Here in the Pacific Northwest, we are known for our love of coffee. It’s not uncommon to have multiple Starbucks just blocks away from each other. There is also an abundant number of locally-owned coffee shops. If you love coffee as much as a Seattleite, making soap is a great way to include the ingredient in your products. In this coffee soap project, locally roasted coffee is used to really make these bars special. Using a local ingredient highlights the handmade aspect of your products.

Incorporating coffee into cold process soap is easier than you might think. The distilled water in cold process recipes can be swapped for plain coffee. The key is using distilled water to brew the coffee, and allowing the coffee to cool to room temperature before adding sodium hydroxide lye. Using coffee instead of water makes the soap batter quite dark, so keep that in mind when choosing the color palette. If you’re using plain brewed coffee, don’t worry about the soap overheating. Black coffee does not contain sugar.

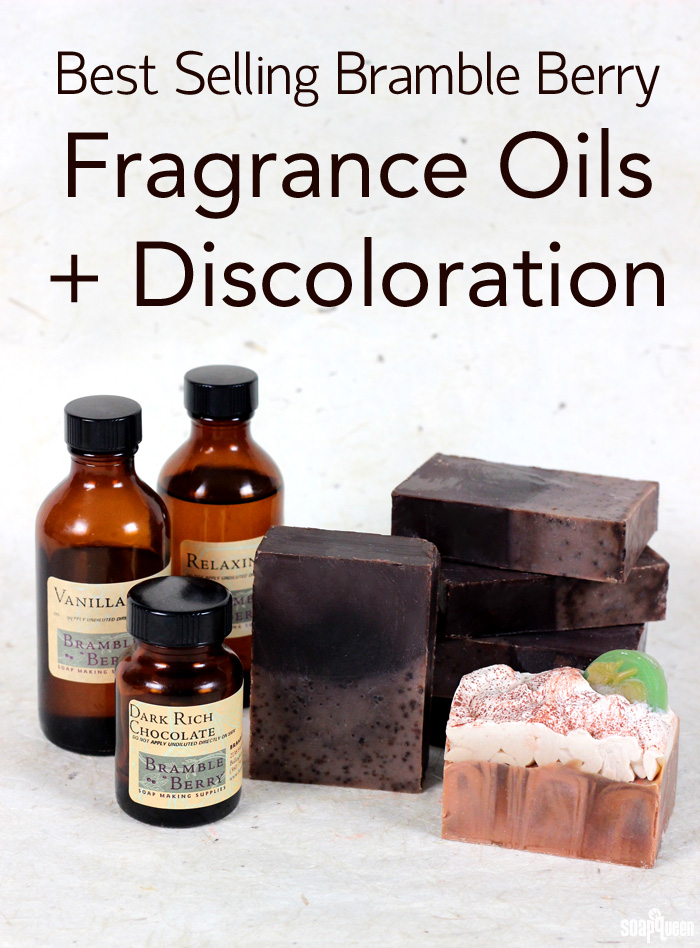

Using coffee instead of water does not give soap a coffee smell. In fact, when you mix lye with coffee it does not smell very pleasant. This is because the lye “scorches” the coffee, resulting in a noticeable odor. The smell of the coffee and lye solution is usually not noticeable in the final bar. This is especially true if you’re using a fragrance oil in your recipe. For this soap, Espresso Fragrance Oil gives the bars a rich, delicious scent. Espresso Fragrance Oil does discolor in cold process soap due to the vanillin content. Titanium dioxide combats that slightly, but you can notice some discoloration on the top of the soap in the photos above and below. Learn more about vanilla discoloration here.

This soap also contains used coffee grounds. It’s important to add used rather than fresh coffee grounds. Fresh coffee grounds may bleed in the soap. The bleeding doesn’t hurt the bars in any way, but it is a cosmetic issue. It’s also a great way to use up leftover coffee grounds!

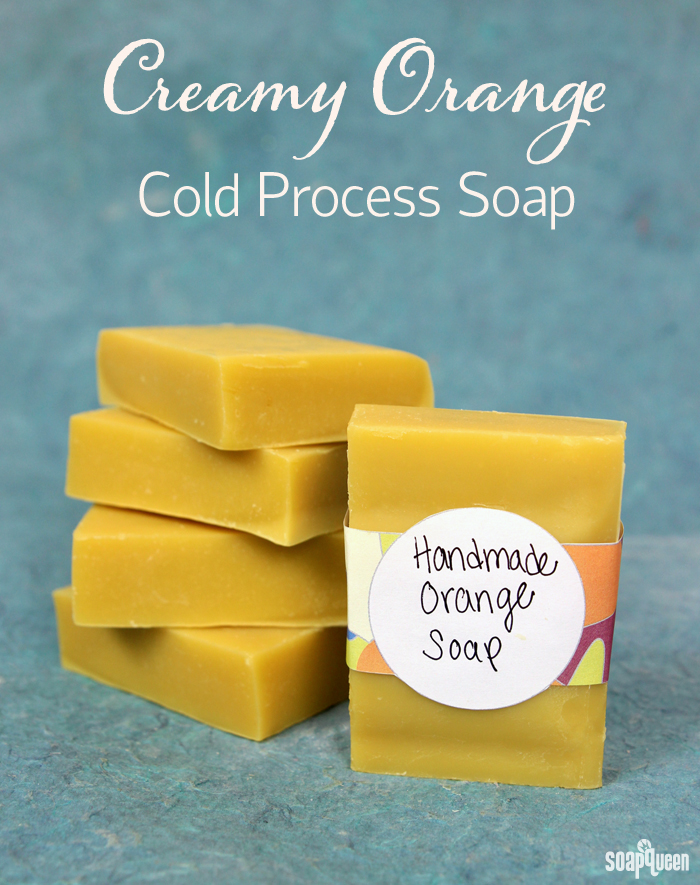

The soap bands shown above are included in the

The soap bands shown above are included in the