Soft and luxurious, silk is produced from caterpillar-like insects called silk worms. In bath and body products, liquid silk and Tussah silk fibers are added for a soft “silky” feel. Liquid silk is perfect for water based products such as lotion and emulsified scrubs. Small amounts can also be added to melt and pour soap. Tussah silk fibers can be dissolved in your lye solution and added to cold process soap.

Soft and luxurious, silk is produced from caterpillar-like insects called silk worms. In bath and body products, liquid silk and Tussah silk fibers are added for a soft “silky” feel. Liquid silk is perfect for water based products such as lotion and emulsified scrubs. Small amounts can also be added to melt and pour soap. Tussah silk fibers can be dissolved in your lye solution and added to cold process soap.

The silk making process starts once the silkworm begins to construct its cocoon. Silkworm have glands on the mouth part of their body that produce a clear, proteinaceous fluid called fibroin. This fluid becomes hard once exposed to air. The silkworm rotates its body in a figure-8 motion while producing the protein material, which forms a cocoon around its body. Building the cocoon takes about 3-8 days.

Once the cocoon is complete, the silk can be harvested. In order to obtain the longest strands of silk fiber, some silk is harvested by boiling the cocoons with the worms inside. Tussah silk fiber sold at Bramble Berry is cruelty free and collected after the worms have left their cocoons. That causes the fibers to be short.

Left to right: Liquid Silk, Tussah Silk Fiber

Left to right: Liquid Silk, Tussah Silk Fiber

The addition of Tussah silk fibers to cold process soap gives a luxurious “silky” feel. It also contributes to a slightly more shiny appearance and is great from a marketing standpoint. Because silk fibers are a little tricky to weigh or measure precisely, we recommend a small pinch per pound of soap.

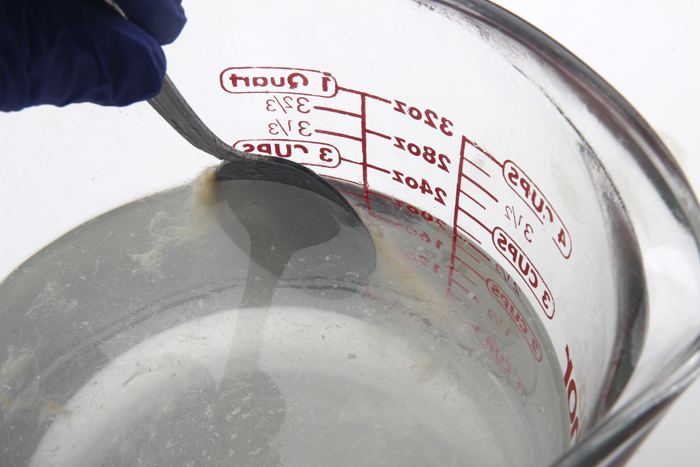

To use the silk fibers, add them directly into your lye solution, immediately after the lye is dissolved. Your lye water should be around 170-190 ° F. The hotter the lye solution, the easier the fibers will dissolve. Then, stir, stir stir…and keep stirring! This process will take several minutes.

You’ll notice immediately that some of the fibers will start to dissolve. But, some of the fibers may clump together. If this happens, firmly press the clump against the container with your spoon to break it up. Breaking the clump apart will help the silk to dissolve faster.

You’ll notice immediately that some of the fibers will start to dissolve. But, some of the fibers may clump together. If this happens, firmly press the clump against the container with your spoon to break it up. Breaking the clump apart will help the silk to dissolve faster.

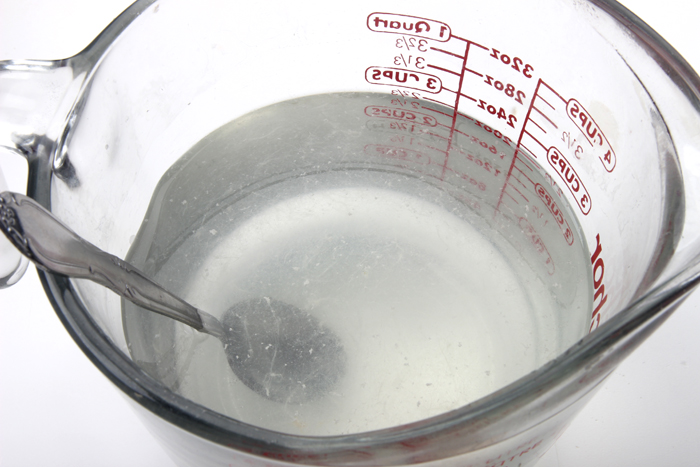

You may notice very small pieces of the lye fibers still in your lye mixture. This is fine. Allow your lye mixture to cool and use as normal.

You may notice very small pieces of the lye fibers still in your lye mixture. This is fine. Allow your lye mixture to cool and use as normal.

Liquid silk can also be used in cold process soap up to 5%. Because the liquid silk it already dissolved, you can add it directly to your soap at trace. When making emulsified scrubs or lotions, add the silk with a usage rate of 1% during the water phase. If adding to melt and pour, add the liquid silk at a rate of 1/2 tsp. per pound of melt and pour soap.

Liquid silk can also be used in cold process soap up to 5%. Because the liquid silk it already dissolved, you can add it directly to your soap at trace. When making emulsified scrubs or lotions, add the silk with a usage rate of 1% during the water phase. If adding to melt and pour, add the liquid silk at a rate of 1/2 tsp. per pound of melt and pour soap.

If you’re looking for some lotion or scrub recipes to use your liquid silk, check out the Soaks & Scrubs and Lotion categories. The Emulsified Sugar Scrub tutorial on Soap Queen TV would be perfect for liquid silk; simply add the silk into the distilled water. Liquid silk would feel fantastic in the Rose & Aloe In-Shower Lotion as well.

Have you used liquid silk or Tussah silk fibers in your soapy projects? I would love to hear what you thought of it!