Temperature plays a very important part in soaping. It can affect the trace, color, texture and scent of your final soap. In general, we recommend soaping at around 120-130 ° F. This means that both the lye and oil are this temperature range immediately before the two are combined and the saponification process begins.

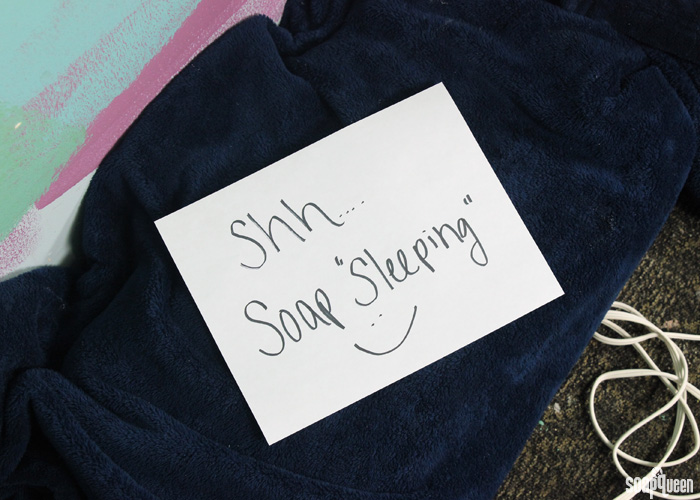

An important factor that affects the temperature of your cold process soap is insulating it after it has been poured into the mold. Insulating the soap involves covering the mold with a lid or homemade device (we often use cardboard) to keep the soap warm. In addition to covering the soap with a lid or cardboard, you can also wrap the mold in a blanket to insulate. For soap that has a textured top, I recommend creating a “tent” with cardboard and cover with a blanket to ensure the top of your soap is not smashed. Below is a soap covered in cardboard and wrapped in a blanket. I always write a little note so people don’t disturb the soap =)

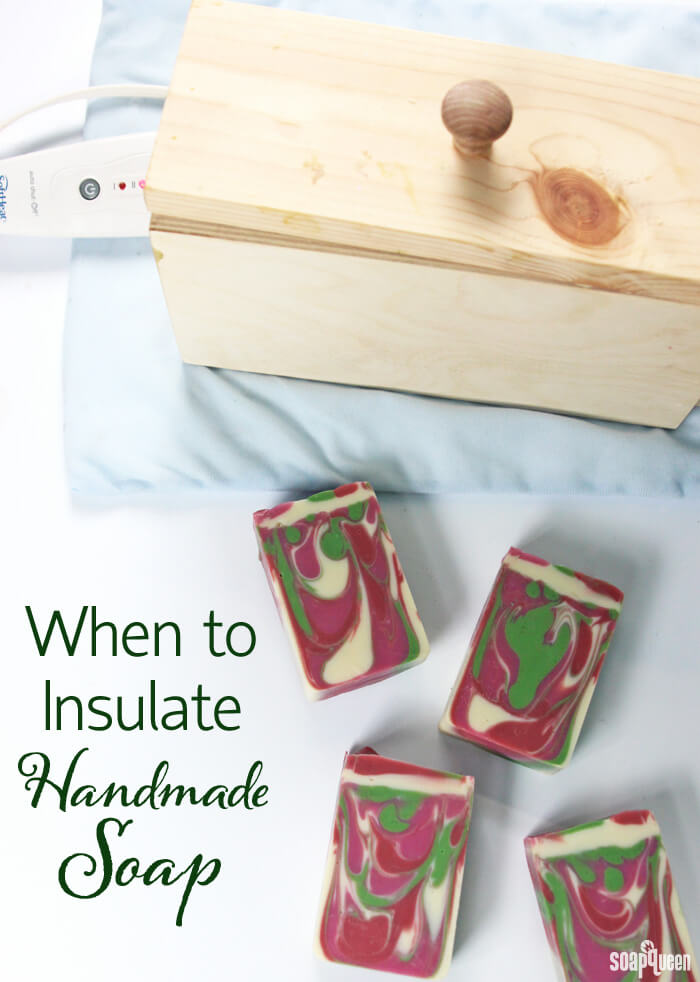

Above, soap is being insulated with a lid and cardboard to promote gel phase.

Above, soap is being insulated with a lid and cardboard to promote gel phase.

[Read more…]