Cold process soap made with 100% olive oil is known as “Castile” soap. It is thought to originate in the Castile region of Spain – thus the name, Castile soap! Olive oil is a staple soaping oil that can be found in many cold process recipes. Olive oil contributes moisturizing properties to soap. It also gives the bars a gentle and creamy (read: small, lotion-like) lather, making it a great choice for dry or sensitive skin.

When you create soap with only olive oil (Castile soap), the batter takes quite a while to come to trace. Castile soap also takes longer to harden in the mold than most cold process recipes that contain hard oils like palm or coconut. In fact, Castile soap can require up to two weeks in the mold before it can be removed! But, there are a few tricks to help Castile soap harden more quickly. This recipe has a 20% water discount, which helps the soap harden much faster. To learn more about how and when to water discount recipes, click here.

Another trick for hardening Castile soap more quickly is sodium lactate. Sodium lactate is the sodium salt of lactic acid. It’s commonly used as a food preservative, and is also used in lotion recipes for its humectant properties. When added to lye water, sodium lactate helps cold process soap harden faster. I use it in almost all my cold process batches, especially when using a silicone mold. The usage rate is 1 teaspoon sodium lactate per pound of oils in the recipe. It’s an optional step but I highly recommend it, especially for this recipe! Learn more about sodium lactate here.

The final trick to helping this soap harden in the mold faster is gel phase. ‘Gelling’ and ‘gel phasing’ in cold process soap refers to a part of the saponification (soapmaking) process where the soap gets warm and gelatinous – up to 180 degrees. Heat speeds up the saponification process. Hot process soap, for example, can be cut usually within one day, and can be used right away. Soaping on the warmer side (about 130 ° F) and insulating the soap for 24 hours helps promote gel phase. If your room is cold, you may want to place the soap on a heating pad to keep it warm. Learn more about gel phase here. With a 20% water discount, sodium lactate and gelling, I was able to unmold and cut this soap in 2 days.

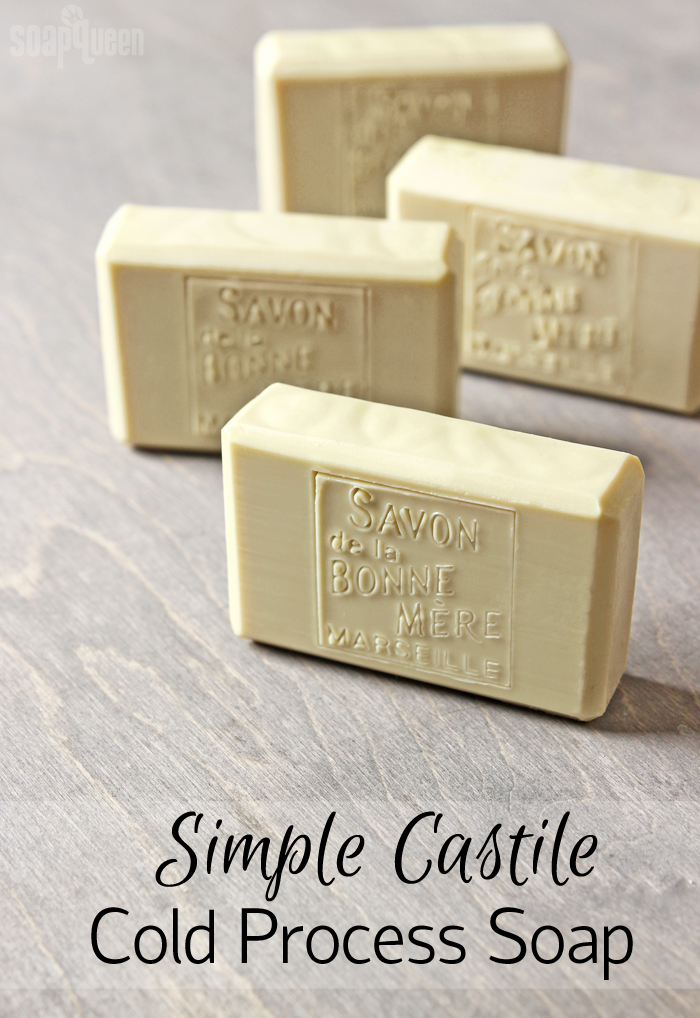

This soap is simple with no colorants or design elements. To give the soap a little interest, I stamped each bar with the Savon Soap Stamp. Savon de Marseille (aka: Marseille soap) is traditional soap made from vegetable oil and olive oil in Marseille, France. I thought it was very fitting for this recipe! For tips on stamping soap, check out this video. I scented this batch with Tomato Leaf Fragrance Oil, which is a wonderfully herby, green and fresh fragrance.