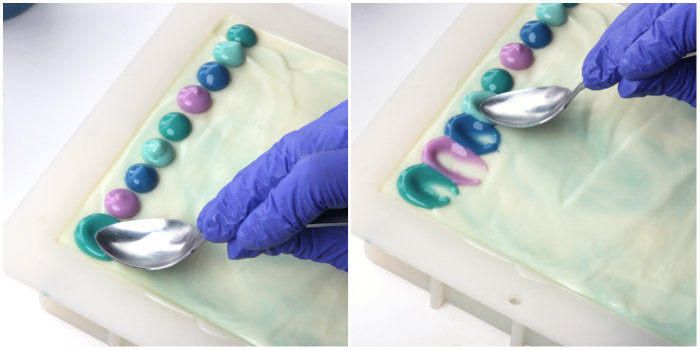

FIVE: Add the cold process embeds into the soap and use a large spatula to thoroughly combine. As you are adding the embeds, separate any pieces that are sticking together.

SIX: Pour the soap into the mold. Tap the mold firmly on the counter to help get rid of any bubbles. Use a large spoon or spatula to smooth the top, and press down any embeds that are sticking out.

SEVEN: Spritz the soap with 99% isopropyl alcohol to prevent soda ash. We didn’t insulate the soap. The lower temperatures and water discount will help prevent glycerin rivers. If you live in an extremely hot climate, you may want to place the mold in to the fridge for several hours to prevent gel phase. Allow the soap to stay in the mold for 1-3 days. Once the soap is firm enough, unmold and cut into bars. Allow to cure for 4-6 weeks and enjoy.

- 5 lb. Wood Mold with Sliding Bottom

- Silicone Liner for 5 lb. Mold

- 38 oz. Lots of Lather Quick Mix

- 5.5 oz. Sodium Hydroxide Lye

- 11.3 oz. Distilled Water (10% water discount)

- 2.5 oz. Crisp Cotton Fragrance Oil

- Titanium Dioxide

- About 20-25 oz. Premade Cold Process Soap (cut into chunks)

- Slowly and carefully add 5.5 ounces of lye to 11.3 ounces of distilled water. Gently stir until the lye has fully dissolved. Set it aside to cool. If you’d like a harder bar of soap that releases faster from the mold, you can add sodium lactate to the cooled lye water. Use 1 teaspoon of sodium lactate per pound of oils in the recipe. For this recipe, you’d add 2.5 teaspoons sodium lactate.

- Fully melt the entire bag of Lots of Lather until it’s completely clear. Shake the bag to mix up all the oils. Measure 38 ounces into a heat-safe bowl. Once the lye water and the oils have cooled to 130 degrees F or below (and are ideally within 10 degrees of each other), add the lye water to the oils and stick blend the mixture to a thin trace.

- Add the 2.5 ounces of Crisp Cotton Fragrance Oil and use the stick blender to mix in.

- Add all of the dispersed titanium dioxide. If the soap is still thin, use the stick blender to mix until you reach a medium trace. If the soap is already at medium trace, use a whisk to mix in the colorant.

- Add the cold process embeds into the soap and use a large spatula to thoroughly combine. As you are adding the embeds, separate any pieces that are sticking together.

- Pour the soap into the mold. Tap the mold firmly on the counter to help get rid of any bubbles. Use a large spoon or spatula to smooth the top, and press down any embeds that are sticking out.

- Spritz the soap with 99% isopropyl alcohol to prevent soda ash. We didn’t insulate the soap. The lower temperatures and water discount will help prevent glycerin rivers. If you live in an extremely hot climate, you may want to place the mold in to the fridge for several hours to prevent gel phase. Allow the soap to stay in the mold for 1-3 days. Once the soap is firm enough, unmold and cut into bars. Allow to cure for 4-6 weeks and enjoy.

The ocean is an abundant source of inspiration. It’s full of color, texture, sounds and smells. For the past two weeks, the ocean influenced a wide range of projects. From eye shadow to cold process soap, the Sweet Sea Dreams projects featured plenty of sparkle, aquatic color schemes and fresh scents.

The ocean is an abundant source of inspiration. It’s full of color, texture, sounds and smells. For the past two weeks, the ocean influenced a wide range of projects. From eye shadow to cold process soap, the Sweet Sea Dreams projects featured plenty of sparkle, aquatic color schemes and fresh scents.