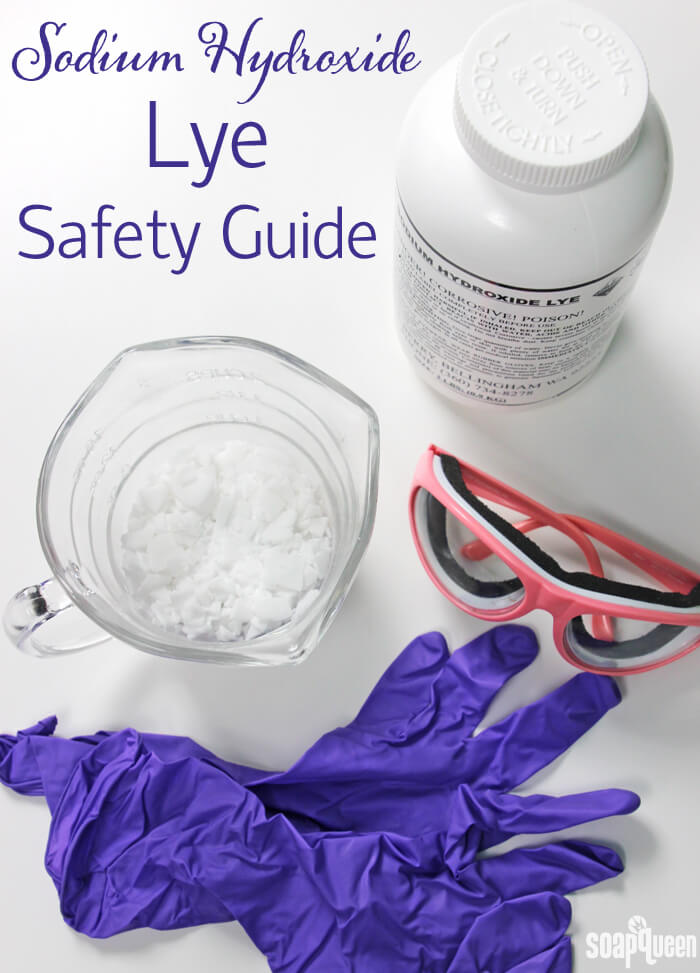

There are many factors to consider when making cold process soap. This week and next week will focus on the basics of soap making. One of the most important parts is safety. When working with sodium hydroxide lye, it is important to wear safety gear like goggles, gloves and long sleeves. With the correct precautions, soaping is a safe process. Learn more in the Back to Basics: Lye Safety Guide.